PaRMC Foundry, tinotora akawanda mamwe maitiro ekukanda masimbi uye alloys sezvinodiwa nemutengi kana zvichienderana nebudiriro yedu. Yakasiyana simbi uye alloy yakakodzera kune yayo yakanakisa castings process uchifunga nezvekupedzisira-mushandisi zvinodiwa uye mutengo unoshanda. Somuenzaniso, thegrey cast ironkazhinji yakakodzera kukandwa nayojecha kukanda nzira, ukuwosimbi isina ngurainowanzokandwa nekurasika wax investment cast.

Pane zvinhu zvakawanda zvatinofanira kufunga nezvazvo kana tikasarudza nzira dzekukanda dzakakodzera, sekukandwa kwemidziyo, kudiwa kwehuremu (Aluminium neZinc alloys dzakareruka kupfuura mamwe maalloys), michina zvivakwa uye kana paine chakakosha chinodiwa kuita mukati. kupfeka kuramba, corrosion resistance, damping...etc. Kana tikasarudza iyoprecision casting(kazhinji inotaura nezvekudyara kwekudyara), pachave nekushomeka kana kusadaMachining, iyo inogona kuchengetedza mutengo wese wekugadzira zvakanyanya.

Nekuda kweruzivo rwedu rwakapfuma uye michina yakanyatso kurongeka, tine sarudzo dzakasiyana dzecastings kune akasiyana maindasitiri. Zvatino hunyanzvi zvinonyanya kukanda jecha, kukanda mari, kukanda magokokurasika furo, vacuum casting uye CNC machining. Ose ari maviri maOEM tsika masevhisi uye yakazvimirira R&D anowanikwa kufekitori yedu. Iyo nyanzvi yeinjiniya ndiyo yedu yakakosha kukwikwidza.

Anopfuura zana emhando dzesimbi uye alloys anokandwa panzvimbo yedu yekutanga. Iwo anonyanya kusiyanisa grey cast iron,ductile cast iron, simbi inogadzirwa nekabhoni simbi,alloy simbi, simbi isina tsvina uye aruminiyamu nemhangura alloys. Naizvozvo, kubva pasevhisi yedu, mese munogona kusarudza iyo chaiyo yekukanda maitiro uye zvigadzirwa kusangana nechikumbiro chako chekuremekedza. Vazhinji vedutsika yekukanda zvikamuvari kushandira akasiyana siyana emakanika uye maindasitiri vanobatana kubva kuEurope, America, Asia, Australia uyezve, kuChina.

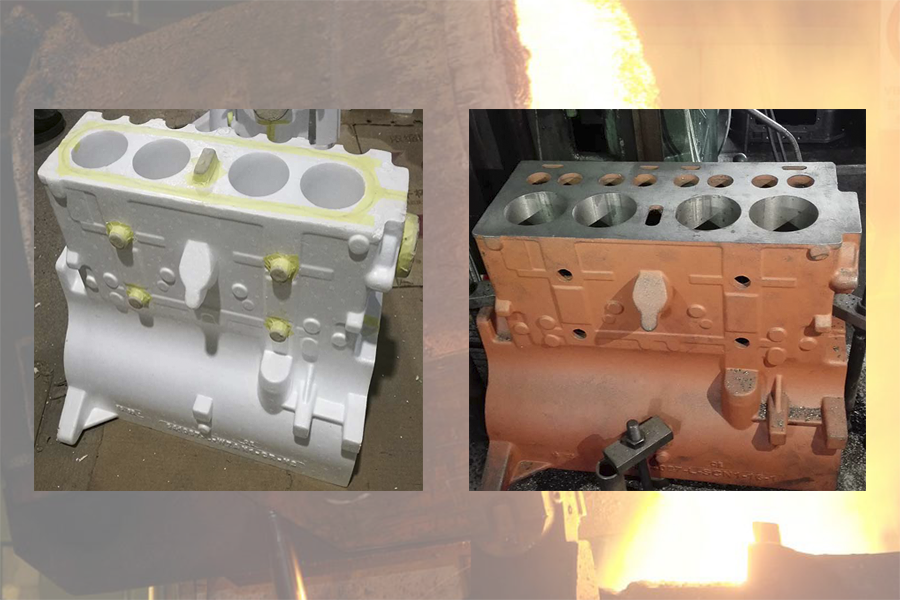

Kukandwa kwejecha kunotora huwandu hukuru muhuremu hwese maitiro ekukanda. Gray iron, ductile iron, ndarira, simbi uye aruminiyamu ndiwo makuru ekukanda alloys.

Kunodaidzwawo kunzi kurasika wakisi kukanda kana kukanda chaiko, kukanda kwekudyara kunosvika pakurongeka kwepamusoro mu geometrical uye dimension tolerances.

Shell mold casting inoshandisa resin pre-yakavharwa jecha kugadzira mold. Inogona kukanda zvirinani zvirinani pamusoro uye dimensional pane kukanda jecha.

Yakarasika foam casting, iyo inodaidzwa zvakare kunzi yakazara mold casting kana cavityless mold casting, inoita basa rakakosha mukukandwa kwakakura uye kwakakora-madziro.

Vacuum casting inodaidzwa zvakare kuti s V maitiro ekukanda, yakavharwa mold kukanda kana kusasimba kukanda. Inofarirwa kune chigadzirwa chakakura uye chakakora-madziro castings.

Kune mamwe mativi esimbi chaiwo, CNC chaiyo machining inzira inodzivisika mushure mekupedzwa kuumbwa kwawanikwa.

| Kukandira Kugona paRMC Foundry | ||||||

| Casting Process | Kwegore Kugona / Matani | Main Materials | Kukanda Uremu | Dimensional Kushivirira Giredhi reCastings (ISO 8062) | Kupisa Kurapa | |

| Green Sand Kukanda | 6000 | Cast Grey Iron, Cast Ductile Iron, Cast Aluminium, Brass, Cast Steel, Stainless Simbi | 0.3 kusvika 200 kg | CT11~CT14 | Normalization, Kudzima, Tempering, Annealing, Carburization | |

| Shell Mold Casting | 0.66 lbs kusvika 440 lbs | CT8~CT12 | ||||

| Yakarasika Wax Investment Kukanda | Mvura Girazi Kukandira | 3000 | Simbi isina ngura,Carbon Steel, Steel Alloys, Brass, Cast Aluminium, Duplex Stainless Steel | 0.1 kusvika 50 kg | CT5~CT9 | |

| 0.22 lbs kusvika 110 lbs | ||||||

| Silica Sol Casting | 1000 | 0.05 kusvika 50 kg | CT4~CT6 | |||

| 0.11 lbs kusvika 110 lbs | ||||||

| Yakarasika Foam Kukanda | 4000 | Grey Iron, Ductile Iron, Steel Alloys, Carbon Steel, Stainless Simbi | 10 kusvika 300 kg | CT8~CT12 | ||

| 22 lbs kusvika 660 lbs | ||||||

| Vacuum Casting | 3000 | Grey Iron, Ductile Iron, Steel Alloys, Carbon Steel, Stainless Simbi | 10 kusvika 300 kg | CT8~CT12 | ||

| 22 lbs kusvika 660 lbs | ||||||

| High Pressure Die Casting | 500 | Aluminium Alloys, Zinc Alloys | 0.1 kusvika 50 kg | CT4~CT7 | ||

| 0.22 lbs kusvika 110 lbs | ||||||