Investment Casting Foundry

Investment casting, inozivikanwawo sekurasika kukanda wakisi kana kukanda kwakaringana, inzira yave ichiitwa kwezviuru zvemakore, nekurasika wakisi iri imwe yenzira dzekare dzinozivikanwa dzekugadzira simbi.

Nekuda kwechimiro chakaomesesa muchiyero uye geometric, iyo mari yekukanda inogadzirwa kuti isvike mambure chimiro kana padyo net mambure, kuderedza kudiwa kwechipiri maitiro senge lathing, kutendeuka kana zvimwe.CNC machiningprocess.

Investment casting inzira yekugadzira iyo inogona kuteedzerwa kumashure pamusoro pe5,000 makore apfuura. Kubva ipapo, apo wakisi yakagadzira patani, kusvika kune yanhasi tekinoroji yakakwira wax, zvigadziriso uye alloys akakosha, iyo yakarasika yakisi yekukanda inoita kuti zvikamu zvemhando yepamusoro zvinogadzirwa zvine zvakanakira kurongeka, kudzokorora, uye kuvimbika.

Investment casting inowana zita rayo kubva pakuti iyo pateni inoiswa mari, kana yakakomberedzwa, ine refractory zvinhu. Mapatani ewakisi anoda kutariswa zvakanyanya nekuti haana kusimba zvakakwana kuti amirire masimba anosanganikwa nawo panguva yekugadzira mold.

Investment Casting Foundry

Zvatinogona Kuwana nekurasika Wax Investment Casting

Yakarasika wakisi yekudyara mari ine silica sol sebinder material inogona kusvika dimensional tolerance giredhi CT4 ~ CT7 zvinoenderana neISO 8062. Midziyo yedu yakarongeka zvakazara uye automation process control control inobvumira kuenderana uye kudzokororwa kushivirira pedyo se± 0.1 mm. Thezvikamu zvekukandira wakisi zvakarasikainogona zvakare kugadzirwa muhukuru hwakakura, inogona kunge idiki se 10 mm kureba x 10 mm yakafara x 10 mm kureba uye huremu hushoma se0.01 kg, kana yakakura se1000 mm kureba uye huremu hunosvika 200 kg. .

RMC iindasitiri inotungamira mugadziri wepamusoro-mhando yekudyara castings yakazvipira kuendesa yakanakisa mhando, kukosha kwepamusoro uye yakasarudzika ruzivo rwevatengi. RMC ine ruzivo, hunyanzvi hwehunyanzvi uye magadzirirwo emhando yekusimbisa uye nekuvimbika kuendesa huwandu hwakakura hwekukanda nekumwe kugadzirisa.

- • Hukuru hweKukanda: 1,000 mm × 800 mm × 800 mm

- • Cast Weight Range: 0.5 kg - 200 kg

- • Kugona Kwepagore:3,000 matani

- • Bond Materials for Shell Building:Silica Sol, Mvura Girazi kana musanganiswa wavo.

- • Casting Tolerances:CT4 ~ CT7 maererano ne ISO 8062 kana pane Chikumbiro.

Kugadzira Shell Panguva Yekudyara Kwemari

Ndeapi Masimbi uye Alloys atinogona Kudurura ne Investment Casting

TheInvestment casting foundrypaRMC inokwanisa kusangana nemhando dzakasiyana siyana dzearoyi zvinyorwa uye zvakatemwa zvinoenderana neASTM, SAE, AISI, ACI, DIN, GOST, EN, ISO, uye GB zviyero. Tine anopfuura zana akasiyana ferrous uye asiri-ferrous alloys ayo isu tinokanda nawo zvikamu tichishandisa yakaoma dhizaini chimiro.

- • Grey Cast Iron:HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30, GG40; ASTM A48 Gray Iron Magiredhi Kirasi 20, Kirasi 25, Kirasi 30, Kirasi 35, Kirasi 40, Kirasi 45, Kirasi 50, Kirasi 55, Kirasi 60.

- • Ductile Cast Iron (Nodular Iron):China GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2; GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-400-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN- GJS-800-2; ASTM A536 Ductile Iron Grades 60-40-18, 65-45-12, 70-50-05, 80-60-03, 100-70-03, 120-90-02.

- •Carbon Steel:AISI 1020 ~ AISI 1060, C30, C40, C45.

- •Alloy Steel:ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo, nezvimwewo.

- •Simbi isina ngura:AISI 304, AISI 304L, AISI 316, AISI 316L,AISI 347, AISI 430, 1.4401, 1.4404, 1.4408, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571, CF3, CF3M, CF8, CF8M... nezvimwewo.

- •Duplex Stainless Simbi (DSS)uyeKunaya Kuomesa (PH) Stainless Simbi

- • Brass, Bronze uye mamwe Copper-based Alloys

- •Nickel Based Alloy (Inconel 625, Inconel 713, Inconel 718 nezvimwewo), Cobalt Yakavakirwa Alloys

- • Simbi isingadziviriri, Simbi isingagamuchirwi nemvura yegungwa, Simbi yepamusoro-soro, Simbi yakakwira, Duplex Stainless Steel.

- • Aluminium Alloy A356, A360

- • Mamwe Alloys sechikumbiro kana maererano neASTM, SAE, AISI, GOST, DIN, EN, ISO, uye GB.

Stainless Steel Investment Casting

Investment Casting Mold

Al Mold yeKurasika Wax Kukanda

Metal Mold ye Investment Casting

Yakanyatsogadzirwa Aluminium Alloy Mold ye Precision Casting

Nhanho dzekurasika Wax Investment Casting

Investment casting inzira yakawanda-nhanho inoburitsa pedyo-net chimirokunyatsokandira zvikamu. Kuita kunotanga nekubayiwa wakisi mudhifi kugadzira patani yechigadzirwa chapera. Mapateni acho anonamirwa kune wax runner bars kugadzira cluster.

Munguva yekudyara kwekudyara, muchina wakasarudzika unonyudza sumbu kakawanda muslurry kugadzira goko receramic, uye ipapo wakisi inobviswa muutsi autoclave. Kana wakisi yabviswa, goko receramic rinotungidzwa robva razadzwa nesimbi yakanyungudutswa kugadzira chikamu. Imwe mukana wekukanda mari ndeyekuti wakisi inogona kushandiswa zvakare.

Investment casting (Yarasika wakisi yekukandira maitiro) inoda simbi kufa (kazhinji mualuminium), wakisi, ceramic slurry, choto, simbi yakanyungudutswa, nemimwe michina inodiwa pakubaya jekiseni, kuputika kwejecha, kudonha, kucheka, nekukuya. Iyo Investment casting process inonyanya kusanganisira anotevera matanho:

1- Metal Die Kugadzira

Zvichienderana nedhirowa uye zvinodiwa zvechikamu chinodiwa chakakandwa, simbi inofa kana mold, kazhinji mualuminium, ichave yakagadzirwa uye inogadzirwa. Iyo mhango ichaumba saizi yakafanana uye chimiro cheinodiwa chikamu chakakandwa.

2- Wax Jekiseni

Iyo inozivikanwawo semagadzirirwo epateni, Yarasika wakisi yekukanda mapatani inogadzirwa nekubaya jekiseni rakanyungudutswa musimbi inofa pamusoro.

3- Slurry Assembly

Mapatani ewakisi anobva asungirirwa pagating system, iyo inowanzova seti yemigero iyo simbi yakanyunguduka inoyerera ichienda kune mold. Mushure meizvi, chimiro chakafanana nemuti chinoumbwa, chakakodzera kugadzirwa kwehuwandu.

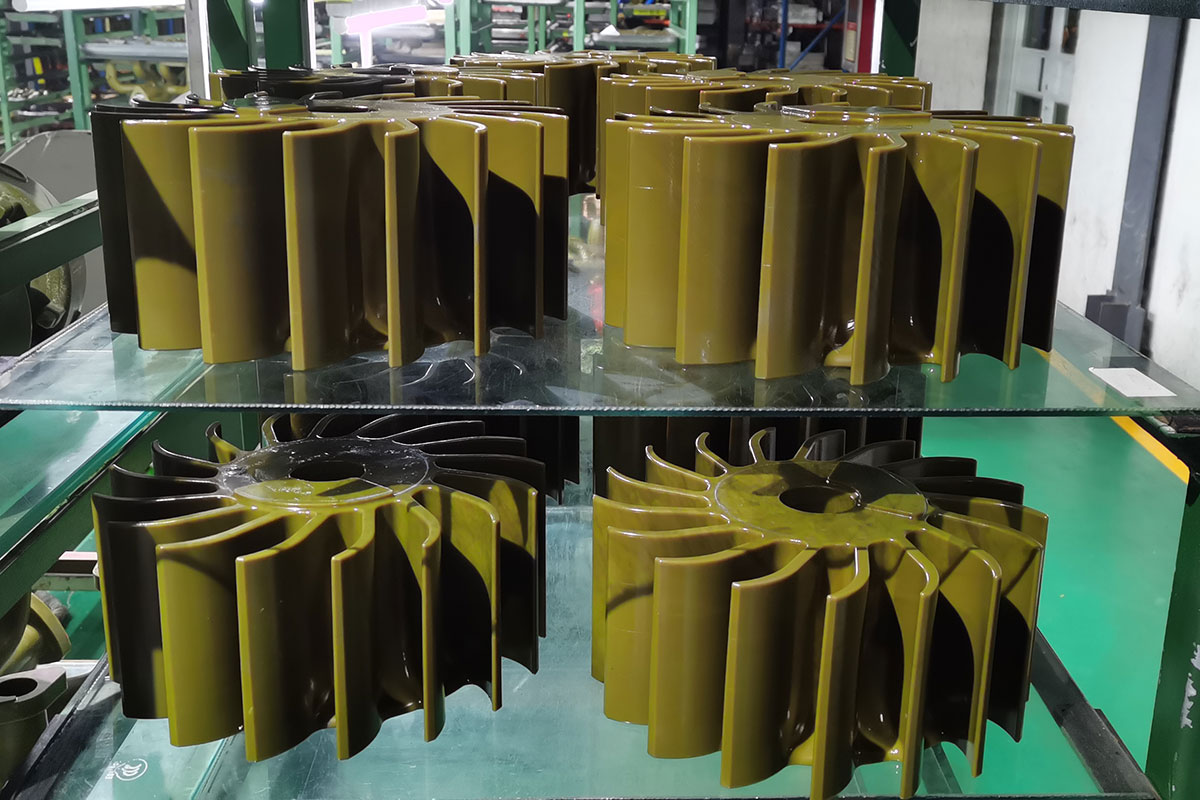

4- Shell Building

Iyo yekudyara inokandira yekunze shell casing inovakwa kuburikidza nekunyudzwa mubhavhu receramic uye ipapo ipapo yakaputirwa nejecha kakawanda.

5- De-waxing

Iyo yemukati mhango yekukandira mari yekudyara inozobviswa dewax, iyo inosiya buri rekunze receramic shell layer. Makomba anongova nzvimbo imwe chete neinoda castings.

6-Pre-Pouring Analysis

Pre-pouring analysis inoreva kuti chiwanikwa chinoda kutarisa nekuongorora kemikari yesimbi yakanyungudutswa kuona kuti inokwana nhamba dzinodiwa here kana kuti starard. Dzimwe nguva, kuongorora uku kwaizoitwa kakawanda.

7- Kudira & Solidification

Iyo ceramic shell ine mhango inofanira kunge isati yapisa isati yadururwa. Izvi zvinodzivirira kuvhunduka uye ganda receramic kubva pakutsemuka kana simbi yemvura pane tembiricha yadururwa mugomba.

8- Kucheka kana Kucheka

Kana simbi ichinge yatonhorerwa uye kusimba, chikamu chakakandwa (s) chinozobviswa kubva kugeji system yemuti cluster kuburikidza nekudedera, kucheka kana kukweshera kubva kune yega yakakandwa chikamu.

9- Shot Blasting uye Sekondari Processing

Chikamu chekukanda chinobva chagadziridzwa zvizere kuburikidza nekukuya kana kuwedzera kupisa kurapwa. Sekondari machining kana kurapwa kwepamusoro kunogonawo kudikanwa zvichienderana nezvinodiwa zvechikamu.

10-Kurongedza uye Delivery

Ipapo iyo yakarasika yekukanda wakisi zvikamu zvichayedzwa zvizere kune zviyero, pamusoro, zvivakwa zvemakanika uye zvimwe zvinodiwa bvunzo usati warongedza uye kuendesa.

Wax Patterns

Shell Drying

Kutonhodza uye Solidification

Kukuya uye Kuchenesa

Maonero atinoita Investment Castings

- • Spectrographic uye manual quantitative analysis

- • Metallographic analysis

- • Dimensional bvunzo

- • CMM

- • Brinell, Rockwell uye Vickers kuoma kwekuongorora

- • Kuongororwa kwemidziyo yemagetsi

- • Low uye zvakajairika tembiricha kukanganisa kuedza

- • Kuongororwa kweutsanana

- • UT, MT uye RT kuongorora

- • Staic uye Dynamic Bancing

- • Kuisa Chisimbiso uye Kuedza Kudzvinyirira

Wax Replicas

Ndezvipi Zvishandiso Zvatinovimba Nazvo Zvekutsvaga Investment

Toolings Warehouse

Wax Patterns Jekiseni

Wax Patterns Jekiseni

Wax Jekiseni Machine

Kugadzira Shell

Kugadzira Shell

Shell Drying Workshop

Shell ye Investment Casting

Shell Drying

Shell Yakagadzirira Kukandira

Kutonhodza uye Solidification

Investment Casting Process

Ndeapi Maindasitiri Yedu Yekudyara Castings Ari Kushandira

Zvikamu zvakaitwa nekukanda marianoshandiswa kukanda zvakasiyana siyana zvezvinhu, zvinosanganisira zvemhando yepamusoro, zvepamusoro mashandiro emaindasitiri ezvimiro zvakaomarara.Iko kushandiswa kwezvikamu zvekukanda mari inovhara akasiyana maindasitiri, mukambani yedu anowanzo shandiswa munzvimbo dzinotevera:

| •Vavha uye Pombi Zvikamu | • Logistics Equipment |

| • Heavy Duty Trucks | • Zvekurima |

| • Zvemotokari | •Hydraulics |

| • Zvishandiso zvekuvaka | • Zvitima zveRailroad |

Zvikumbiro zve Investment Castings

TypicalInvestment CastingsTiri Kugadzira

Tinogona Kuita Zvakawanda nekupa Investment Casting uye Mamwe masevhisi:

PaRMC, isu tinodada nekupa vatengi vedu sevhisi kubva patter dhizaini kusvikakupedza castingsuye yechipiri maitiro. Masevhisi edu anosanganisira:

- -Pateni Dhizaini uye Mutengo Pazasi Mazano.

- - Prototype Development.

- -Kugadzira Tsvagiridzo uye Kubudirira.

- - Manufacturing Flexibility.

- -Kufanirwa uye Kuedzwa.

- - Kurapa Kupisa uye Kurapa Kwepamusoro kunowanikwa.

- - Outsourcing Manufacturing kugona

Stainless Steel Investment Castings

Nei Iwe Unosarudza RMC Yekugadzira Investment Castings

Pane zvikonzero zvakati kuti usarudze RMC sesosi yako yekudyara castings. Paunoita sarudzo, unogona kuva nehanya nezve anotevera mapoinzi atinoshanda zvakanaka pakushandira:

- -Injiniya timu ine nhengo dziri kutarisa simbi yekukanda munda.

- -Kuwedzera ruzivo neakaomesesa geometries zvikamu

- - Huwandu hwakawanda hwezvinhu, zvinosanganisira ferrous uye kwete-ferrous alloys

- - MumbaCNC machiningkugona

- -Kumwe-kumira mhinduro dzekudyara castings uye yechipiri maitiro

- - Hunhu hunoenderana hwakavimbiswa uye hunoenderera mberi nekuvandudzwa.

- -Kushandira pamwe kunosanganisira vagadziri vezvishandiso, mainjiniya, muvambi, machinist uye matekiniki ekugadzira.