Ferritic Stainless simbi inoreva simbi isina tsvina ine body-centered cubic ferrite sechimiro chematrix pakupisa kwepamusoro uye tembiricha yakajairika. Ferritic Stainless simbi ine iron uye chromium sezvinhu zvikuru, kazhinji haina nickel, uye mamwe ane shoma molybdenum, titanium kana niobium nezvimwe zvinhu. Iyo ine yakanaka oxidation kuramba, corrosion resistance uye chloride corrosion cracking resistance. Uye zvakare, ferritic Stainless simbi zvakare ine hunhu hwekupisa kwemafuta conductivity, diki yekuwedzera coefficient, yakanaka oxidation kuramba, uye yakanakisa kushushikana kwecorrosion kuramba. Inonyanya kushandiswa kugadzira zvikamu zvinopikisa mumhepo, mvura mhute, mvura, uye oxidative acid corrosion. Anomiririra mamakisi e ferritic simbi isina tsvina ndeaya: AISI 410 (UNS S41000), AISI 420 (UNS S42000), AISI 430 (UNS S43000) maererano neASTM; 1.4006, 1.4021, 1.4016, maererano neEN standard...etc.

Ferritic Stainless simbi inogona kukamurwa kuita yakaderera chromium, yepakati chromium uye yakakwira chromium zvichienderana neiyo chromium yemukati. Zvinoenderana nekuchena kwesimbi, kunyanya zviri mukati kabhoni uye nitrogen tsvina, inogona kukamurwa kuita yakajairwa ferritic simbi isina tsvina uye Ultra-pure ferritic simbi isina tsvina. Ordinary ferritic Stainless simbi ine zvayakaipira yekudzikira tembiricha uye kamuri tembiricha brittleness, notch senitivity, yakakwira intergranular corrosion maitiro, uye kushomeka weldability. Kunyange zvazvo rudzi urwu rwesimbi rwakagadzirwa kare, kushandiswa kwayo kwemaindasitiri kwakaganhurirwa zvikuru. Uku kushomeka kweakajairwa ferritic Stainless simbi kune hukama nekuchena kwesimbi, kunyanya iyo yakakwirira yezvinhu zvemukati senge kabhoni nenitrogen musimbi. Chero bedzi kabhoni nenitrogen musimbi zvakaderera zvakakwana, zvikanganiso zviri pamusoro zvinogona kukundwa.

Kuenzaniswa neaustenitic simbi isina tsvina, ferritic Stainless simbi ine zvirinani kusaita ngura, kupisa kupisa uye processability. Sezvo chikamu cheferrite chisingakwanisi kunyungudutsa kabhoni, ferrite ine hunhu hwekuve munyoro uye nyore kudzima. Kunge martensitic Stainless simbi, sezvo retice chimiro chiri chemuviri-chepakati cubic chimiro, iri paramagnetic, saka ferritic Stainless simbi ine magineti. Austenitic Stainless simbi haisi-magineti nekuda kweiyo face-centered cubic structure.

Mutengo weferritic simbi isina tsvina hausi chete yakaderera uye yakagadzikana, asiwo ine zvakawanda zvakasiyana uye zvakanakira. Zvave zvichiratidzwa kuti ferritic Stainless simbi inonyatso Yakanakisa imwe nzira.

Ordinary ferritic simbi isina tsvina

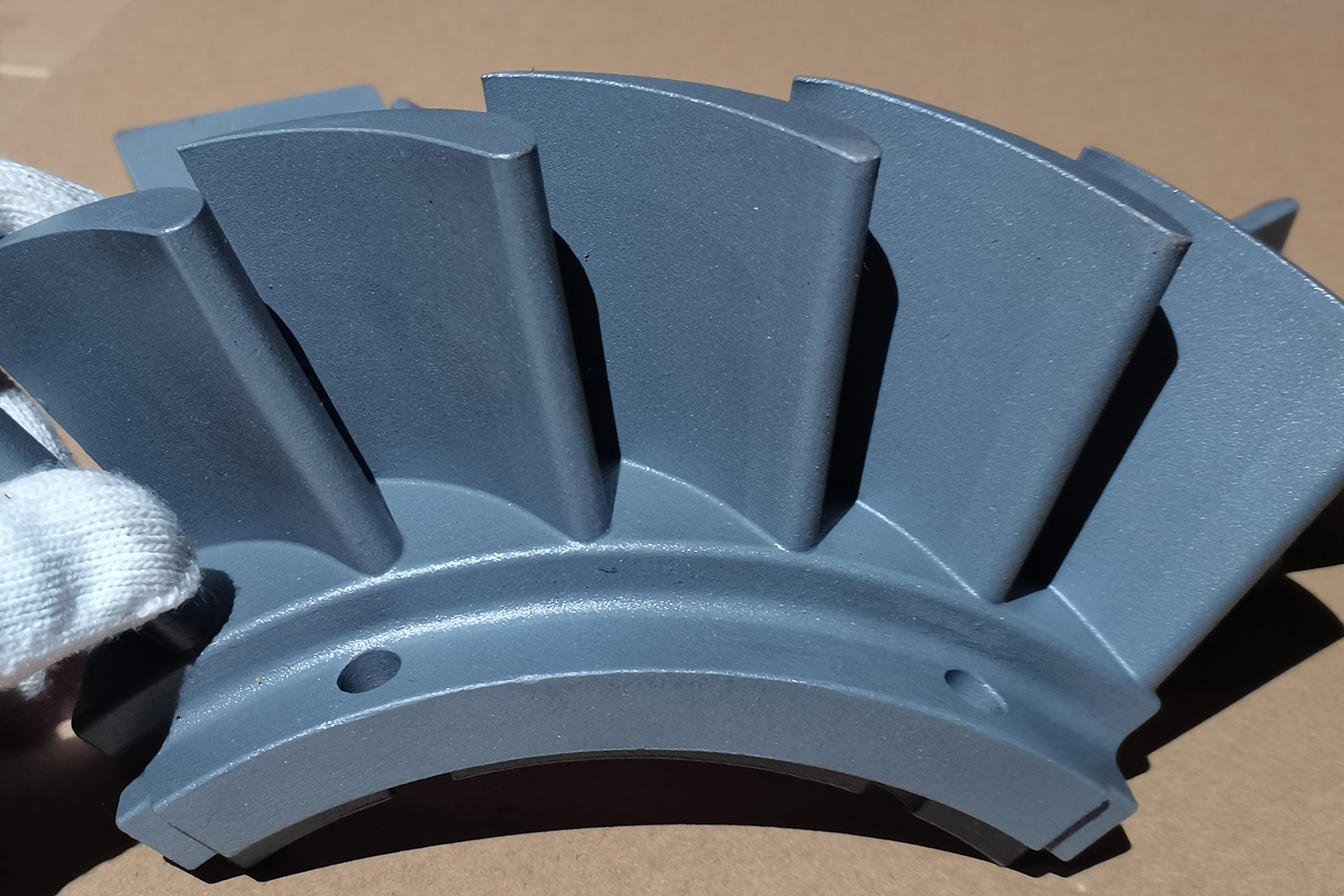

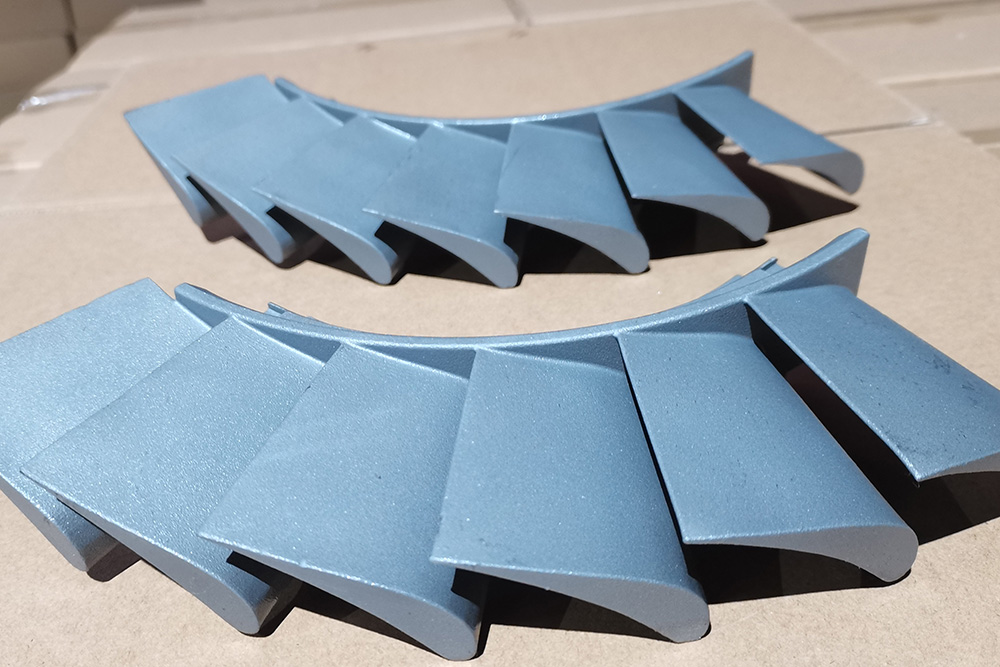

Simbi dzakadaro dzinosanganisira pasi, yepakati uye yakakwirira chromium zviri mukati. Yakaderera-chromium ferritic simbi isina tsvina ine inosvika gumi neshanu kusvika gumi neina muzana chromium, senge 00Cr12 uye 0Cr13Al muChina. American AISI 400, 405, 406MF-2. Iyi mhando yesimbi ine kuoma kwakanaka, plastiki, kutonhora deformation uye weldability. Nekuti simbi ine imwe huwandu hwechromium nealuminium, ine yakanaka oxidation kuramba uye ngura kuramba. 405 inogona kushandiswa se petroleum refining tower, tank lining, steam turbine blade, high tembiricha sulfur corrosion resistant device, etc. 400 yemidziyo yemumba nehofisi, etc. etc. Medium chromium ferritic stainless steel, chromium content i14% kusvika 19%, yakadai se1Cr17 uye 1Cr17Mo muChina. AISI 429, AISI 430, AISI 433, AISI 434, AISI 435, AISI 436, AISI 439 muUnited States. Rudzi urwu rwesimbi rune ngura iri nani uye kusagadzikana kwekuora. Basa rayo rekuomesa coefficient idiki (n≈2), uye ine yakanaka yakadzika yekudhirowa kuita, asi iyo ductility haina kunaka. AISI 430 ferritic stainless steel inoshandiswa pakushongedza kwekuvaka, kushongedza kwemotokari, midziyo yekicheni, zvinopisa gasi uye zvikamu zve nitric acid industrial equipment, etc. AISI 434 inoshandiswa pakushongedza kwekunze kwemotokari uye zvivako. 439 inoshandiswa sepombi yemagetsi emvura inopisa, marasha uye gasi pombi, nezvimwewo. High chromium ferritic simbi isina tsvina ine 19% kusvika 30% chromium, yakadai seCr18Si2 uye Cr25 kuChina, AISI 442, AISI 443 uye AISI 446 muUnited States. States. Simbi dzakadaro dzine good oxidation resistance. AISI 442 inoshandiswa nguva dzose mumhepo, tembiricha yepamusoro inosvika 1035 ° C, uye tembiricha yepamusoro yekuenderera mberi kwekushandisa i980 ° C. AISI 446 ferritic Stainless simbi ine nani oxidation kuramba.

High-purity ferritic stainless steel

Mhando iyi yesimbi ine kabhoni yakaderera zvakanyanya, nitrogen; yakakwirira chromium, molybdenum, titanium, niobium uye zvimwe zvinhu. Zvakadai seChina's 00Cr17Mo, 00Cr18Mo2, 00Cr26Mol, 00Cr30Mo2. Iyi mhando yesimbi ine yakanaka mechanicha zvinhu (kunyanya kuoma), weldability, intergranular corrosion resistance, pitting corrosion resistance, crevice corrosion resistance, uye yakanakisa kushushikana kukoromoka kukaruka kuramba. Semuyenzaniso, 18-2 ferritic stainless simbi ine yakanaka corrosion resistance munitric acid, acetic acid, NaOH, pitting corrosion resistance mu3% NaCl uye FeCl3 yakaenzana kana kudarika 18-8 austenitic stainless steel, 26CrMo simbi mune dzakawanda media Corrosion resistance. , kunyanya mu organic acids, oxidizing acids, uye alkali yakasimba. Iyo ine yakanaka pitting corrosion resistance mune yakasimba chloride medium. Hapana kushungurudza corrosion kuparuka kunoitika muchloride, hydrogen sulfide, yakawandisa sulfuric acid uye alkali yakasimba. 30Cr-2Mo ine yakakwirira kupikisa kugomba corrosion uye crevice corrosion uku uchichengetedza kusagadzikana kwemarara kuramba.

Corrosion resistance ye ferritic Stainless simbi

(1) Kuora kwakafanana.

Chromium ndicho chinhu chiri nyore kudarika. Mumamiriro ekunze, iyo iron-chromium alloy ine chromium inodarika 12% inogona kuzvifambisa. Mune oxidizing medium, iyo chromium yemukati inogona kupfuudzwa kana inopfuura 17%. Mune imwe corrosive medium, yakakwira chromium uye molybdenum, nickel, mhangura uye zvimwe zvinhu zvinogona kuwedzerwa kuti uwane yakanaka corrosion resistance.

(2) Intergranular corrosion.

Ferritic Stainless steels, senge austenitic Stainless steels, inotambura ne intergranular corrosion, asi iyo sensitization kurapa uye kupisa kupisa kudzivirira kuparara uku kwakangopesana. Ferritic Stainless simbi inokanganisa intergranular corrosion kubva kukurumidza kutonhora pamusoro pe925 ° C, uye nyika (sensitized state) inotapukirwa ne intergranular corrosion inogona kubviswa mushure menguva pfupi yekupisa pa650-815 ° C. Iyo intergranular corrosion yeferritic simbi zvakare mhedzisiro yekuderera kwechromium kunokonzerwa nekunaya kwecarbide. Naizvozvo, kudzikisa zvirimo zvekabhoni nenitrogen musimbi uye nekuwedzera zvinhu zvakaita setitanium uye niobium zvinogona kuderedza kubatwa kwe intergranular corrosion.

(3) Gomba uye ngura.

Chromium uye molybdenum ndizvo zvinonyanya kushanda zvinhu zvekuvandudza gomba uye crevice corrosion kuramba kwesimbi isina tsvina. Sezvo chromium yemukati ichiwedzera, iyo chromium yemukati mune oxide firimu inowedzera, uye kugadzikana kwemakemikari emufirimu kunowedzera. Molybdenum inoshambadzirwa pamusoro pesimbi inoshanda muchimiro cheMoO4, iyo inodzivisa kuparara kwesimbi, inosimudzira repassivation, uye inodzivirira kukanganisa kwefirimu. Naizvozvo, yakakwira chromium uye molybdenum ferritic simbi isina tsvina ine yakanakisa kupikisa kugomba uye kukoromoka kwegora.

(4) Kupokana nekusimbisa corrosion cracking.

Nekuda kwehunhu hwechimiro chesangano, ferritic Stainless simbi inoshingirira mukuora mukati mepakati apo austenitic Stainless simbi inoburitsa stress corrosion cracking.

Mechanical properties yeferritic Stainless simbi

Ferritic Stainless Simbi haigoni kusimbiswa nekurapa kwekupisa nokuti hapana shanduko yechikamu. Kazhinji, inoshandiswa mushure mekuvhara pa700-800 ° C. Nekuda kwehukuru hwakafanana hweatomu yesimbi nechromium, iyo yakasimba mhinduro yekusimbisa mhedzisiro idiki, simba regoho uye kusimba kwesimba referritic stainless simbi yakakwira zvishoma pane iyo yakaderera kabhoni simbi, uye iyo ductility yakadzikira pane iyo yakaderera kabhoni simbi. .

1) Tembiricha yekamuri brittleness yeyakajairwa ferritic Stainless simbi.

Ordinary ferritic Stainless simbi inonzwa kune notches, uye brittle transition tembiricha iri pamusoro pekamuri tembiricha kunze kweyakaderera-chromium ferritic simbi isina tsvina. Iyo yakakwirira yemukati yechromium, inokura iyo inotonhora brittleness. Uku kutonhora brittleness kune hukama neiyo interstitial zvinhu senge kabhoni uye nitrogen musimbi, uye iyo yekupedzisira-yakachena ferritic simbi ine yakaderera kabhoni yemukati mune interstitial zvinhu senge kabhoni nenitrogen, saka inogona kuwana kuoma kwakanaka, uye brittle shanduko. tembiricha inogona kudzikiswa pasi pekamuri tembiricha.

2) Kukwirisa tembiricha embrittlement yeyakajairwa ferritic simbi isina tsvina.

Yakajairika ferritic Stainless simbi inodziya kusvika pamusoro pe927 ° C uye yobva yakurumidza kutonhora kusvika kune tembiricha yekamuri, iyo plastiki uye kuoma kwakaderedzwa zvakanyanya. Uku kukwidziridzwa kwepamusoro-soro kunoenderana nekunaya nekukurumidza kwekabhoni (nitride) makomisheni pamiganhu yezviyo kana kutsemuka patembiricha ye427-927 ° C. Kuderedza kabhoni uye nitrogen zviri musimbi (uchishandisa ultra-pure tekinoroji) inogona kuvandudza zvakanyanya brittleness iyi. Mukuwedzera, kana iyo ferritic simbi inopisa pamusoro pe 927 ° C, huwandu hwezviyo huchave hwakaoma, uye zviyo zvakakoshwa zvichashatisa plastiki uye kuoma kwesimbi.

3) Kuumbwa kwe σ-phase.

Zvinoenderana neiyo iron-chromium phase diagraph, kana yachengetwa pa500-800 ° C, alloy ine 40% -50% chromium ichaita chimwe chikamu σ, uye alloy ine isingasviki 20% kana kupfuura 70% chromium ichaumba. an α+σ dual-phase chimiro. Kuumbwa kwe σ-phase kuchaderedza zvakanyanya ductility uye kuoma kwesimbi. Naizvozvo, ferritic Stainless simbi haifanirwe kushandiswa kwenguva yakareba pa500-800 ° C.

4) Brittleness pa475°C.

High chromium (> 15%) ferritic simbi ichave yakanyungudutswa zvakasimba kana ichichengetwa pa400-500 °C. Rudzi urwu rwekusimudzira runotora nguva ipfupi pane kunaya kwe σ chikamu. Semuyenzaniso, kana 0.080C-0.4Si-16.9Cr ferritic Stainless simbi inochengetwa pa450°C kwemaawa mana, kuoma kwetembiricha yemumba kunoda kudonha kusvika zero. Dhigirii re embrittlement rinowedzera nekuwedzera kwemukati mechromium, asi kuomarara kunogona kudzoserwa mushure mekurapwa pamusoro pe600 ° C. Embrittlement pa475 ° C imhedzisiro yekunaya kwechromium-rich alpha phase. Simbi yakadai haifanirwe kudziyisa pedyo ne475°C.

Nguva yekutumira: May-02-2023