Iyo yekupisa kurapwa kwesimbi castings yakavakirwa paFe-Fe3C chikamu dhayagiramu yekudzora iyo microstructure yesimbi castings kuti iwane kuita kunodiwa. Kupisa kupisa ndeimwe yenzira dzakakosha mukugadzirwa kwesimbi castings. Unhu uye mhedzisiro yekurapa kwekupisa kwakabatana zvakananga nekuita kwekupedzisira kwesimbi castings.

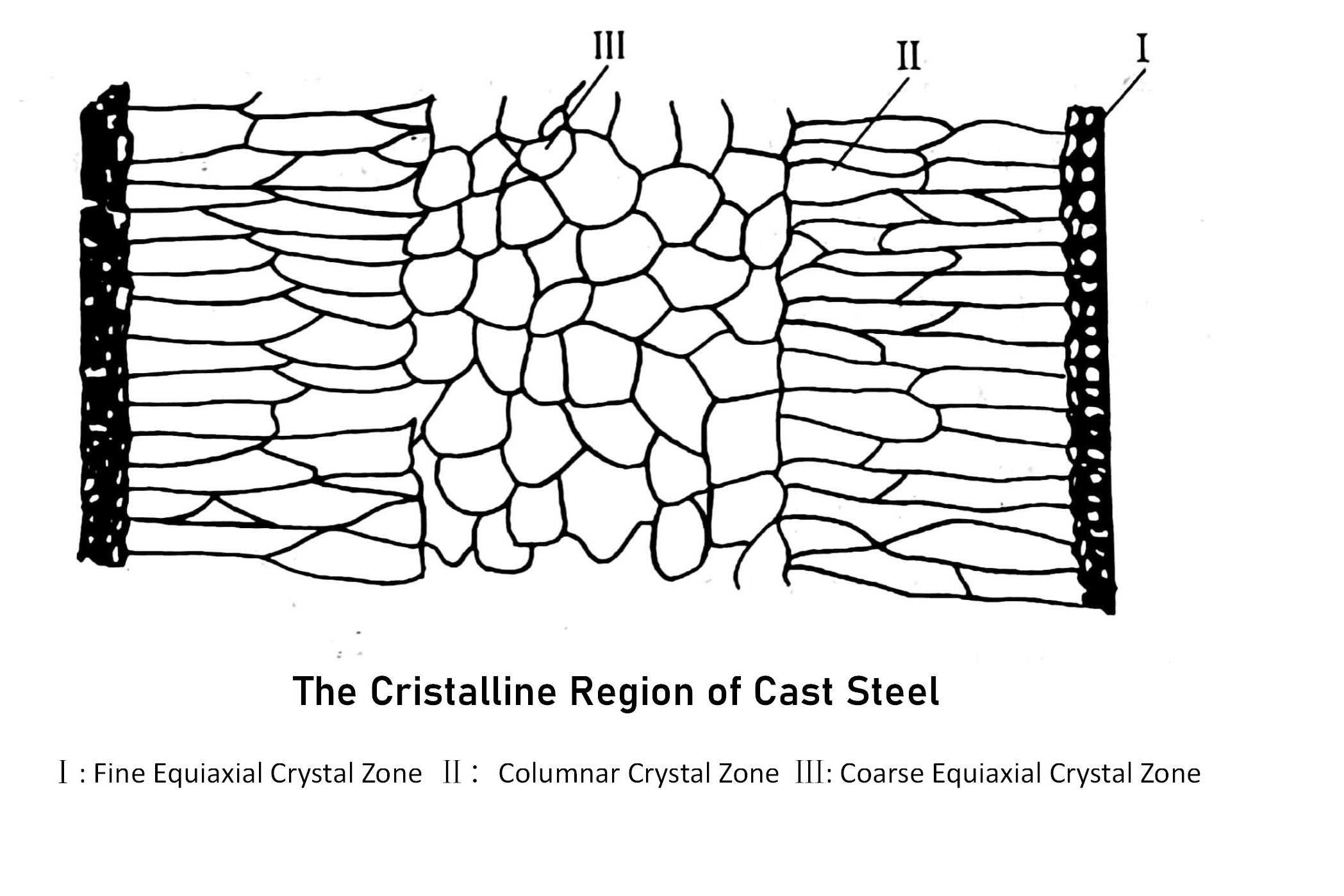

Iyo as-cast chimiro chesimbi castings zvinoenderana nemakemikari kuumbwa uye kusimba maitiro. Kazhinji, kune zvakakomba dendrite segregation, isina kuenzana chimiro uye coarse zviyo. Naizvozvo, simbi yekukanda kazhinji inoda kurapwa kupisa kuti ibvise kana kuderedza kukanganiswa kwematambudziko ari pamusoro, kuitira kuti uvandudze mashandiro emagetsi esimbi castings. Pamusoro pezvo, nekuda kwekusiyana kwechimiro uye kukora kwemadziro kwesimbi yekukanda, zvikamu zvakasiyana-siyana zvekukandira zvakafanana zvine maitiro ehurongwa akasiyana uye zvinoburitsa kushushikana kwakanyanya kwemukati. Naizvozvo, simbi castings (kunyanya alloy simbi castings) kazhinji kuendeswa munzvimbo inopisa-yakagadziriswa.

1. Hunhu hweKupisa Kurapa kweSimbi Castings

1) Muchigadziro che-as-cast of simbi castings, pane zvinowanzoita coarse dendrites uye segregation. Munguva yekupisa kwekupisa, nguva yekupisa inofanira kunge yakakwirira kudarika iyo yezvikamu zvesimbi zvekugadzira zvakafanana. Panguva imwecheteyo, nguva yekubata ye austenitization inoda kuwedzerwa zvakakodzera.

2) Nekuda kwekusarura kwakakomba kweiyo as-cast chimiro cheimwe alloy simbi castings, kuitira kuti ibvise pesvedzero yayo pane ekupedzisira maitiro ekukanda, matanho anofanirwa kutorwa kuti homogenize panguva yekupisa kurapwa.

3) Zvekukanda simbi zvine maumbirwo akaomarara uye misiyano mikuru yemadziro emadziro, michinjikwa-chikamu mhedzisiro uye kukanda kushushikana zvinhu zvinofanirwa kutariswa panguva yekupisa kupisa.

4) Kana kupisa kurapwa kunoitwa pasimbi castings, inofanira kuva inonzwisisika zvichienderana nemaitiro ayo ekugadzirisa uye edza kudzivisa deformation ye castings.

2. Izvo Zvikuru Zviitiko zveKupisa Kurapa kweSimbi Castings

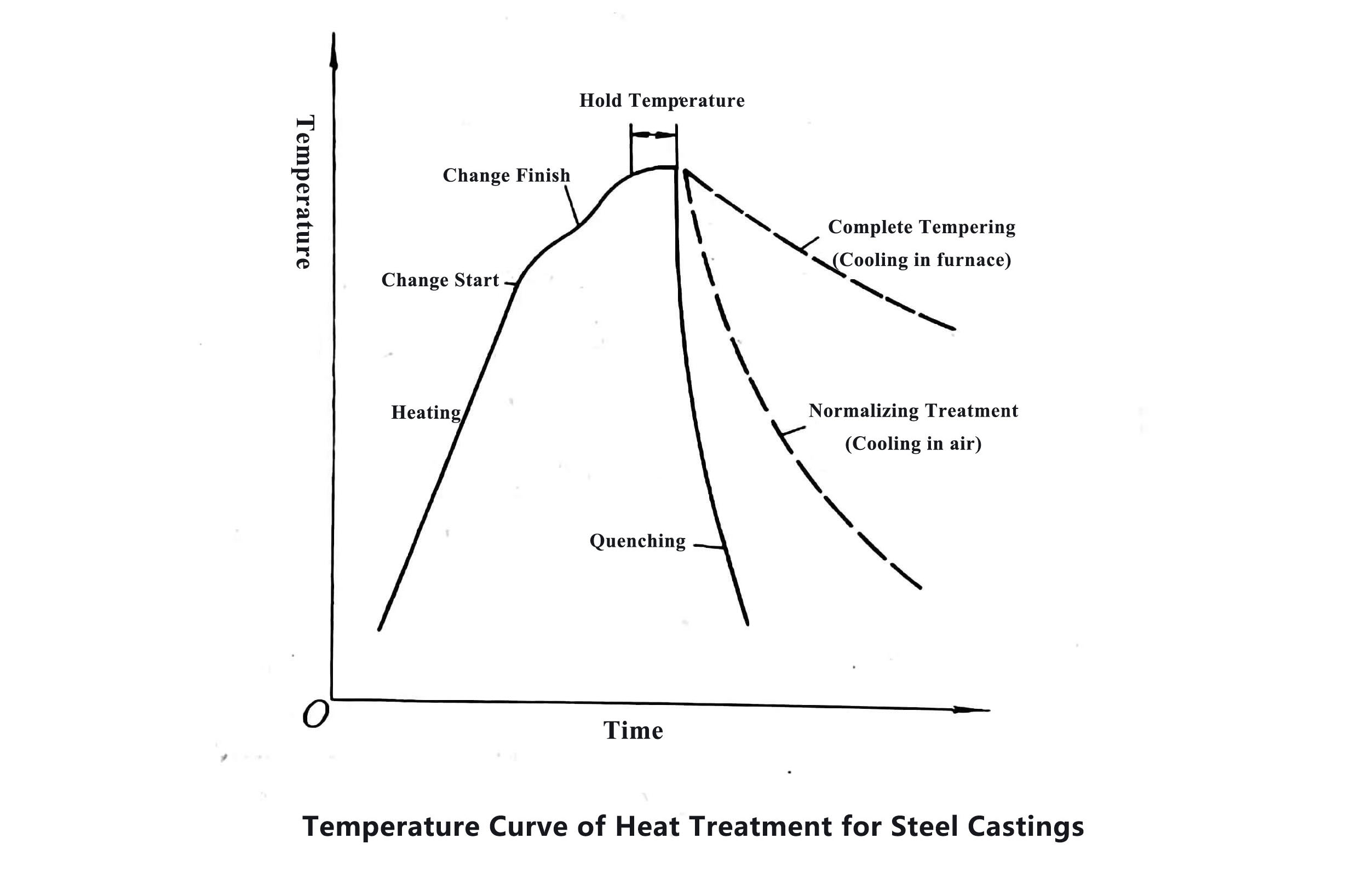

Kupisa kwekupisa kwesimbi castings kunosanganisira matanho matatu: kupisa, kuchengetedza kupisa, uye kutonhora. Kutemerwa kwemaitiro maparameter kunofanirwa kuve kwakavakirwa pachinangwa chekuona mhando yechigadzirwa uye mari yekuchengetedza.

1) Kupisa

Kupisa ndiyo inonyanya kushandisa simba muhutano hwekupisa. Iyo huru tekinoroji paramita yekudziya maitiro ndeyekusarudza yakakodzera kupisa nzira, kupisa kumhanya uye yekuchaja nzira.

(1) Nzira yekupisa. Nzira dzekudziya dzekukandira simbi dzinonyanya zvinosanganisira kupisa kunopenya, kupisa munyu yekugezera uye kupisa induction. Nheyo yekusarudza yekudziya nzira inokurumidza uye yunifomu, iri nyore kudzora, kushanda kwakanyanya uye kudhura kwakaderera. Paunenge uchidziya, iyo inowanikwa inowanzo tarisa kukura kwechimiro, makemikari kuumbwa, kupisa kupisa maitiro uye hunhu hunodiwa hwekukanda.

(2) Kukurumidza kupisa. Kune general simbi castings, iyo yekupisa yekumhanyisa inogona kunge isina kuganhurirwa, uye iyo yakanyanya simba rechoto rinoshandiswa kupisa. Iko kushandiswa kwekuchaja kwechoto inopisa kunogona kupfupisa zvakanyanya nguva yekudziya uye kutenderera kwekugadzira. Muchokwadi, pasi pemamiriro ekukurumidza kupisa, hapana pachena tembiricha hysteresis pakati pepamusoro pekukanda uye yakakosha. Kudziisa zvishoma nezvishoma kunokonzeresa kuderedzwa kwekugadzira kushanda zvakanaka, kuwedzera kushandiswa kwesimba, uye yakakomba oxidation uye decarburization pamusoro pekukanda. Nekudaro, kune mamwe ma castings ane akaomesesa maumbirwo uye zvimiro, akakura emadziro makobvu, uye hukuru hwekupisa kwekushisa panguva yekudziya, kumhanya kwekupisa kunofanirwa kudzorwa. Kazhinji, kupisa kwakadzika uye kunonoka kupisa (pasi pe600 ° C) kana kugara kune yakaderera kana yepakati tembiricha inogona kushandiswa, uyezve kupisa nekukurumidza kunogona kushandiswa munzvimbo dzakanyanya kupisa.

(3) Kurodha nzira. Nheyo yekuti simbi yekukanda inofanira kuiswa muchoto ndeyekushandisa zvizere nzvimbo inobudirira, kuve nechokwadi chekupisa yunifomu uye kuisa ma castings kuti akanganisa.

2) Insulation

Iyo tembiricha yekubata ye austenitization yesimbi castings inofanirwa kusarudzwa zvinoenderana nekemikari inoumbwa yesimbi yakakandwa uye inodiwa zvivakwa. Iyo tembiricha yekubata inowanzokwira zvishoma (inenge 20 ° C) pane yekuumba simbi zvikamu zvezvakafanana. Kune eutectoid simbi castings, inofanirwa kuve nechokwadi kuti carbides inogona kukurumidza kuiswa mu austenite, uye kuti austenite inogona kuchengetedza zviyo zvakanaka.

Zvinhu zviviri zvinofanirwa kutariswa nekuda kwekupisa kwekuchengetedza nguva yekukanda simbi: chinhu chekutanga ndechekuita tembiricha yekukanda pamusoro uye yepakati yunifomu, uye chechipiri chinhu ndechekuvimbisa kufanana kwechimiro. Nokudaro, nguva yekubata inonyanya kuenderana nekupisa kwekushisa kwekukanda, rusvingo rwemadziro echikamu uye alloy elements. Kazhinji kutaura, alloy simbi castings inoda nguva yakareba yekubata pane kabhoni simbi castings. Kuwanda kwemadziro ekukanda kazhinji ndiyo nheyo huru yekuverenga nguva yekubata. Kune iyo nguva yekubata yekupisa kurapwa uye kurapwa kwekuchembera, zvinhu zvakaita senge chinangwa chekurapa kupisa, kubata tembiricha uye element diffusion rate inofanirwa kutariswa.

3) Kutonhora

Iyo simbi castings inogona kutonhodzwa nekumhanya kwakasiyana mushure mekuchengetedza kupisa, kuitira kupedzisa iyo metallographic shanduko, kuwana inodiwa metallographic chimiro uye kuzadzisa yakatsanangurwa maitiro ekuita. Kazhinji kutaura, kuwedzera mwero wekutonhora kunogona kubatsira kuwana chimiro chakanaka uye kunatsa zviyo, nekudaro kuvandudza ma mechanics ekukanda. Nekudaro, kana mwero wekutonhora uchimhanya zvakanyanya, zviri nyore kukonzera kushushikana kukuru mukukanda. Izvi zvinogona kukonzera deformation kana kuputika kwecastings ine yakaoma zvimiro.

Iyo yekutonhodza yekurapa kwekupisa kwesimbi castings kazhinji inosanganisira mweya, mafuta, mvura, mvura yemunyu uye munyu wakanyungudutswa.

3. Kupisa Kurapa Nzira yeSimbi Castings

Zvinoenderana neyakasiyana nzira dzekudziya, kubata nguva uye kutonhora mamiriro, nzira dzekupisa dzesimbi castings dzinonyanya kusanganisira annealing, normalizing, quenching, tempering, solution treatment, precipitation hardness, stress relief treatment and hydrogen kubvisa kurapwa.

1) Kuwedzera.

Anealing ndeyekupisa simbi ine chimiro chinotsauka kubva kune yakaenzana kuenda kune imwe tembiricha yakafanotemerwa nemaitiro, uye wozoitonhodza zvishoma nezvishoma mushure mekuchengetedza kupisa (kazhinji kutonhora nechoto kana kuvigwa mune lime) kuwana nzira yekupisa kupisa padyo ne kuenzana mamiriro echimiro. Zvinoenderana nekuumbwa kwesimbi uye chinangwa uye zvinodikanwa zvekuvharisa, annealing inogona kukamurwa kuita annealing yakakwana, isothermal annealing, spheroidizing annealing, recrystallization annealing, kushushikana kudzikamisa uye zvichingodaro.

(1) Complete Annealing. Iyo yakajairika maitiro ekuzara annealing ndeiyi: kupisa simbi yekukanda kusvika 20 °C-30 °C pamusoro peAc3, ichiibata kwenguva yakati rebei, kuitira kuti chimiro musimbi chishandurwe zvachose kuita austenite, uyezve kutonhora zvishoma nezvishoma (kazhinji. kutonhora nechoto) pa500 ℃- 600 ℃, uye pakupedzisira yakatonhodzwa mumhepo. Izvo zvinonzi zvakakwana zvinoreva kuti chimiro chakazara che austenite chinowanikwa kana chichipisa.

Chinangwa chekupedza annealing chinonyanya kusanganisira: chekutanga ndechekuvandudza chimiro chakaoma uye chisina kuenzana chinokonzerwa nekushanda kunopisa; chechipiri ndechekuderedza kuoma kwekabhoni simbi uye alloy simbi castings pamusoro pepakati kabhoni, nokudaro vachivandudza kucheka kwavo kuita (kazhinji, Kana kuoma kweiyo workpiece iri pakati pe170 HBW-230 HBW, zviri nyore kucheka. Kana kuoma yakakwira kana yakaderera pane iyi renji, ichaita kuti kucheka kunetse); chechitatu ndechekubvisa kushushikana kwemukati kwesimbi yekukanda.

Iko kushandiswa kwemhando ye annealing yakakwana. Full annealing inonyanya kukodzera kabhoni simbi uye alloy simbi castings ine hypoeutectoid kuumbwa ine kabhoni yemukati inotangira pa0.25% kusvika 0.77%. Simbi yeHypereutectoid haifanirwe kuvharwa zvizere, nekuti kana iyo hypereutectoid simbi ichipisa kusvika pamusoro peAccm uye ichitonhora zvishoma nezvishoma, yechipiri simenti inodonha ichitevedza muganho wezviyo weaustenite muchimiro chetiweki, izvo zvinoita kuti kusimba, plastiki uye kukanganisa kusimba kwesimbi kuve kwakakosha. kuderedza.

(2) Isothermal Annealing. Isothermal annealing inoreva kupisa simbi yekukandira kusvika 20 °C - 30 °C pamusoro peAc3 (kana Ac1), mushure mekubata kwenguva yakati rebei, nekukurumidza kutonhora kusvika pakakwirira tembiricha ye subcooled austenite isothermal shanduko curve, uyezve kubata kwenguva yakati. yenguva (Pearlite transformation zone). Mushure mokunge austenite ichishandurwa kuita pearlite, inotonhora zvishoma nezvishoma.

(3) Spheroidizing Annealing. Spheroidizing annealing ndeyekupisa simbi yekukanda kune tembiricha yakakwira zvishoma kupfuura Ac1, uyezve mushure menguva refu yekuchengetedza kupisa, yechipiri simenti musimbi inoshanduka kuita granular (kana spherical) simenti, uyezve nekumhanya kunononoka Kupisa kurapwa. process yekutonhodza kusvika kukamuri tembiricha.

Chinangwa che spheroidizing annealing chinosanganisira: kuderedza kuoma; kugadzira iyo metallographic chimiro yunifomu; kuvandudza kushanda kwekucheka uye kugadzirira kudzima.

Spheroidizing annealing inonyanya kushanda kune eutectoid simbi uye hypereutectoid simbi (kabhoni yemukati inodarika 0.77%) senge kabhoni mudziyo simbi, alloy chitubu simbi, rolling inobereka simbi uye alloy chishandiso simbi.

(4) Kurerutsira kushushikana kudzikamisa uye kudzoreredza annealing. Stress relief annealing inonziwo low temperature annealing. Iro muitiro wekuti simbi inokandwa inopisa kusvika pasi peAc1 tembiricha (400 °C - 500 °C), yozochengetwa kwenguva yakati rebei, yozotonhodzwa zvishoma nezvishoma kusvika mukamuri tembiricha. Chinangwa chekugadzirisa kushungurudza annealing ndechekubvisa kushushikana kwemukati kwekukanda. Iyo metallographic chimiro chesimbi haizoshanduke panguva yekushushikana kwekunetseka annealing maitiro. Recrystallization annealing inonyanya kushandiswa kubvisa iyo yakakanganiswa chimiro chinokonzerwa nekutonhora deformation kugadzirisa uye kubvisa basa kuoma. Iyo tembiricha yekudziya yerecrystallization annealing ndeye 150 ° C - 250 ° C pamusoro peiyo tembiricha recrystallization. Recrystallization annealing inogona kuumbazve iwo akareba ekristaro tsanga kuita yunifomu equiaxed makristasi mushure mekutonhora deformation, nekudaro kubvisa mhedzisiro yekuoma kwebasa.

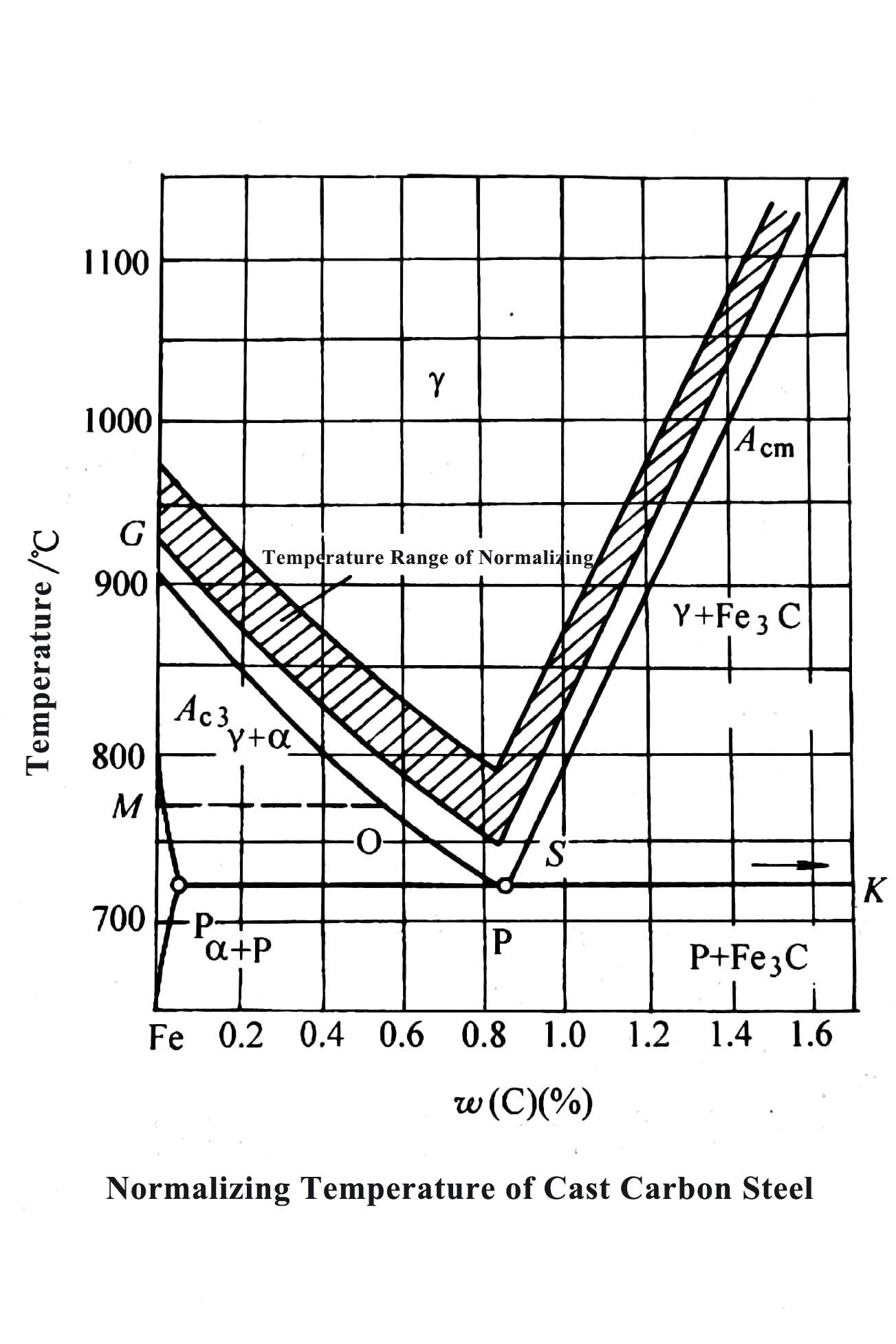

2) Normalizing

Normalizing kurapwa kwekupisa umo simbi inopisa kusvika 30 ° C - 50 ° C pamusoro peAc3 (hypoeutectoid simbi) uye Acm (hypereutectoid steel), uye mushure menguva yekuchengetedza kupisa, inotonhodzwa kusvika kune tembiricha mumhepo kana mukati. mhepo yekumanikidza. nzira. Normalizing ine kukurumidza kutonhora chiyero pane annealing, saka iyo yakajairwa dhizaini yakanaka kupfuura iyo annealed chimiro, uye kusimba kwayo nekuoma kwayo zvakare yakakwirira kupfuura iyo yeanealed chimiro. Nekuda kweiyo pfupi yekugadzira kutenderera uye yakakwirira mashandisirwo emidziyo yekushandisa, normalizing inoshandiswa zvakanyanya muakasiyana simbi castings.

Chinangwa che normalizing chakakamurwa muzvikamu zvitatu zvinotevera:

(1) Normalizing seyekupedzisira kupisa kurapwa

Kune simbi castings ine yakaderera simba zvinodiwa, normalizing inogona kushandiswa seyekupedzisira kupisa kurapwa. Normalizing inogona kunatsa zviyo, homogenize chimiro, kuderedza ferrite zviri mu hypoeutectoid simbi, kuwedzera uye kunatsiridza pearlite zvirimo, nokudaro kuvandudza simba, kuoma uye kuoma kwesimbi.

(2) Normalizing senge pre-heat kurapa

For simbi castings nezvikamu zvakakura, normalizing pamberi quenching kana quenching uye tempering (quenching uye yakakwirira tembiricha tempering) anogona kubvisa Widmanstatten chimiro uye bhendi chimiro, uye kuwana yakanaka uye yunifomu chimiro. Kune network cementite iripo mune kabhoni simbi uye alloy chishandiso simbi ine kabhoni yemukati inopfuura 0.77%, normalizing inogona kuderedza zvirimo yechipiri simenti uye kudzivirira kubva kuumba inoenderera network, kugadzirira sangano re spheroidizing annealing.

(3) Kuvandudza kucheka kushanda

Normalizing inogona kuvandudza kushanda kwekucheka kwepasi kabhoni simbi. Kuomarara kwekabhoni simbi yekukandira kwakadzikira zvakanyanya mushure mekuvhara, uye zviri nyore kunamatira kubanga panguva yekucheka, zvichikonzera kushata kwepamusoro. Kuburikidza ne normalizing kupisa kurapwa, kuoma kweyakaderera kabhoni simbi castings inogona kuwedzerwa kusvika 140 HBW - 190 HBW, iri padyo neyakakwana yekucheka kuoma, nekudaro ichivandudza kucheka kwekuita.

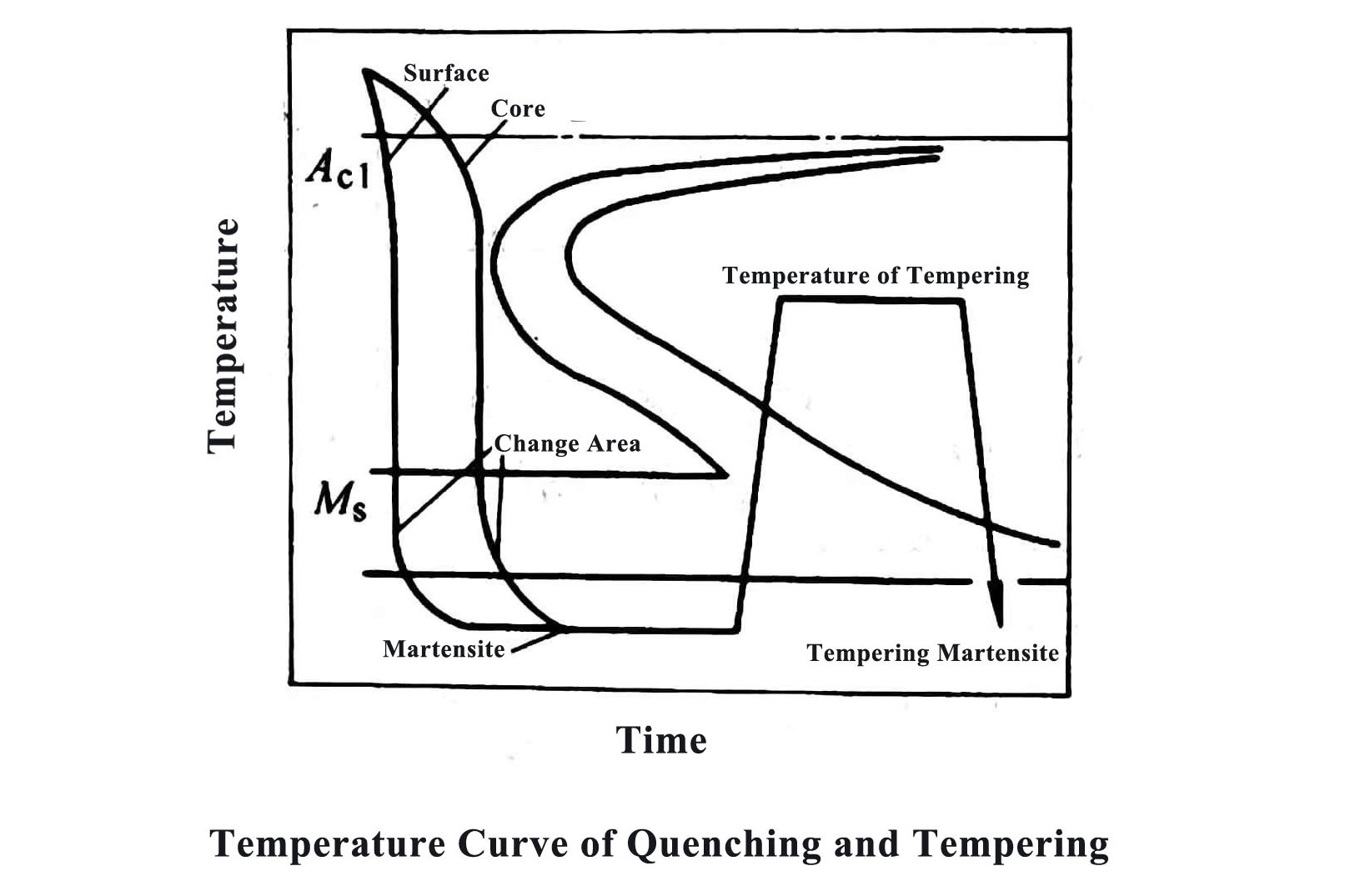

3) Kudzima

Kudzima inzira yekupisa yekupisa umo simbi inokandwa inopisa kusvika kune tembiricha iri pamusoro peAc3 kana Ac1, uye inokurumidza kutonhora mushure mekubata kwenguva yakati rebei kuwana yakazara martensitic chimiro. Iyo simbi castings inofanirwa kudzikiswa munguva mushure mekupisa zvakanyanya kubvisa kushushikana kwekudzima uye kuwana inodiwa yakazara ma mechanical properties.

(1) Kudzima tembiricha

Iyo yekudzima kupisa tembiricha ye hypoeutectoid simbi ndeye 30 ℃-50 ℃ pamusoro peAc3; kudzima tembiricha yekudziya ye eutectoid simbi uye hypereutectoid simbi iri 30 ℃-50 ℃ pamusoro peAc1. Hypoeutectoid kabhoni simbi inopisa pane yataurwa pamusoro tembiricha yekudzima kuitira kuti iwane yakanaka grained austenite, uye yakanaka martensite chimiro chinogona kuwanikwa mushure mekudzima. Iyo eutectoid simbi uye hypereutectoid simbi yakave spheroidized uye yakanyungudutswa isati yadzimwa nekudziya, saka mushure mekupisa kusvika 30 ℃-50 ℃ pamusoro peAc1 uye isina kukwana austenitized, chimiro chakaita austenite uye chikamu chisina kunyungudika chakatsetseka kupinza Carbon muviri zvidimbu. Mushure mekudzima, austenite inoshandurwa kuita martensite, uye isina kunyungudika cementite zvimedu zvinochengetwa. Pamusana pekuoma kwakakwirira kwecementite, haisi kungoderedza kuoma kwesimbi, asiwo inovandudza kupfeka kwayo. Iyo yakajairwa kudzimwa chimiro che hypereutectoid simbi yakanaka flaky martensite, uye yakanaka granular simenti uye shoma shoma yakachengetwa austenite yakagoverwa zvakaenzana pamatrix. Ichi chimiro chine simba rakakwirira uye kupfeka kuramba, asiwo kune imwe nhanho yekuoma.

(2) Kutonhora svikiro kudzima kupisa kupisa muitiro

Chinangwa chekudzima ndechekuwana martensite yakazara. Naizvozvo, kutonhora kweyero yesimbi yakakandwa panguva yekudzima kunofanirwa kunge kwakakura kudarika kutonhora kwakanyanya kwesimbi yakakandwa, zvikasadaro chimiro chemartensite uye zvimiro zvinoenderana hazvigone kuwanikwa. Nekudaro, yakawandisa mwero wekutonhora unogona kutungamira zviri nyore ku deformation kana kuputika kwekukanda. Kuti zvizadzise zvinodiwa pamusoro apa panguva imwe chete, iyo yekutonhodza yakakodzera inofanira kusarudzwa maererano neyakagadzika, kana nzira yekutonhodza yakarongwa inofanira kutorwa. Mune tembiricha ye650 ℃-400 ℃, iyo isothermal shanduko mwero we supercooled austenite yesimbi ndiyo yakakura. Naizvozvo, kana kukanda kuchidzimwa, kutonhora nekukurumidza kunofanirwa kuve nechokwadi mune ino tembiricha yemhando. Pazasi peMs point, mwero wekutonhora unofanirwa kunonoka kudzivirira deformation kana kupaza. Kudzima svikiro kazhinji kunotora mvura, aqueous solution kana mafuta. Muchikamu chekudzima kana kuomesa, midhiya inowanzoshandiswa inosanganisira mafuta anopisa, simbi yakanyungudutswa, munyu wakanyungudutswa kana alkali yakanyungudutswa.

Kutonhodza kwemvura munzvimbo yepamusoro yekushisa ye650 ℃-550 ℃ yakasimba, uye kutonhora kwemvura munzvimbo yakadzika yetembiricha ye300 ℃-200 ℃ yakasimba. Mvura inonyanya kukodzera kudzima uye kutonhodzwa kwekabhoni simbi castings ine maumbirwo akareruka uye mahombe emuchinjikwa-zvikamu. Kana ichishandiswa kudzima nekutonhodza, tembiricha yemvura kazhinji haina kupfuura 30°C. Nokudaro, inowanzogamuchirwa kusimbisa kutenderera kwemvura kuchengetedza tembiricha yemvura mukati mehuwandu hunonzwisisika. Mukuwedzera, kupisa munyu (NaCl) kana alkali (NaOH) mumvura kuchawedzera zvakanyanya kutonhora kwekugadzirisa.

Mukana mukuru weoiri senge yekutonhodza svikiro ndeyekuti kutonhora kwakadzika munzvimbo yakaderera ye300 ℃-200 ℃ yakadzikira zvakanyanya kupfuura iyo yemvura, iyo inogona kuderedza zvakanyanya kushushikana kwemukati kweiyo yakadzimwa workpiece uye kuderedza mukana we deformation. uye kuputika kwekukanda. Panguva imwecheteyo, kutonhora kwemafuta mumhando yepamusoro yekushisa kwe650 ℃-550 ℃ yakadzikira, inova zvakare kusakosha kukuru kwemafuta senge yekudzima. Kupisa kwemafuta ekudzima kunowanzo kudzorwa pa60 ℃-80 ℃. Oiri inonyanya kushandiswa kudzima simbi yealloy castings ine maumbirwo akaomarara uye kudzimwa kwekabhoni simbi castings ine madiki-muchinjiko-zvikamu uye zvakaoma maumbirwo.

Pamusoro pezvo, munyu wakanyungudutswa unowanzoshandiswa semudziyo wekudzima, unova kugeza munyu panguva ino. Iyo yekugezesa munyu inoratidzwa nepamusoro yekubikira uye kugona kwayo kutonhora kuri pakati pemvura nemafuta. Kugezesa munyu kunowanzo shandiswa kuomesera uye kudzima nhanho, pamwe nekurapa kwekukanda nemhando dzakaoma, diki diki uye yakasimba deformation zvinodiwa.

4) Kupisa

Tempering inoreva nzira yekupisa yekupisa iyo iyo inodzima kana yakajairwa simbi castings inopisa kune yakasarudzwa tembiricha yakaderera pane yakakosha point Ac1, uye mushure mekubata kwenguva yakati rebei, inotonhodzwa pamwero wakakodzera. Kupisa kupisa kurapwa kunogona kushandura iyo isina kugadzikana chimiro chakawanikwa mushure mekudzima kana normalizing kuita yakagadzikana chimiro kubvisa kushushikana uye kugadzirisa epurasitiki uye kuoma kwesimbi castings. Kazhinji, maitiro ekupisa ekudzima uye kupisa kwakanyanya kupisa kurapwa kunonzi quenching uye tempering kurapwa. Iyo yakadzimwa simbi castings inofanirwa kudzikiswa nenguva, uye yakajairwa simbi castings inofanirwa kudzikiswa kana zvichidikanwa. Kuita kwesimbi castings mushure mekupisa kunoenderana nekupisa tembiricha, nguva uye nhamba yenguva. Kuwedzera kwekushisa kwekupisa uye kuwedzera kwekubata nguva chero nguva haigone kungobvisa kudzima kushushikana kwesimbi castings, asiwo kushandura isina kugadzikana quenched martensite kuita tempered martensite, troostite kana sorbite. Simba uye kuoma kwesimbi castings kunoderedzwa, uye plastiki inovandudzwa zvakanyanya. Kune mamwe masimbi epakati alloy ane alloying zvinhu zvinoumba zvine simba carbides (senge chromium, molybdenum, vanadium uye tungsten, nezvimwewo), kuoma kunowedzera uye kuoma kunodzikira kana kupisa pa400 ℃ -500 ℃. Ichi chiitiko chinonzi chechipiri kuomesa, ndiko kuti, kuoma kwesimbi yakakandwa mumamiriro ekutsamwa kunosvika pakakwirira. Mukugadzira chaiko, yepakati alloy cast simbi ine yechipiri kuomesa maitiro inoda kudzikiswa kakawanda.

(1) Kudzikira tembiricha

Iyo tembiricha yemhando yakaderera tembiricha tempering ndeye 150 ℃-250 ℃. Kudzikira tembiricha yakadzika kunogona kuwana yakanyorovera martensite chimiro, iyo inonyanya kushandiswa kudzima yakakwira kabhoni simbi uye kudzima yakakwira alloy simbi. Tempered martensite inoreva chimiro chekriptocrystalline martensite pamwe neakanaka granular carbides. Chimiro che hypoeutectoid simbi mushure mekudzika kwekushisa kwekushisa kunopisa martensite; chimiro che hypereutectoid simbi mushure mekudzika kwekushisa kwekushisa kunopisa martensite + carbides + yakachengetwa austenite. Chinangwa chekudziya kwakadzika tembiricha ndechekuvandudza kuoma kwesimbi yakadzimwa uchichengetedza kuomarara kwakanyanya (58HRC-64HRC), simba repamusoro uye kuramba kupfeka, uku ichideredza zvakanyanya kudzikama kushushikana uye brittleness yesimbi castings.

(2) Tembiricha iri pakati nepakati

Tembiricha yekudziya yepakati tembiricha kazhinji iri pakati pe350 ℃ -500 ℃. Chimiro mushure mekupisa pane tembiricha yepakati ihombe-yakaomeswa cementite yakaparadzirwa uye yakagoverwa pane ferrite matrix, ndiko kuti, kushatirwa kwetroostite chimiro. Iyo ferrite mune yakatsamwa troostite chimiro ichiri kuchengetedza chimiro chemartensite. Kushushikana kwemukati kwesimbi yekukanda mushure mekupisa kunobviswa, uye ivo vane yakakwirira elastic muganho uye goho muganho, kusimba kwepamusoro uye kuoma, uye yakanaka plastiki uye kuoma.

(3) Kupisa kwakanyanya

Tembiricha yepamusoro yekupisa inowanzoitika 500 ° C-650 ° C, uye maitiro ekupisa anosanganisa kudzima uye kunotevera kupisa tembiricha kunowanzo kunzi quenching uye kudzikama kurapwa. Chimiro mushure mekupisa kwekushisa kwakanyanya kunopisa sorbite, kureva, yakanaka-grained cementite uye ferrite. Iyo ferrite mune yakatsamwa sorbite ndeye polygonal ferrite inopinda recrystallization. Simbi inokandwa mushure mekupisa tembiricha ine yakanaka yakazara mekiniki zvivakwa maererano nesimba, plastiki uye kuoma. Kupisa kwekushisa kwakanyanya kunoshandiswa zvakanyanya mukati mekabhoni simbi, yakaderera alloy simbi, uye akasiyana akakosha maumbirwo ezvikamu zvine masimba akaomarara.

5) Solid SolutionTreatment

Chinangwa chikuru chekugadzirisa kugadzirisa ndechekunyungudutsa carbides kana zvimwe zvikamu zvakanaya mumhinduro yakasimba kuti uwane supersaturated single-phase chimiro. Kukandwa kwe austenitic stainless simbi, austenitic manganese simbi uye kunaya kunoomesa simbi isina tsvina kunofanira kazhinji kuve yakasimba mhinduro yakagadziriswa. Kusarudzwa kwekushisa kwekugadzirisa kunoenderana nemakemikari ekugadzirwa uye chikamu diagram yesimbi yakakandwa. Tembiricha ye austenitic manganese simbi castings kazhinji 1000 ℃ - 1100 ℃; tembiricha ye austenitic chromium-nickel Stainless simbi castings kazhinji 1000 ℃-1250 ℃.

Iyo yakakwira iyo kabhoni yemukati musimbi yakakandwa uye iyo yakawanda isinganyungudika alloying zvinhu, iyo inokwirisa yayo yakasimba mhinduro tembiricha inofanira kunge iri. Pakunaya kwemvura inoomesa simbi inokandwa ine mhangura, kuomarara kwesimbi kunowedzera nekuda kwekunaya kwezvikamu zvakaoma zvemhangura munzvimbo yekukanda panguva yekutonhora. Kuti unyorove chimiro uye uvandudze mashandiro ekugadzirisa, simbi yekukanda inoda kuve yakasimba mhinduro inorapwa. Iyo yakasimba mhinduro tembiricha ndeye 900 ℃-950 ℃.

6) Kunaya Kuomesa Kurapa

Precipitation kuomesa kurapa ndiko kupararira kusimbisa kurapwa kunoitwa mukati me tempering tembiricha siyana, inozivikanwawo sekuchembera kwekugadzira. Chakakosha chekunaya kwemvura kuomesa kurapwa ndechekuti patembiricha yepamusoro, carbides, nitrides, intermetallic compounds uye mamwe asina kugadzikana epakati nhanho anonaya kubva kune supersaturated yakasimba mhinduro uye akaparadzirwa mumatrix, nekudaro ichiita iyo yakakandwa simbi yakazara Kuvandudzwa kwemichina uye kuoma.

Kupisa kwekurapa kwekukwegura kunobata zvakananga kushanda kwekupedzisira kwesimbi castings. Kana tembiricha yekuchembera yakanyanya kuderera, iyo yekunaya inoomesa chikamu inonaya zvishoma nezvishoma; kana tembiricha yekuchembera yakakwira zvakanyanya, kuunganidzwa kwechikamu chinokonzeresa kunokonzera kuwandisa, uye kuita kwakanakisa hakuzowanikwe. Naizvozvo, iyo yekutanga inofanirwa kusarudza yakakodzera tembiricha yekuchembera zvinoenderana neyakakandwa simbi giredhi uye yakatsanangurwa kuita kwesimbi yekukanda. Tembiricha yekuchembera yeaustenitic inodzivirira kupisa simbi yakakandwa kazhinji 550 ℃-850 ℃; tembiricha yekuchembera yehigh-simba kunaya inoomesa simbi yakakandwa kazhinji 500 ℃.

7) Stress Relief Treatment

Chinangwa chekushushikana kwekupisa kupisa kurapwa ndechekubvisa kukanda kushushikana, kudzima kushushikana uye kushushikana kunoumbwa nemachining, kuitira kudzikamisa saizi yekukanda. Kupisa kwekushushikana kwekunetseka kunowanzo kudziya kusvika ku100 ° C-200 ° C pasi peAc1, yozochengetwa kwenguva yakati, uye pakupedzisira yakatonhodzwa nechoto. Chimiro chekukanda simbi haina kuchinja panguva yekushungurudzika kwekunetseka. Carbon steel castings, low-alloy steel castings uye yakakwirira-alloy simbi castings zvese zvinogona kuiswa pasi pekunetseka kwekunetseka kurapwa.

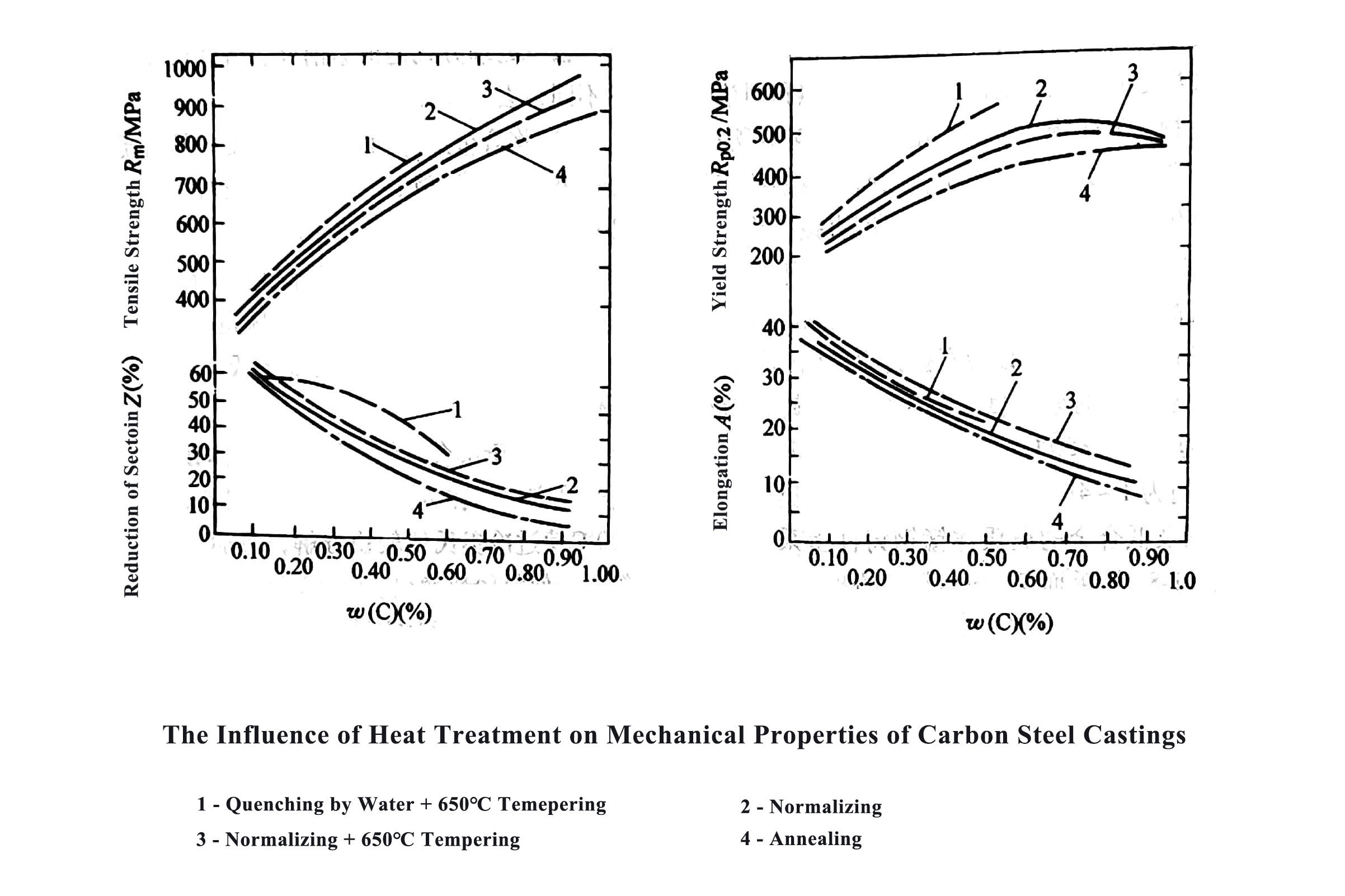

4. Mhedzisiro yeKupisa Kurapa paZvinhu zveSimbi Castings

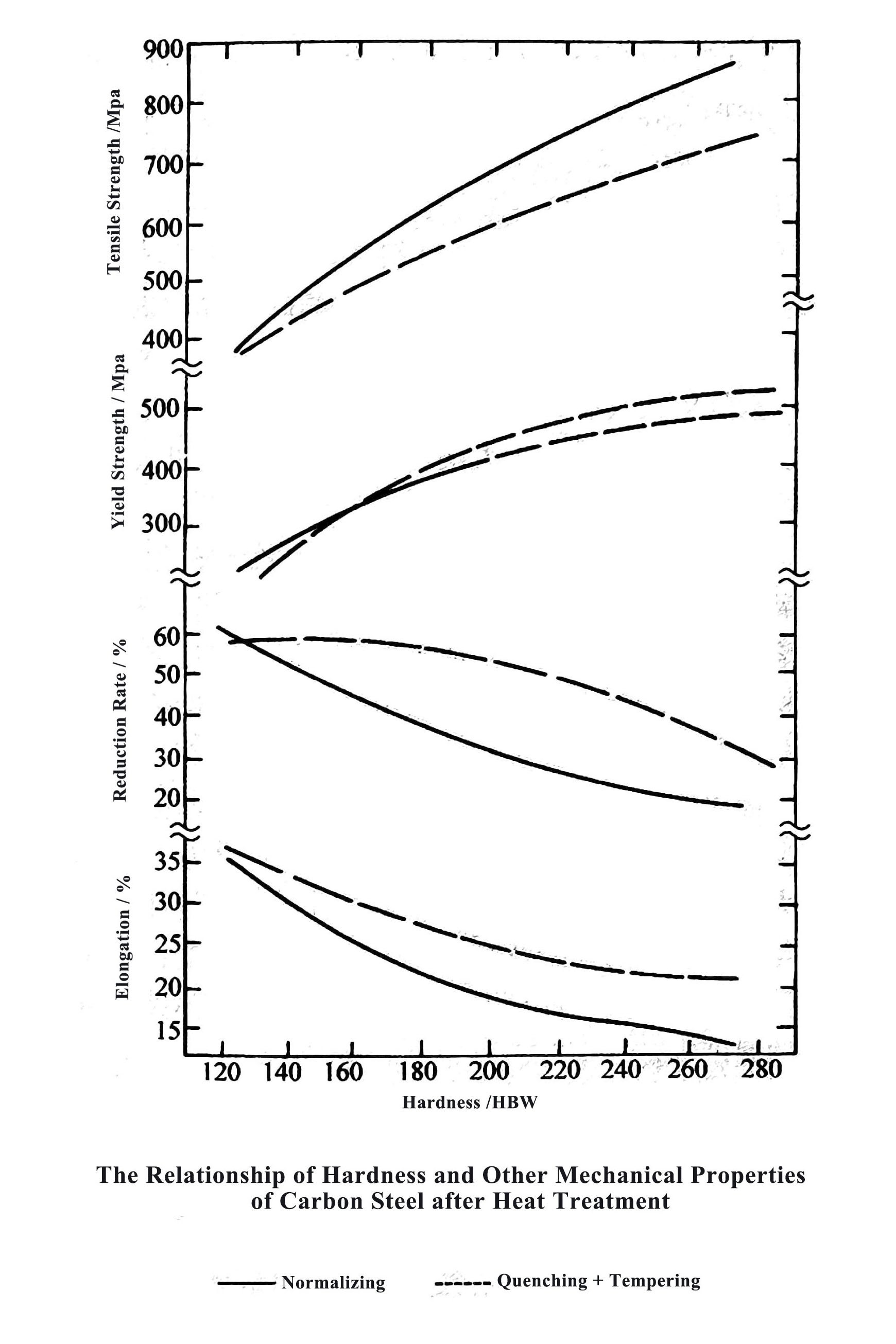

Pamusoro pekuita kwesimbi castings zvichienderana nekuumbwa kwemakemikari uye maitiro ekukanda, nzira dzakasiyana dzekupisa kupisa dzinogona kushandiswawo kuita kuti ive yakanakisa yakazara ma mechanical properties. Chinangwa chikuru chekugadzirisa kupisa ndechekuvandudza hutano hwekukanda, kuderedza uremu hwemakanda, kuwedzera hupenyu hwebasa uye kuderedza mari. Kurapa kwekupisa inzira yakakosha yekuvandudza ma mechanical properties of castings; iyo mechanical properties ye castings chiratidzo chakakosha chekutonga mhedzisiro yekupisa kurapwa. Mukuwedzera kune zvinotevera zvivakwa, iyo foundry inofanirawo kufunga nezvezvinhu zvakadai sekugadzirisa maitiro, kucheka kushanda uye kushandiswa kwezvinodiwa zvekukanda kana kupisa-kupisa simbi castings.

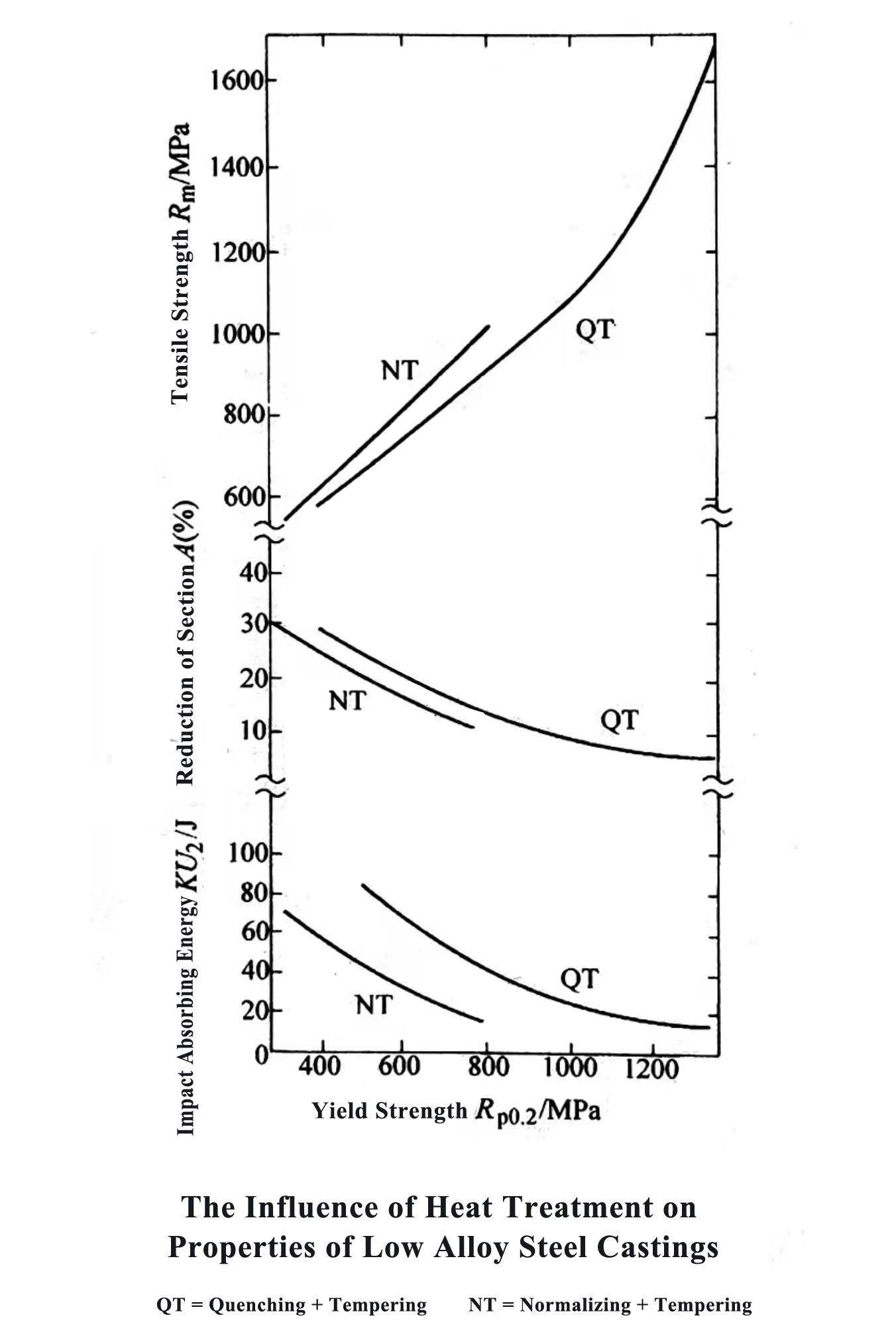

1) Kufurira kweKupisa Kurapa pane Simba reCastings

Pasi pemamiriro ekuumbwa kwesimbi yakafanana, kusimba kwesimbi yesimbi mushure mekusiyana-siyana kwekugadzirisa kupisa kune tsika yekuwedzera. Kazhinji, kusimba kwekabhoni simbi castings uye yakaderera alloy simbi castings inogona kusvika 414 Mpa-1724 MPa mushure mekupisa kurapwa.

2) Mhedzisiro yeKupisa Kurapa paPlastiki yeSimbi Castings

Iyo as-cast chimiro chesimbi castings yakaoma uye plastiki yakaderera. Mushure mekupisa kupisa, microstructure yayo uye plasticity ichavandudzwa maererano. Kunyanya iyo plasticity yesimbi castings mushure mekudzima uye kupisa kurapwa (kudzima + kupisa kwakanyanya kupisa) kuchave kwakanyanya kuvandudzwa.

3) Kuoma kweSimbi Castings

Iyo toughness index yesimbi castings inowanzoongororwa nemhedzisiro bvunzo. Sezvo kusimba uye kuomarara kwesimbi castings ari maviri ezviratidziro zvinopokana, iyo foundry inofanirwa kuita fungidziro dzakadzama kuti isarudze yakakodzera kupisa kupisa maitiro kuitira kuti iwane yakazara ma mechanical zvinhu zvinodiwa nevatengi.

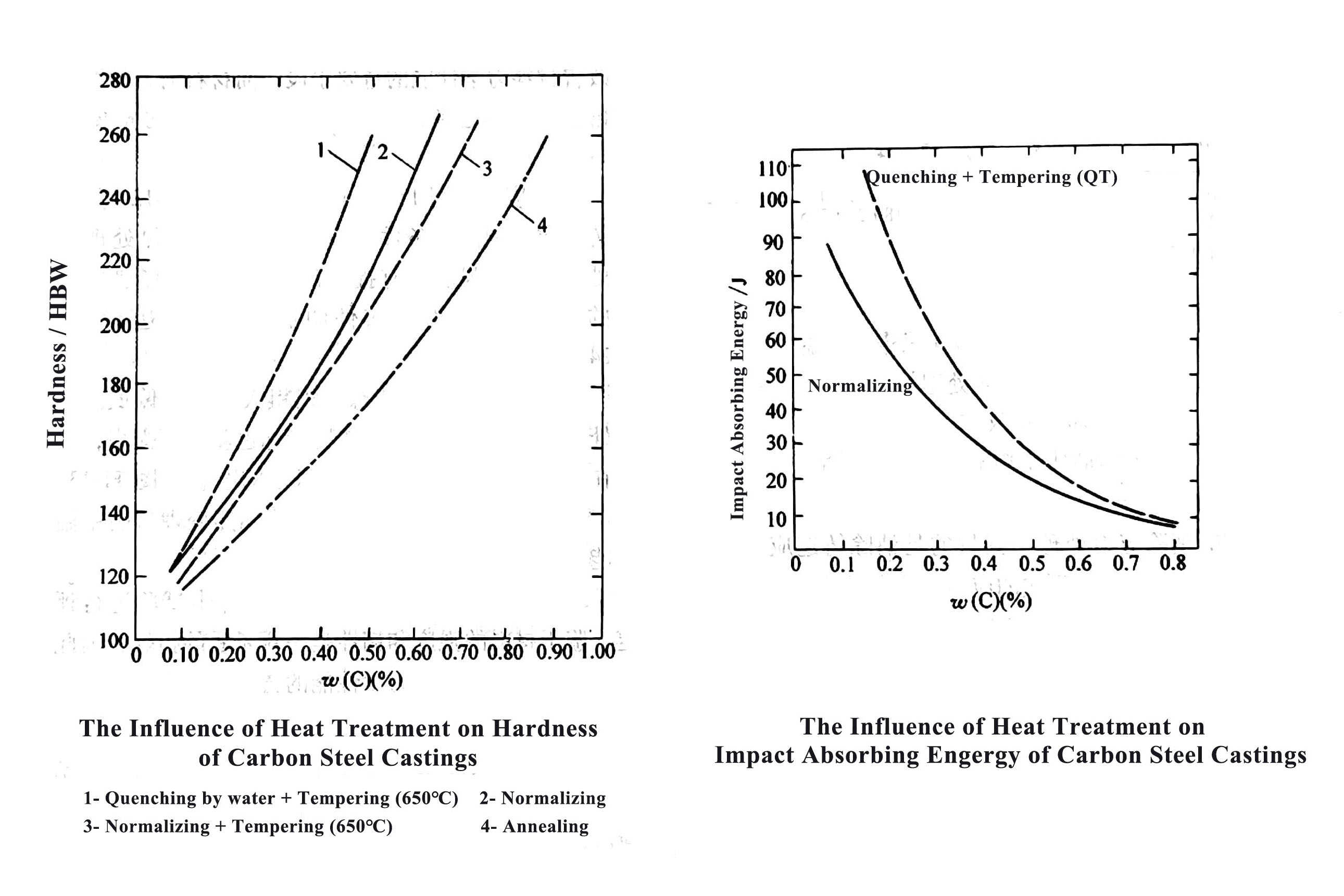

4) Mhedzisiro yeKupisa Kurapa pane Kuoma kweCastings

Kana kuoma kwesimbi yakakandwa kwakafanana, kuoma kwesimbi yakakandwa mushure mekupisa kupisa kunogona kuratidza kusimba kwesimbi yakakandwa. Nokudaro, kuoma kunogona kushandiswa se intuitive index yekufungidzira kushanda kwesimbi yakakandwa mushure mekupisa kupisa. Kazhinji kutaura, kuoma kwekabhoni simbi castings kunogona kusvika 120 HBW - 280 HBW mushure mekupisa kupisa.

Nguva yekutumira: Jul-12-2021