Wear-resistant (kana abrasion-resistant) simbi yakakandwa (cast steel) zvinoreva simbi yakakandwa ine kusakara kwakanaka. Zvinoenderana nemakemikari ekuumbwa, yakakamurwa kuita isiri-alloy, yakaderera-alloy uye alloy kupfeka-resistant simbi yakakandwa. Kune mhando dzakawanda dzesimbi isingachinjiki, iyo inogona kukamurwa kuita yakakwirira-manganese simbi, yepakati uye yakaderera-alloy kupfeka-resistant simbi, chromium-molybdenum-silicon-manganese simbi, cavitation-resistant simbi, kupfeka-resistant simbi, uye inokosha kupfeka-resistant simbi. Mamwe masimbi akajairwa alloy akadai sesimbi isina simbi, inotakura simbi, alloy chishandiso simbi uye alloy chimiro chesimbi anoshandiswawo sesimbi isingapfekere pasi pemamiriro chaiwo.

Masimbi epakati uye akaderera-alloy anodzivirira anowanzo aine zvinhu zvemakemikari zvakaita sesilicon, manganese, chromium, molybdenum, vanadium, tungsten, nickel, titanium, boron, mhangura, rare earths, etc. Matani ebhora rakakura uye repakati nepakati. Zvigayo muUnited States zvinogadzirwa nechromium-molybdenum-silico-manganese kana chromium-molybdenum simbi. Mazhinji emabhora ekukuya muUnited States akagadzirwa nepakati uye yakakwira kabhoni chromium molybdenum simbi. Kune maworkpiece anoshanda pasi petembiricha yakakwira (semuenzaniso, 200~500℃) abrasive kupfeka mamiriro kana iyo nzvimbo inoiswa kune yakanyanya tembiricha nekuda kwekupisa kwemhepo, alloys akadai chromium molybdenum vanadium, chromium molybdenum vanadium nickel kana chromium vanadium molybde inogona kushandiswa.

Abrasion (Abrasion) chiitiko chekuti zvinhu zviri pamusoro pebasa rechinhu zvinoramba zvichiparadzwa kana kurasika mukufamba kwakasiyana. Yakakamurwa nemaitiro ekupfeka, kupfeka kunogona kukamurwa kuita abrasive kupfeka, adhesive kupfeka, corrosion kupfeka, erosion kupfeka, kubata kuneta kupfeka, kukanganisa kupfeka, fretting kupfeka uye mamwe mapoka. Mundima yeindasitiri, abrasive kupfeka uye adhesive kupfeka account yechikamu chikuru chekutadza kupfeka kweworkpiece, uye kupfeka kutadza nzira dzakadai sekukukurwa, ngura, kuneta, uye kunetseka zvinowanzoitika mukushanda kwezvimwe zvakakosha zvikamu, saka vari kuwedzera. uye kunyanya kutarisa. Pasi pemamiriro ekushanda, maitiro akawanda ekupfeka anowanzoonekwa panguva imwe chete kana imwe pashure peimwe, uye kupindirana kwekukundikana kwekupfeka kunotora fomu yakaoma. Kusarudza rudzi rwekupfeka kukundikana kweworkpiece ndiyo nheyo yekusarudza kunonzwisisika kana kukura kwesimbi inodzivirira kupfeka.

Mukuwedzera, kupfeka kwezvikamu uye zvikamu idambudziko reinjiniya system. Pane zvinhu zvakawanda zvinokanganisa kupfeka, zvinosanganisira mamiriro ekushanda (mutoro, kumhanya, mafambiro), mamiriro ekuzora, mamiriro ekunze (hunyoro, tembiricha, yakatenderedza midhiya, nezvimwewo), uye zvinhu zvinhu (Kuumbwa, sangano, mechanical zvivakwa), pamusoro. kunaka uye zvemuviri uye zvemakemikari zvimiro zvezvikamu. Shanduko mune chimwe nechimwe chezvinhu izvi zvinogona kushandura huwandu hwekupfeka uye kunyange kushandura nzira yekupfeka. Zvinogona kuonekwa kuti chinhu chekushandisa ndicho chimwe chezvikonzero zvinokanganisa kupfeka kwebasa rekushanda. Kuti uvandudze kupikisa kwekupfeka kwezvikamu zvesimbi, zvinodikanwa kutanga nekukakavadzana uye kupfeka system pasi pemamiriro chaiwo kuti uwane mhedzisiro yaunoda.

1. Solution Heat Treatment (Mvura Toughening Treatment) ye Wear-Resistant High Manganese Steel Castings

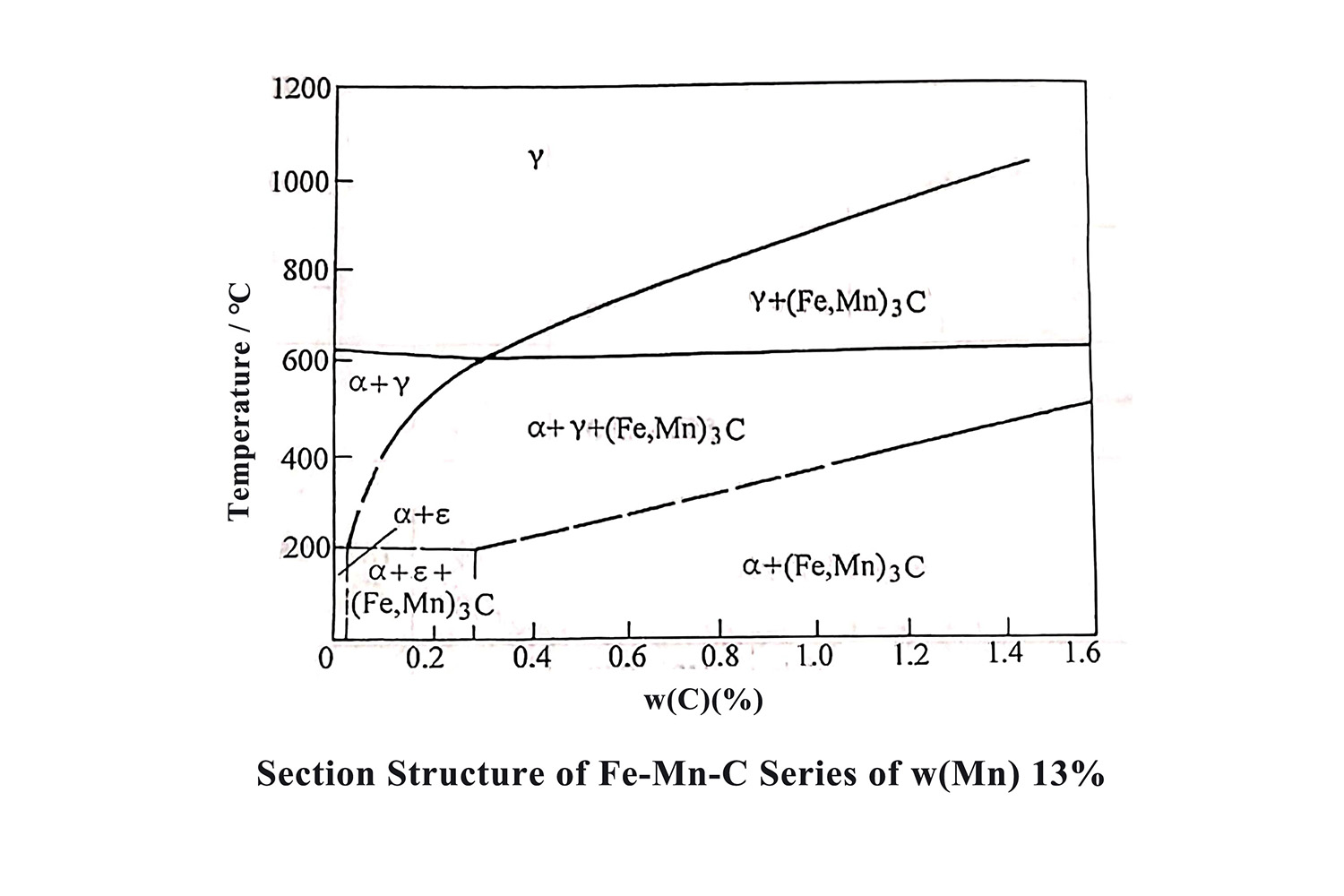

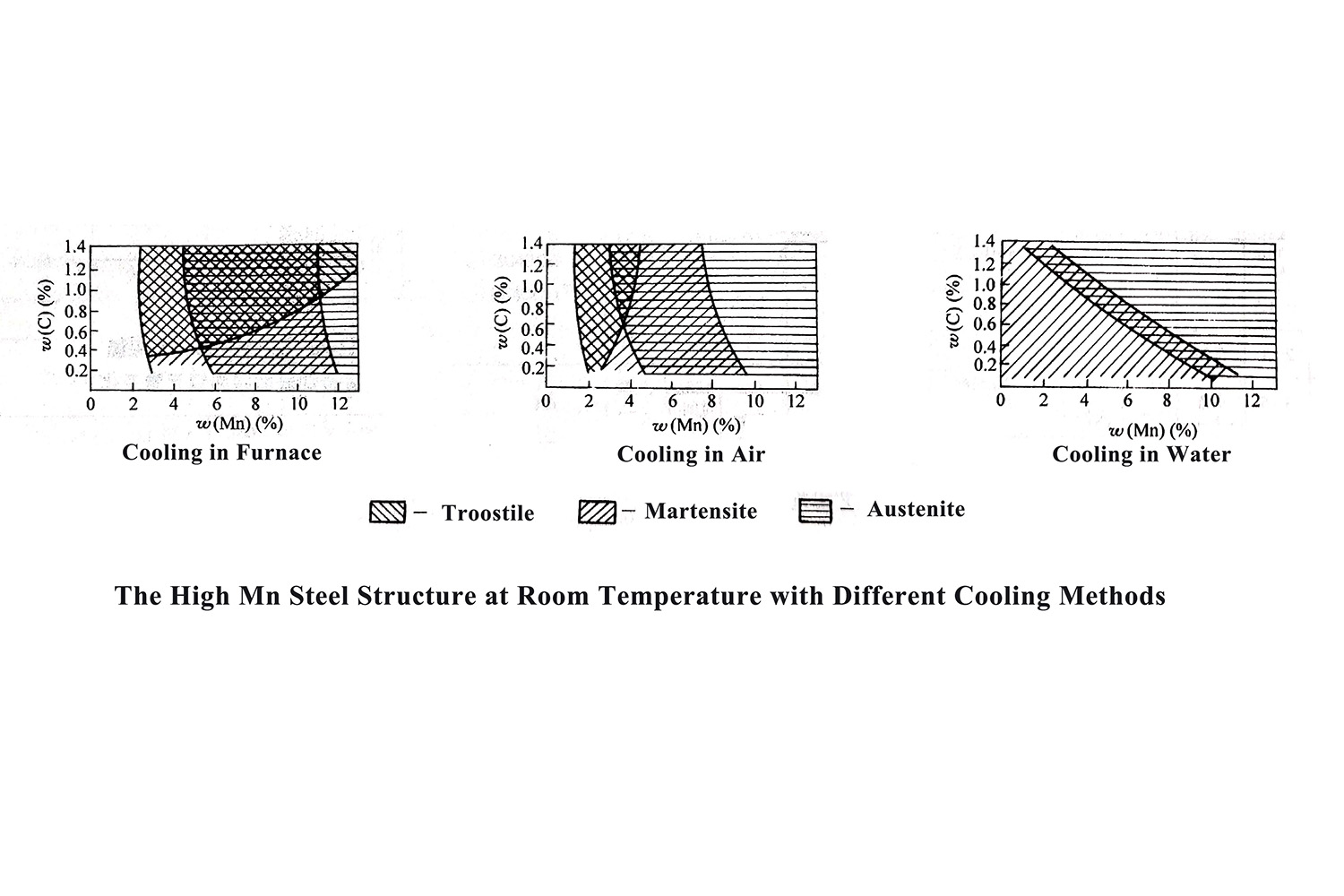

Kune huwandu hukuru hwema carbides anonaya mune se-akakanda chimiro chekupfeka-inodzivirira yakakwirira-manganese simbi. Aya carbides anozodzikisa kuoma kwekukanda uye kuita kuti zvive nyore kuputsika panguva yekushandiswa. Chinangwa chikuru chekugadzirisa kupisa kwekupisa kwepamusoro manganese simbi castings ndeyekubvisa carbides mu as-cast structure uye pamiganhu yezviyo kuti uwane imwe-phase austenite chimiro. Izvi zvinogona kuvandudza kusimba uye kuomarara kwesimbi yakakwira manganese, kuitira kuti manganese esimbi akakwira anokodzera kuwanda kweminda.

Mushonga wekupisa kupisa kwekupfeka-resistant high-manganese simbi castings inogona kukamurwa kuita nhanho dzinoverengeka: kudziyisa castings kusvika pamusoro pe1040 ° C uye kuibata kwenguva yakakodzera, kuitira kuti macarbides arimo anyungudiswe zvachose mune imwe-phase austenite. ; wobva wakurumidza kutonhora , Wana austenite yakasimba mhinduro chimiro. Uyu mushonga wekugadzirisa unonziwo water toughening treatment.

(1) Tembiricha mvura toughening kurapwa

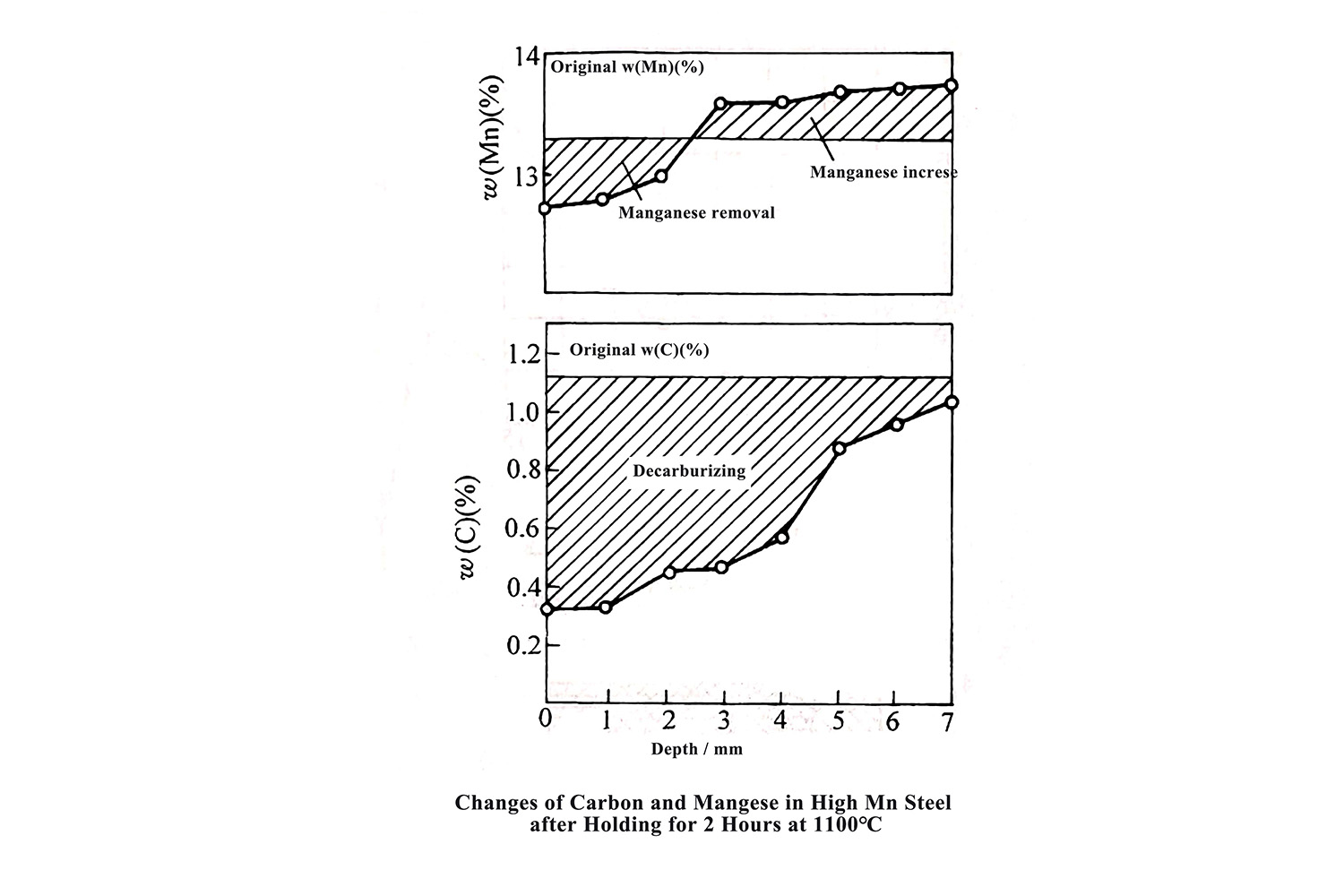

Kuoma kwemvura tembiricha kunoenderana nekemikari yesimbi yakakwira manganese, kazhinji 1050 ℃-1100 ℃. Yakakwira manganese simbi ine yakakwira kabhoni yemukati kana yakakwira alloy yemukati (yakadai seZG120Mn13Cr2 simbi uye ZG120Mn17 simbi) inofanira kutora muganho wepamusoro wekuoma kwemvura tembiricha. Nekudaro, tembiricha yakanyanyisa kuomarara kwemvura inokonzeresa decarburization pamusoro pekukanda uye kukurumidza kukura kweiyo yakakwira manganese simbi tsanga, izvo zvinokanganisa kushanda kweyakakwira manganese simbi.

(2) Heating mwero wemvura toughening kurapwa

Iyo yekupisa conductivity yemanganese simbi yakaipisisa kupfuura iyo yekabhoni simbi yakawanda. High-manganese simbi castings ine kushushikana kwakanyanya uye iri nyore kutsemuka kana ichipisa, saka chiyero chekupisa chinofanira kutariswa zvinoenderana nemadziro emadziro uye chimiro chekukanda. Kazhinji kutaura, ma castings ane madiki emadziro ukobvu uye nyore chimiro anogona kudziyisa nekukurumidza chiyero; castings ane hombe madziro ukobvu uye yakaoma chimiro anofanira kudziyisa zvishoma nezvishoma. Mune chaiyo kupisa kupisa maitiro, kuitira kuderedza deformation kana kuputika kwekukanda panguva yekupisa, inowanzo kupiswa kusvika 650 ℃ kuchengetedza kusiyana kwekushisa pakati pemukati nekunze kwekukanda kuderedzwa, uye tembiricha mukati. choto iri yunifomu, uye ipapo nokukurumidza kusimuka kumvura kuoma tembiricha.

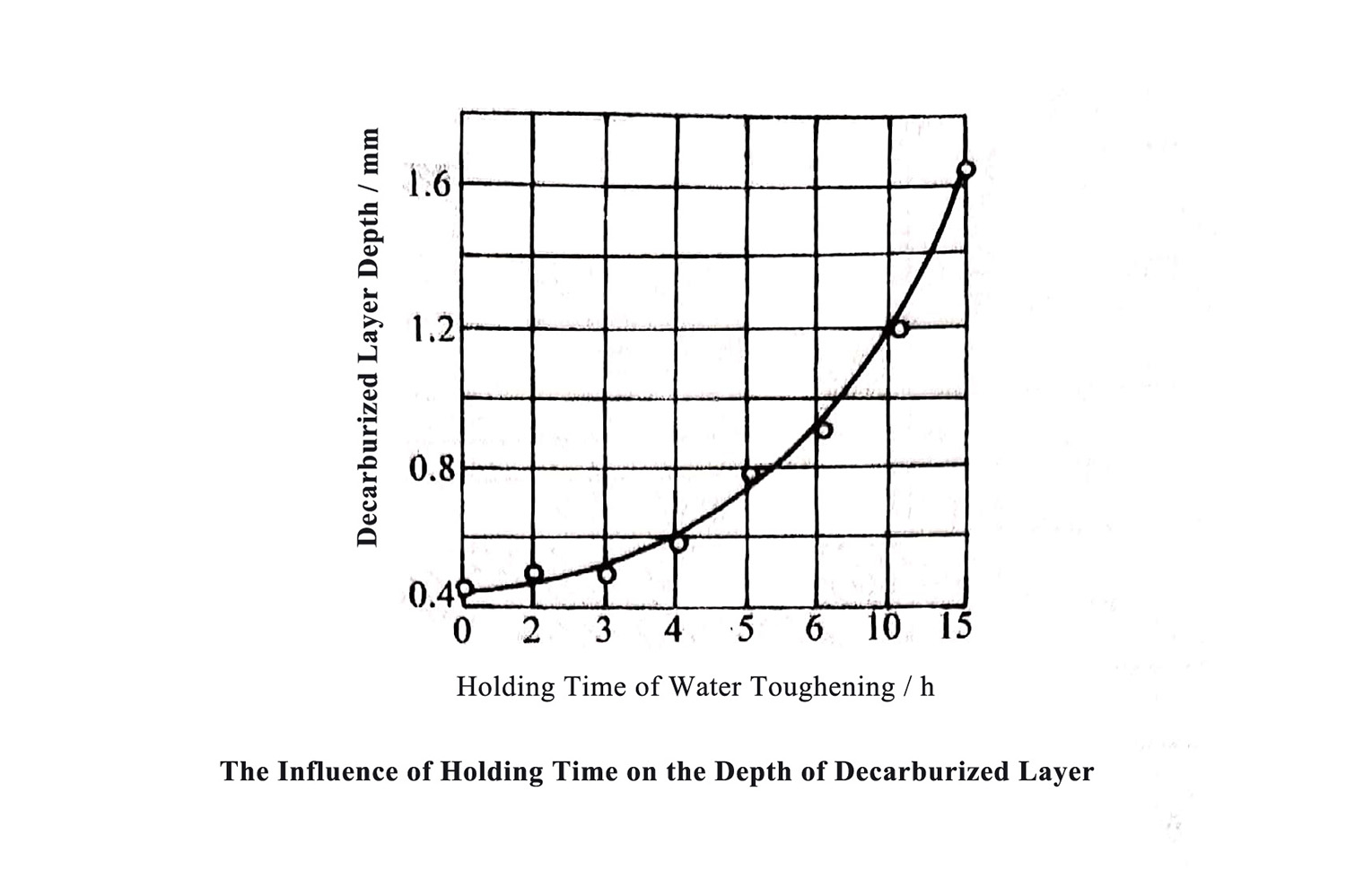

(3) Kubata nguva yemvura yakaoma kurapwa

Iyo nguva yekubata yekuomesera kwemvura kurapwa kunonyanya kuenderana nehupamhi hwemadziro ekukanda, kuitira kuve nechokwadi chekuparara kwakazara kwecarbides mune as-cast chimiro uye homogenization yeiyo austenite chimiro. Mumamiriro ezvinhu akajairwa, inogona kuverengerwa nekuwedzera nguva yekubata neawa imwe yega yega 25 mm kuwedzera kwehukobvu hwemadziro.

(4) Kutonhodzwa kwemvura inoomesera kurapwa

Iyo yekutonhodza maitiro ine simba guru pane indekisi yekuita uye chimiro chekukanda. Munguva yekuomesa mvura, tembiricha yekukanda isati yapinda mumvura inofanira kunge iri pamusoro pe950 ° C kudzivirira macarbides kubva pakunaya zvakare. Nokuda kwechikonzero ichi, nguva yenguva pakati pekukanda kunze kwechoto uye kupinda mumvura haifaniri kudarika masekondi makumi matatu. Kupisa kwemvura kunofanira kunge kuri pasi pe30 ° C kusati kwapinda mumvura, uye tembiricha yepamusoro yemvura mushure mekupinda mumvura haifaniri kudarika 50 ° C.

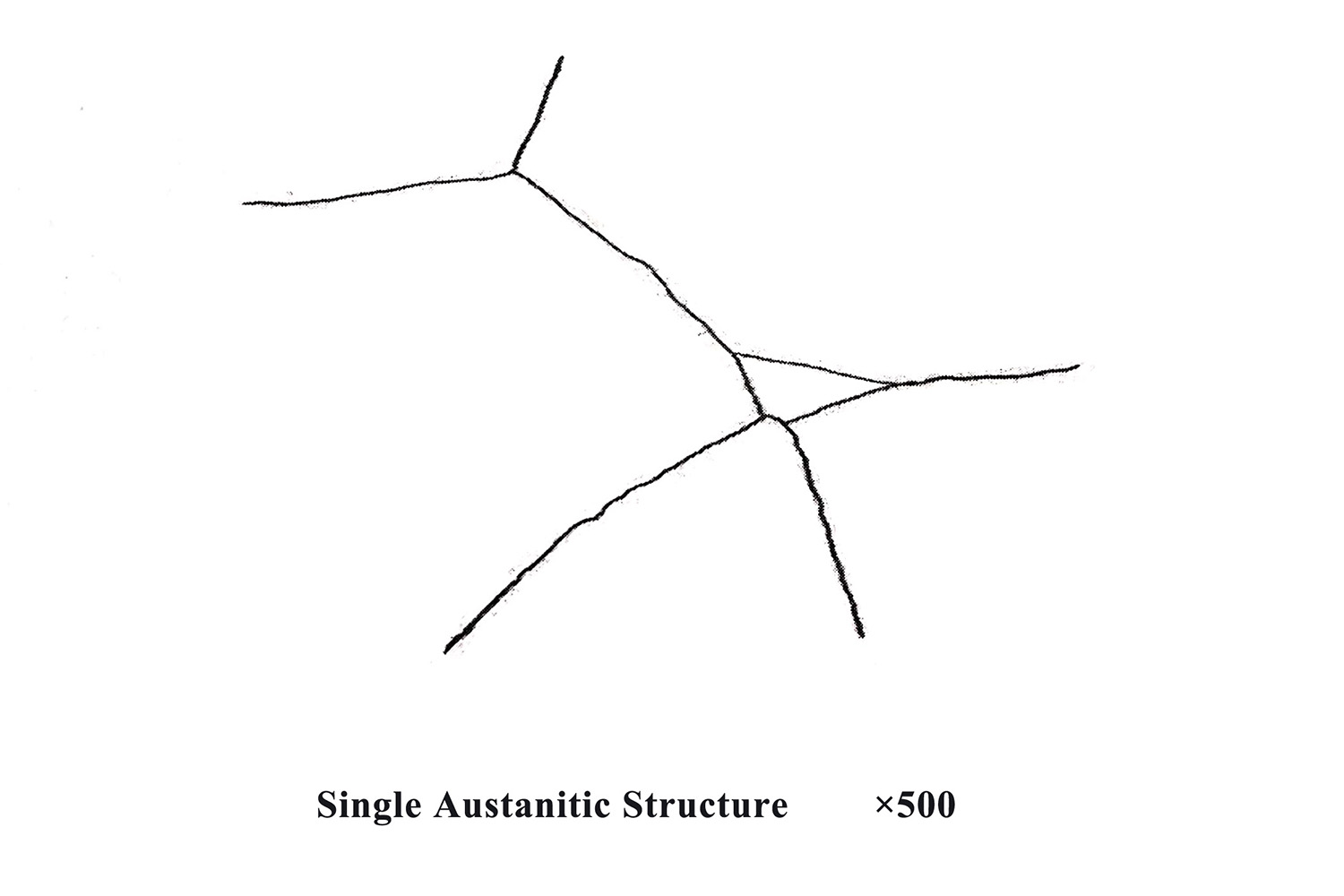

(5) Carbide mushure mekurapa kwemvura kuomarara

Mushure mekugadzirisa kwemvura kuomarara, kana iyo carbides musimbi yakakwira manganese yakabviswa zvachose, iyo metallographic chimiro chakawanikwa panguva ino chimiro chimwe chete austenite. Asi chimiro chakadaro chinogona kuwanikwa chete mune dzakatetepa-madziro castings. Kazhinji, zvishoma zvecarbides mu austenite zviyo kana pamiganhu yezviyo zvinobvumirwa. Undissolved carbides uye precipitated carbides inogona kubviswa nekupisa kurapwa zvakare. Nekudaro, eutectic carbides yakanaya nekuda kwekunyanya kupisa tembiricha panguva yekuomesa mvura kurapwa haigamuchirwe. Nekuti iyo eutectic carbide haigone kubviswa nekupisa kurapwa zvakare.

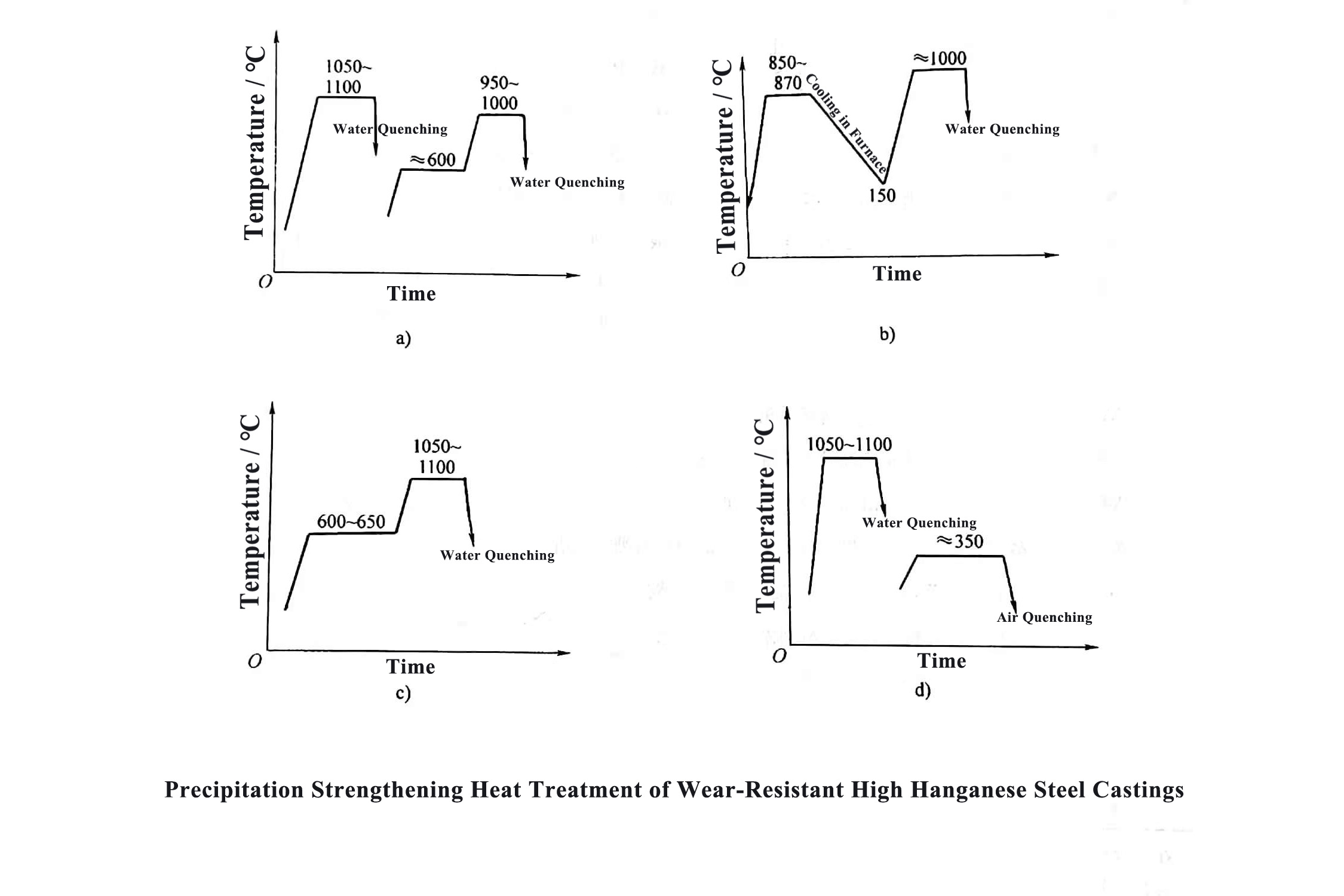

2. Kunaya Kunosimbisa Kupisa Kurapa KweKupfeka-Kudzivirira Kwepamusoro Hanganese Steel Castings

Kunaya-kusimbisa kupisa kurapwa kwekupfeka-inodzivirira yakakwira manganese simbi inoreva kuwedzerwa kwechimwe chitsama che carbide inogadzira zvinhu (senge molybdenum, tungsten, vanadium, titanium, niobium uye chromium) kuburikidza nekurapa kupisa kuti uwane humwe huwandu uye saizi mukati. high manganese simbi Chikamu chechipiri chezvakapararira carbide particles. Uku kupisa kwekupisa kunogona kusimbisa iyo austenite matrix uye kugadzirisa kupfeka kuramba kwesimbi yakakwira manganese.

3. Kupisa Kurapa kweKupfeka-kusagadzikana Kwepakati Chromium Steel Castings

Chinangwa chekupisa kurapa kwekupfeka-inodzivirira yepakati chromium simbi castings ndeye kuwana martensite matrix chimiro chine simba rakawanda, kuomarara uye kuomarara kwepamusoro, kuitira kuvandudza simba, kusimba uye kupfeka kuramba kwesimbi castings.

Kupfeka-inodzivirira yepakati chromium simbi ine yakawanda chromium zvinhu uye ine yakanyanya kuoma. Naizvozvo, yakajairika kupisa kupisa nzira: mushure 950 ℃-1000 ℃, ayo austenitization, ipapo quenching kurapwa, uye nenguva tempering kurapwa (kazhinji pa200-300 ℃).

4. Kupisa Kurapa kweWear-Resistant Low-Alloy Steel Castings

Kupfeka-resistant low-alloy steel castings inobatwa nekudzima mumvura, kudzima mumafuta nemhepo inodzima zvichienderana nekuumbwa kwealloy uye kabhoni. Pearlitic kupfeka-resistant simbi yakakandwa inotora normalizing + kupisa kupisa kurapwa.

Kuti uwane martensite matrix ane simba rakakwirira, kuoma uye kuoma, uye nekuvandudza kupfeka kusagadzikana kwesimbi castings, kupfeka-resistant low-alloy steel castings inowanzodzimwa pa 850-950 ° C uye inopisa pa 200-300 ° C. .

Nguva yekutumira: Aug-07-2021