Solidification Mechanisms

Panguva yekukanda, kusimba kwekukandira kunoitika apo simbi yakanyungudutswa inoshanduka kubva pamvura ichienda kune yakasimba. Iyi nzira inogona kukamurwa zvakanyanya mumatanho matatu:nucleation, dendritic kukura,uyekuumbwa kwezviyo. Munguva ye nucleation, zvidimbu zvidiki zvakasimba zvinoumba mukati memvura yesimbi. Aya nuclei anokura kuita dendritic zvimiro, achibuda kunze kwemuti-sepateni. Chimiro chezviyo chekupedzisira checastingsinotemerwa nekukura kweaya madendrite uye kudyidzana kwawo nenzvimbo inotonhorera.

Solidification yeVarious Alloys

Akasiyana alloys anosimba munzira dzakasiyana, achipesvedzerwa nemakemikari awo ekuumbwa uye zvinopisa zvimiro:

Aluminium Alloys: Aluminium alloys anowanzo ratidza huwandu hwehuwandu hwemvura, huchibvumira kuumbwa kwakaomarara uye kutetepa. Kusimbiswa kwavo kunowanzobatanidza kuumbwa kwechimiro chakanaka, chakaenzana chezviyo. Nekudaro, aruminiyamu alloys anowanzo shrinkage porosity uye kupisa kubvarura, izvo zvinogona kukanganisa kukanda kunaka.

Iron uyeSteel Alloys: Simbi yakakandwa inoomesa neyakaomarara chimiro nekuda kweiyo yakakwira kabhoni yemukati, ichigadzira graphite flakes kana nodule. Kusimbiswa kwesimbi alloys kunosanganisira kuumbwa kwe austenite dendrites, iyo inoshanduka kuita ferrite uye pearlite pakutonhora. Iko kutonhora kweyero uye alloy kuumbwa kunonyanya kukonzeresa chimiro chezviyo uye mechanical zvimiro zvekukanda.

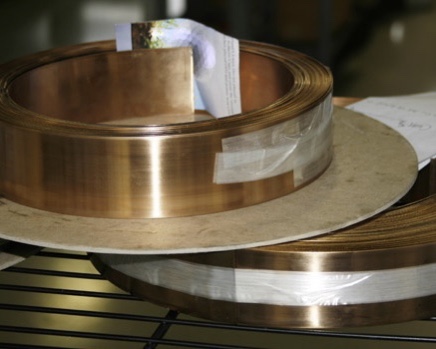

Copper Alloys: Mhangura alloys, akadai sendarira uye ndarira, kusimba ne columnar kana equiaxed zviyo chimiro. Aya ma alloys anowanzo kupatsanurwa, apo zvinhu zvakasiyana-siyana mu alloy zvakaparadzana panguva yekusimbisa, zvichiita kuti mutsauko wekuumbwa uye zvivakwa mukati mekukanda.

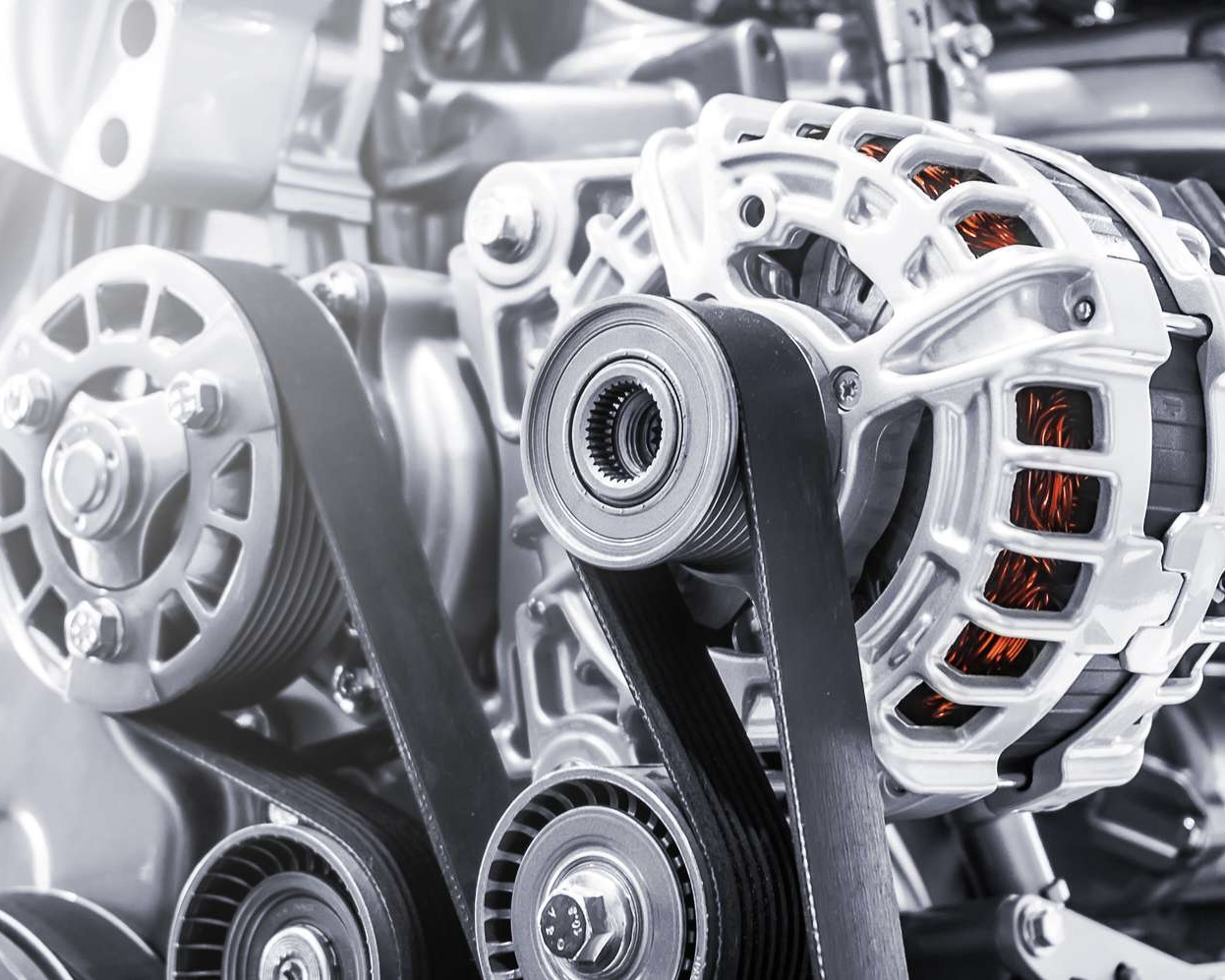

Hukama pakati peSolidification uye Casting Quality

Maitiro ekusimbisa ealloy anokanganisa zvakananga kunaka kwekukanda. Iyo yunifomu uye inodzorwa yekusimbisa maitiro yakakosha kudzikisa hurema hwakadai seporosity, kupatsanura, uye kubvarura kupisa. Semuenzaniso, kukurumidza kutonhora kunogona kutungamira mukuumbwa kwezviyo zvakanaka, kuwedzera ma mechanic properties yekukanda. Sezvineiwo, kunonoka kutonhora kunogona kukonzera kukora zviyo uye kuwedzera kukonzeresa kune hurema.

Solidification Nguva uye Speed

Iyo nguva yekusimba uye nekumhanyisa zvinokonzereswa nezvinhu zvakaita sehukuru hwekukanda, chimiro, uye nekupisa kwezvinhu zve mold. Nguva yekugadzika ndiyo nguva inodiwa pakukandira kwese kuti ishanduke kubva pamvura kuenda kune yakasimba, ukuwo sipidhi yekusimba ichireva mwero unoitika shanduko iyi.

Kukurumidza kusimba kumhanya kunowanzo kuwanikwa kuburikidza nehunyanzvi sekushandisa chill molds, iyo inokurumidza kubvisa kupisa kubva musimbi yakanyungudutswa. Izvi zvinoguma mune yakanakisa zviyo chimiro uye yakagadziridzwa ma mechanical properties. Nekudaro, kutonhora kwakanyanya kwekukurumidza kunogona kutungamirira kune kushushikana kwekupisa uye kuputika. Naizvozvo, kuwana chiyero chakakwana pakati pekusimbisa kumhanya uye kukanda mhando kwakakosha.

Nguva yekutumira: Oct-11-2024