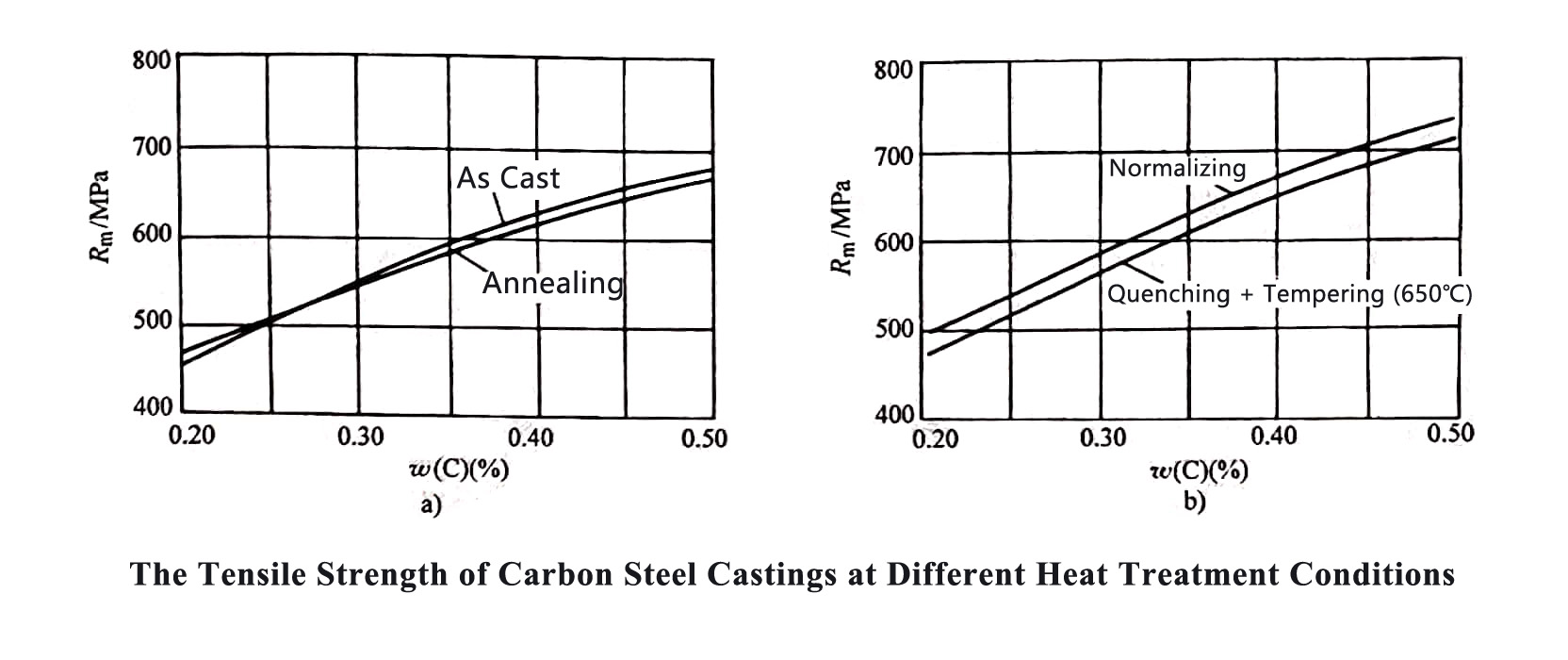

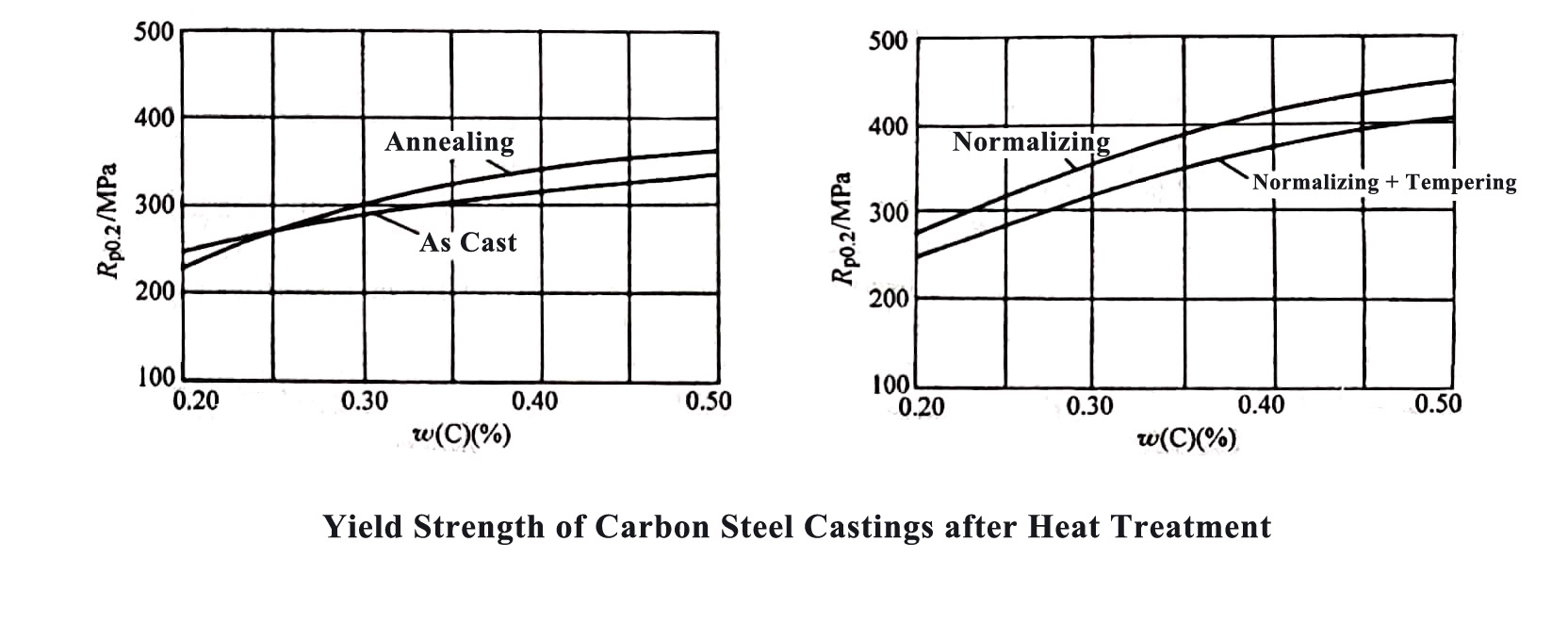

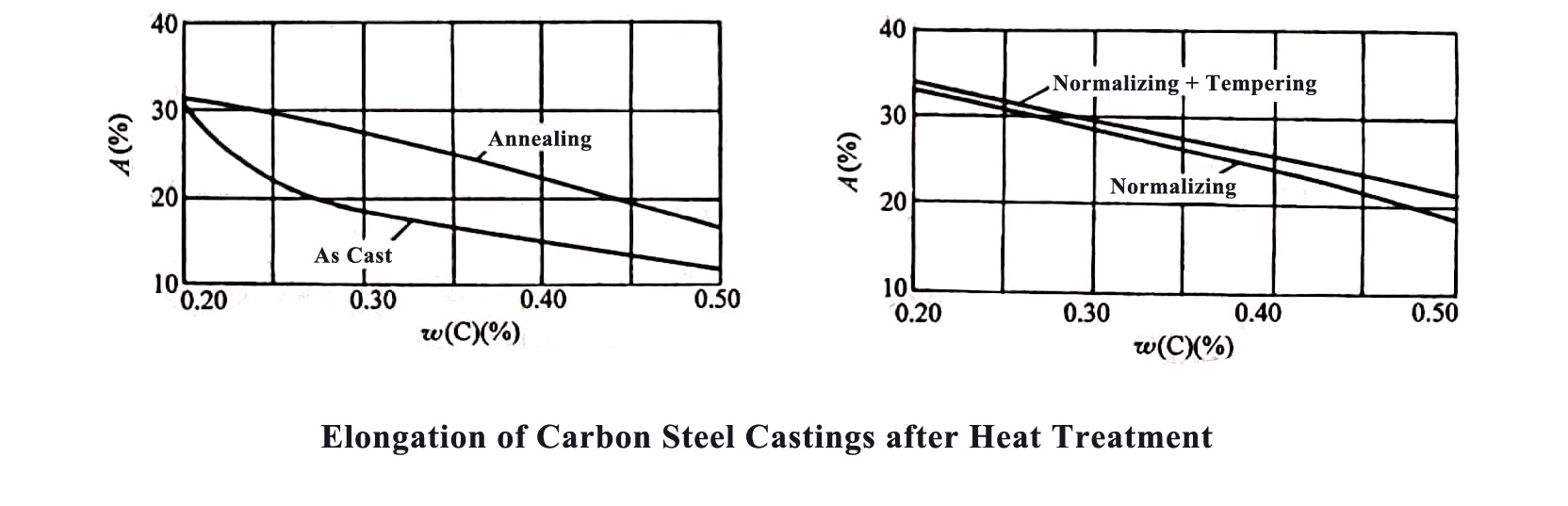

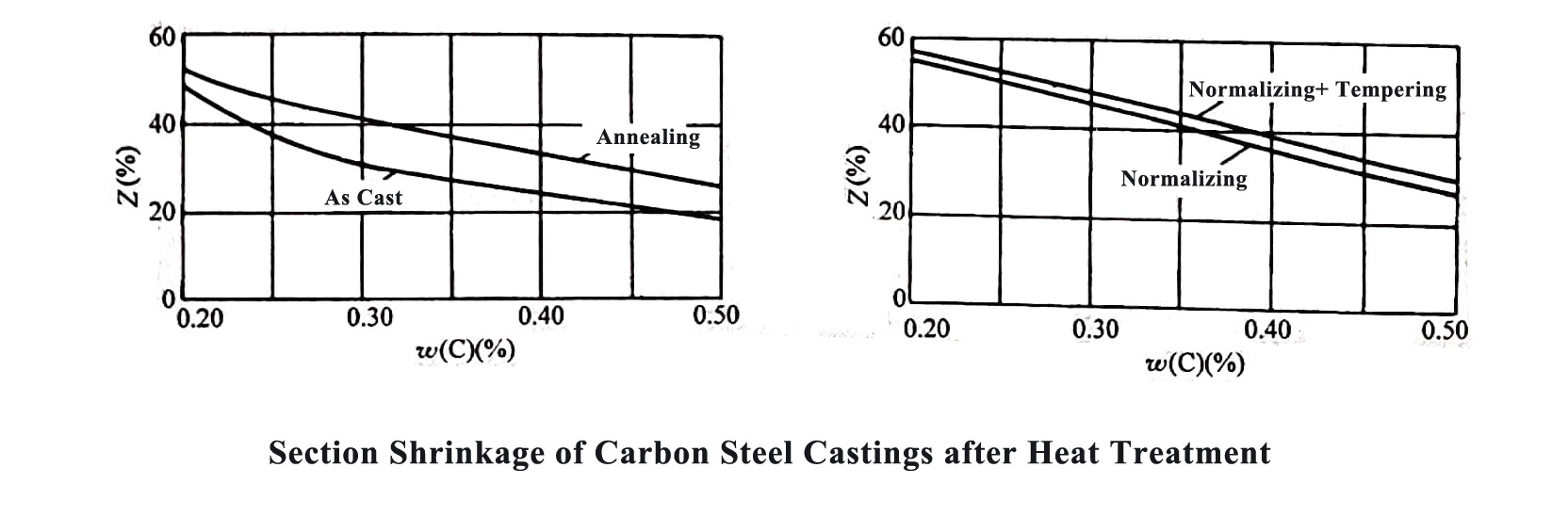

Nzira dzekupisa dzekupisa dzinowanzo shandiswa kukanda kabhoni simbi ndeidzi: annealing, normalizing kana normalizing + tempering. Kupesvedzera kweidzi nzira nhatu dzekurapa kupisa pamagetsi emidziyo yekabhoni simbi inoratidzwa mumufananidzo uri pazasi.

| Iyo Annealing Tembiricha uye Kuoma kweCarbon Steel Castings | ||||||

| Giredhi reCarbon Steel | Carbon Content / % | Annealing Tembiricha / ℃ | Kubata Nguva | Kutonhodza Nzira | Kuoma / HBW | |

| Rusvingo Hukobvu / mm | Nguva / h | |||||

| ZG200 - 400 | 0.10 - 0.20 | 910 - 880 | < 30 | 1 | Kutonhodza kusvika 620 ℃ muchoto uyezve kutonhora mumhepo | 115 - 143 |

| ZG230 - 450 | 0.20 - 0.30 | 900 - 870 | 133 - 156 | |||

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 143 - 187 | |||

| ZG310 - 570 | 0.40 - 0.50 | 870 - 840 | 30 - 100 | kuwedzera 1 awa / 30 mm | 156 - 127 | |

| ZG340 - 640 | 0.50 - 0.60 | 860 - 830 | 187 - 230 | |||

Iyo mechanic properties ye normalized cast steel yakakwira zvishoma pane iya yeannealed cast steel. Sezvo dhigirii yekudzikisa pasi panguva yekushandurwa kwechimiro chakakura, kuoma kuchava kwakakwirira, uye kushanda kwayo kwekucheka kuri nani zvakare.

| Iyo Normalizing uye Kuoma kweCarbon Steel Castings | |||||

| Giredhi reCarbon Steel | Carbon Content (%) | Normalizing Tembiricha / ℃ | Tempering | Kuoma / HBW | |

| Tembiricha / ℃ | Kutonhodza Nzira | ||||

| ZG200 - 400 | 0.10 - 0.20 | 930 - 890 | 540 - 610 | muchoto kana mumhepo | 126 - 149 |

| ZG230 - 450 | 0.20 - 0.30 | 930 - 890 | 540 - 610 | muchoto kana mumhepo | 139 - 169 |

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 550 - 620 | muchoto kana mumhepo | 149 - 187 |

| ZG310 - 570 | 0.40 - 0.50 | 890 - 850 | 550 - 650 | muchoto kana mumhepo | 163 - 217 |

| ZG340 - 640 | 0.50 - 0.60 | 870 - 830 | 550 - 650 | muchoto kana mumhepo | 187 - 228 |

Kune kabhoni simbi castings ine yakakwira kabhoni yemukati uye maumbirwo akaomarara, kuitira kubvisa kusara kunetseka uye kuvandudza kuoma, kurapwa kwekupisa kunogona kuitwa mushure mekugara. Tembiricha yekudziya inowanzo 550 ℃-650 ℃, yozotonhorera mumhepo.

Kana iyo kabhoni yemukati yakakwira kupfuura 0.35%, iyo yakakandwa kabhoni simbi zvikamu zvinogona zvakare kudzimwa nekudzikamiswa (kudzimwa + tembiricha yakadzikama). Diki kabhoni simbi castings anogona kudzima zvakananga uye kushatirwa mu-as-cast state; yakakura kana yakaoma-yakaumbwa-yakaumbwa kabhoni simbi castings inofanira kudzimwa uye kushatirwa mushure mekujaira.

| Iko Kudzima uye Kupisa Tembiricha uye Kuoma kweCarbon Steel Castings | |||

| Carbon Content % | Kudzima Tembiricha / ℃ | Kupisa Tembiricha / ℃ | Kuoma Mushure meKupisa / HBW |

| 0.35 - 0.45 (Batch Diki) | 850 - 830 (Kutonhora Mumvura) | 300 - 400 | 364 - 444 |

| 400 - 450 | 321 - 415 | ||

| 510 - 550 | 241 - 286 | ||

| 540 - 580 | 228 - 269 | ||

| 580 - 640 | 192 - 228 | ||

| 0.45 - 0.55 (Batch Diki) | 830 - 810 (Kutonhora Mumvura kana Mafuta) | 550 - 630 | 220 - 240 |

| 450 | ≈ 269 | ||

| 550 | ≈ 248 | ||

| 650 | ≈ 228 | ||

| 0.30 - 0.40 (Batch reMizhinji) | 840 -880 (Kutonhora Mumvura kana Mafuta) | 520 - 550 | 229 - 269 |

| 530 - 560 | 217 - 255 | ||

| 540 - 570 | 207 - 241 | ||

| 550 - 580 | 187 - 229 | ||

| 0.40 - 0.50 (Batch reMizhinji) | 820 - 840 (Kutonhora Mumvura kana Mafuta) | 530 - 560 | 229 - 269 |

| 550 - 580 | 217 - 255 | ||

| 560 - 590 | 207 - 241 | ||

| 570 - 600 | 187 - 229 | ||

Nguva yekutumira: Jul-23-2021