Tsika kana yakajairika Stainless simbi 316 camlock byinvestment casting processuye CNC machining.

Simbi isina simbi ine hushoma hwe chromium inosvika 10.5%, zvichiita kuti isarambe iine corrosive liquid environments uye kuoxidation. Zvisinei, izvi hazvisi mhedziso. Stainless simbi yekukandira mari "inodzivirira kupisa" kana ichishandiswa munzvimbo dzemvura uye mhute iri pasi pe1200°F (650°C) uye "inodzivirira kupisa" kana ichishandiswa pamusoro petembiricha iyi. AISI 316 is an austenitic Stainless simbi iyo inoshandiswa zvakanyanya pakudyara kwekudyara.

Austenitic Stainless simbi inofanirwa kuve yakasimba-solution yakabatwa isati yashandiswa, kuitira kuti iwedzere mhinduro yakasimba yezvakasiyana maprecipitates senge carbides musimbi mune austenite matrix, ukuwo homogenizing chimiro uye kubvisa kushushikana, kuitira kuve nechokwadi chakanakisa Corrosion kuramba uye mechanical properties. Iyo chaiyo mhinduro yekurapa sisitimu kutonhora kwemvura mushure mekudziya pa1050~1150 ℃ (zvikamu zvitete zvinogona zvakare kutonhodzwa nemhepo). Iyo tembiricha yekurapwa kwemhinduro inoenderana nedhigirii rekusanganiswa kwesimbi: Molybdenum-isina kana yakaderera-molybdenum simbi mamakisi anofanirwa kuve akaderera (≤1100 ℃), uye epamusoro alloyed mamakisi akadai 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, nezvimwewo inofanira kunge yakakwira ( 1080~1150) ℃).

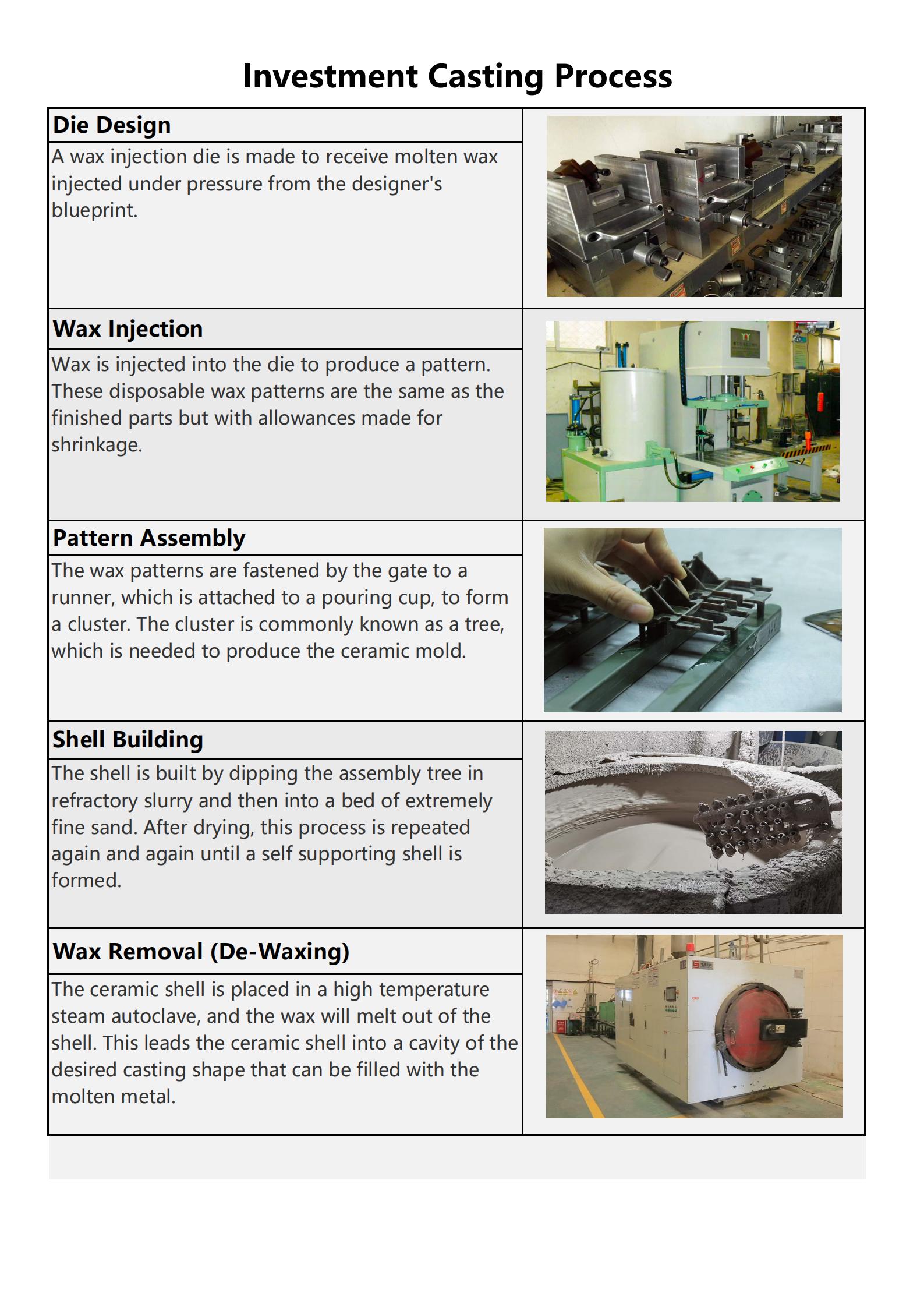

Kugona kwe Investment Casting Foundry:

- • Kukura Kwepamusoro: 1,000 mm × 800 mm × 500 mm

- • Weight Range: 0.5 kg - 100 kg

- • Kwegore Kukwanisa: 2,000 matani

- • Bond Materials for Shell Building: Silica Sol, Water Glass nemisanganiswa yawo.

- • Kushivirira: Pakukumbira.

Zvakanakira Investment Casting Components:

- - Yakanakisa uye yakatsetseka pamusoro pekupedzisira

- - Tight dimensional tolerances.

- - Yakaoma uye yakaoma maumbirwo ane dhizaini inoshanduka

- -Kugona kukanda madziro matete saka chinhu chakareruka chekukanda

- -Kusarudzwa kwakakura kwesimbi dzakakandwa uye alloys (ferrous uye isiri-ferrous)

- - Draft haidiwe mukugadzira molds.

- - Deredza kudiwa kwechipiri machining.

- - Kurasa zvinhu zvakaderera.

| Materials forInvestment CastingMaitiro paRMC Foundry | |||

| Category | China Grade | US Giredhi | Germany Giredhi |

| Ferritic Stainless Simbi | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Simbi | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic simbi isina tsvina | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.44404, 1.4404, 9 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Kunaya Kuomesa Stainless Simbi | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Simbi | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Simbi | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

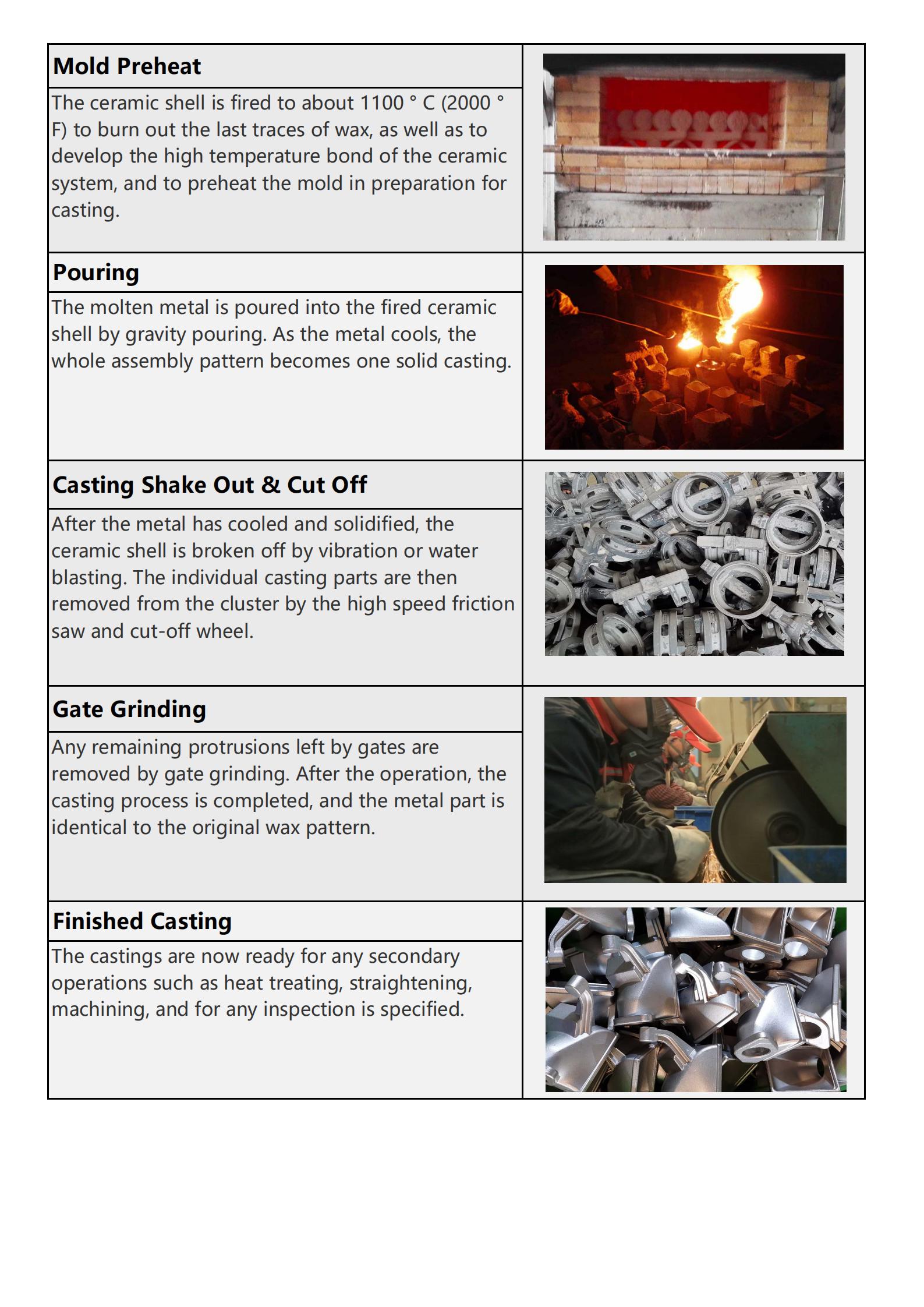

| INVESTMENT CASTING TOLERANCES | |||

| Inches | Mamirimita | ||

| Dimension | Kushivirira | Dimension | Kushivirira |

| Kusvika ku0.500 | ±.004" | Kusvika ku12.0 | ± 0.10mm |

| 0.500 kusvika 1.000" | ±.006" | 12.0 kusvika 25.0 | ± 0.15mm |

| 1.000 kusvika 1.500" | ±.008" | 25.0 kusvika 37.0 | ± 0.20mm |

| 1.500 kusvika 2.000" | ±.010" | 37.0 kusvika 50.0 | ± 0.25mm |

| 2.000 kusvika 2.500" | ±.012" | 50.0 kusvika 62.0 | ± 0.30mm |

| 2.500 kusvika 3.500" | ±.014" | 62.0 kusvika 87.0 | ± 0.35mm |

| 3.500 kusvika 5.000" | ±.017" | 87.0 kusvika 125.0 | ± 0.40mm |

| 5.000 kusvika 7.500" | ±.020" | 125.0 kusvika 190.0 | ± 0.50mm |

| 7.500 kusvika 10.000" | ±.022" | 190.0 kusvika 250.0 | ± 0.57mm |

| 10.000 kusvika 12.500" | ±.025" | 250.0 kusvika 312.0 | ± 0.60mm |

| 12.500 kusvika 15.000 | ±.028" | 312.0 kusvika 375.0 | ± 0.70mm |