Cast iron, iyo inonyanya kuvhara grey cast iron, ductile cast iron, cast mealleable iron uye imwe high alloy cast iron, inoshandiswa zvakanyanyaRMC Casting Foundry. The cast iron castings inoita basa rakakosha mumaindasitiri emazuva ano. Kuti usarudze nzira dzakakodzera uye dzakakodzera dzekukanda dzakagadzirwa nesimbi yakakandwa ichakubatsira iwe kuwana simbi yekukanda pamutengo wakaderera uye nguva pfupi yekutungamira.

Pano pane zvinotevera tinokurudzira mamwe misimboti kana zvinhu kana tasarudzamaitiro ekukanda akakodzeranokuda kwesimbi yakaumbwa. Kazhinji, iyo inonyanya kushandiswa simbi yekukanda maitiro ndeyekukanda jecha, inoteverwa neakakosha nzira dzekukanda, senge simbi mold casting, investigative casting, shell molding casting,kurasika furouye vacuum casting.

1- Kukandwa kwejecha kunofanira kunge kuri Yekutanga Sarudzo

Kunyanya nekuda kwemutengo wakaderera uye nyore kugadzirwa kwejecha kukanda nzira, kukanda jecha kwatora 60% kusvika 70% yehuwandu hwekukanda kugadzirwa, uye inenge 70% iyo ijecha rakasvibirira. Kana jecha rakasvibirira risingakwanisi kuita zvinodiwa uye ipapo unogona kufunga nezvekushandiswa kwejecha rakaoma kana rimwe jecha. Huremu hwehuremu hwekukanda jecha rakasvibira hunobva pamakirogiramu akati wandei kusvika kumazana emakirogiramu, nepo kugadzirwa kwevhu rakaoma kukanda kunogona kurema matani akati wandei.

Kukanda jecha kunoshandisa marudzi ejecha kugadzira mold. Inogonawo kukamurwa kuva marudzi matatu:

1) Green Sand Kukanda, iyo inoshandisa jecha rakanyorova (regirini) kugadzira mold.

2) Resin Coated Sand Kukandauye No-bake Sand Mold Casting (Self-hardening Resin Sand Casting), iyo inoshandisa makemikari akasungwa zvinhu kuti abatsire kuumba maitiro ekuumba.

3) Dry Sand Casting, iyo inonyanya kushandisa yakaoma pasina makemikari mateials ekuumba. Kukandwa kwejecha rakaoma kunonyanya kureva kukanda furo rakarasika uyevacuum casting.

Kazhinji kutaura, kune epakati uye yakakura simbi yekukandira, yekuzviomesa nejecha resin kukanda ndiyo yakanaka sarudzo. Asi nezve alloy simbi uye kabhoni simbi zvinhu, tinogona kusarudza mvura girazi jecha. Izvi zvinogona kuwana zviyero zvakaringana, yakatsetseka pamusoro peiyo castings, nepo ine yakaderera mutengo pane silica sol investimendi yekukandira maitiro.

Iko kurongeka, kupera kwepamusoro, kusimba kwezvinhu uye microstructure, mechanical properties inogona kusasvika kune dzakaoma requriemenets kana uine zvakakosha uye zvakakwirira zvinotarisirwa. Muchiitiko ichi, dzimwe nzira dzekukanda dzakadai sesilica sol kana girazi rekudyara remvura, kukanda kufa, kukanda kwakadzika kukanda, kurasika foam uye kukanda vacuum kunofanirwa kutorwa mumaziso edu.

2- Funga Nezve Chido Chegore

Kana yako yegore yekuda yakakwira, iyo otomatiki yekuumba mutsara inofanirwa kuve sarudzo yakanyanya kunaka nekuda kwehukuru hwayo hwekugadzira uye yakatsiga mhando. Uye nzira iyi yaigona kusvika yakaderera avhareji mari chete kana inodiwa uwandu yakakura zvakakwana. Nepo, kuumba nemaoko kuchachengetedza mitengo yako kana huwandu hwako husina kukura zvakanyanya, kana madhirigi aunoda ari epakati nepakati kana hukuru.

Nekudaro, iyo resin jecha mold (shell moulding) yekukanda maitiro inokodzerawo kukanda simbi yehukuru hukuru. Zvakare, iyo shell casting ine kupedzisa kuri nani uye yemhando yepamusoro ipapo girinhi jecha rekukanda maitiro.

Mamwe maitirwo akadai seyakaderera kukanda kufa, kufa kukandira, centrifugal casting inokodzera chete kugadzirwa kwakawanda nehuwandu hukuru nekuda kwemidziyo inodhura uye maturusi.

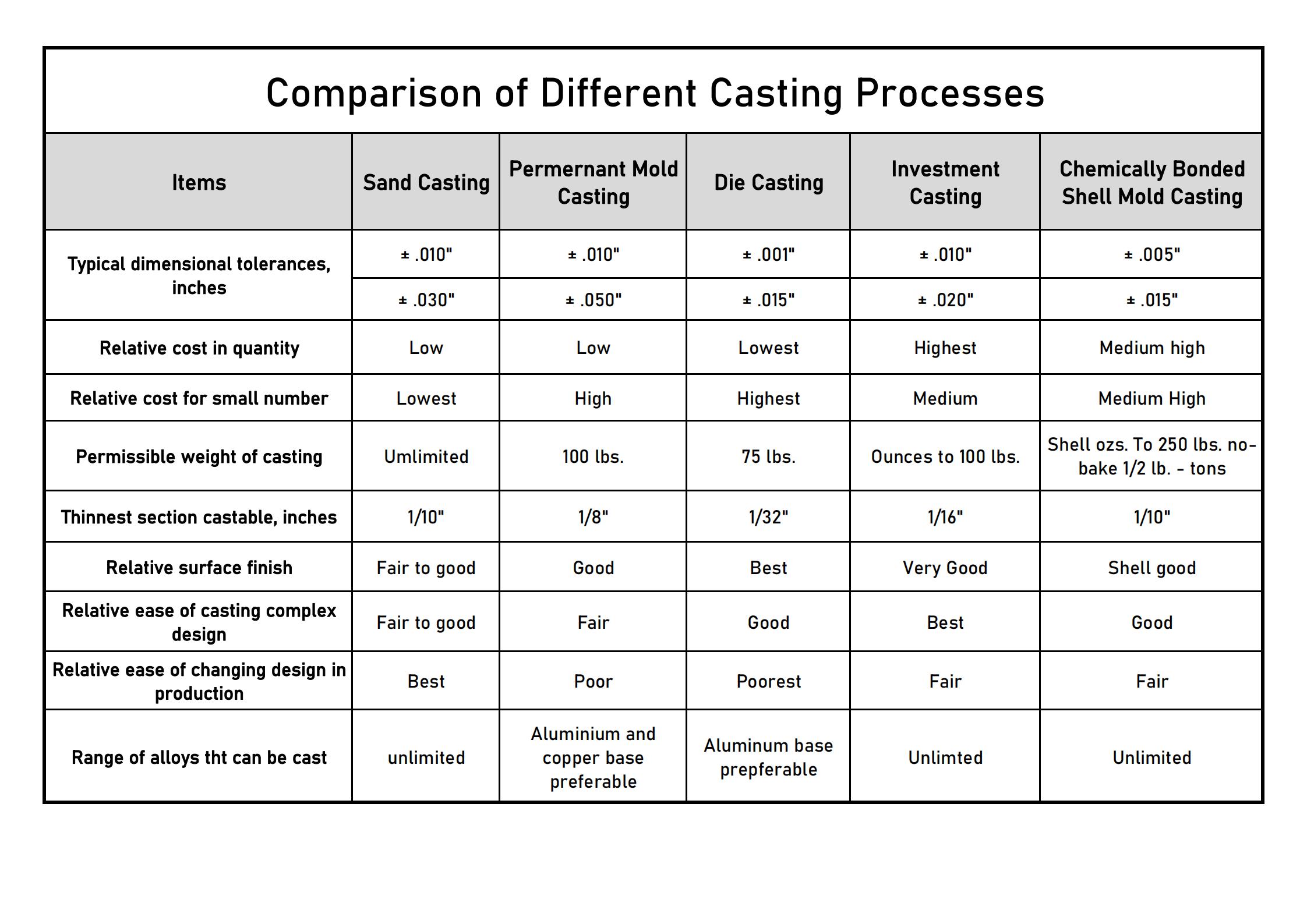

3- Dimensional Tolerances uye Surface Quality Count

Mukati mekusarudza nzira yekukanda yesimbi yakakandwa zvinhu, kurongeka kwedimensional uye kunaka kwepamusoro kwakakoshawo. Kusarudza aprecision casting processichaderedza kudiwa kwekugadzira, kunyange pasina machining. Izvi zvinoda kunyatsotariswa kwechiyero pakati pekuwedzera kwemitengo yekukanda uye kuderedzwa kwekugadzira. Zvichienderana nemakore edu mazhinji echiitiko, mainjiniya ekambani yedu anogona kukusarudzira yakanyatsokodzera uye ine mari yekukanda maitiro.

Nguva yekutumira: Jan-28-2021