PaRMC Casting Foundry, tinotora iyoresin yakavharwa nejecha mold(hapana kubheka uye kuzviomesa maitiro) kukanda ndarira, ndarira uye mamwe mhangura akavakirwa alloys.

Brass castingsanoshandiswa zvakanyanya muvharuvhu uye pombi munda nekuda kwekuita kwakanaka kwezvinhu zvendarira. PaRMC Foundry, isu tinonyanya kugadzira iyondariranekukanda jecha rakasvibirira, resin yakavharwa nejecha kukanda,Investment castinguye nokuda kwekukandwa kukuru kwendarira, tinotorawo yakarasika foam casting uye vacuum casting process. Kazhinji, kukanda kwendarira kunogadzirwa nejecha kukanda ndiyo chikamu chikuru mune yedu yekutanga.

A alloy yemhangura ine zinc sechinhu chikuru chekubatanidza chinowanzonzi ndarira. Copper-zinc binary alloy inonzi yakajairwa ndarira, uye ternary, quaternary kana multi-element ndarira inoumbwa nekuwedzera hushoma hwezvimwe zvinhu pahwaro hwemhangura-zinc alloy inonzi yakakosha ndarira. Cast brass inoshandiswa kugadzira ndarira yekukandira. Brass castings inoshandiswa zvakanyanya mukugadzira michina, vharafu uye pombi, ngarava, ndege, mota, kuvaka uye mamwe maindasitiri zvikamu, zvichitora humwe huremu mune inorema isiri-ferrous simbi zvinhu, kugadzira cast brass series.

Kuenzaniswa nendarira nendarira, iyo yakasimba solubility ye zinc mumhangura yakakura kwazvo. Pasi peyakajairika tembiricha yakaenzana, inenge 37% ye zinc inogona kunyungudutswa mumhangura, uye inenge 30% ye zinc inogona kunyungudutswa mu as-cast state, nepo tin bronze Mu as-cast state, chikamu chikuru chekunyungudika kwakasimba kwetin. mumhangura inongova 5% kusvika 6%. Chikamu chikuru chekunyungudika kwakasimba kwealuminium bronze mumhangura inongova 7% kusvika 8%. Naizvozvo, zinc ine yakanaka yakasimba mhinduro inosimbisa mhedzisiro mumhangura. Panguva imwecheteyo, zvinhu zvakawanda zvinogadziriswa zvinogonawo kunyungudutswa mumhangura kune madhigirii akasiyana , Kuwedzera kunatsiridza maitiro ayo emagetsi, kuitira kuti mhangura, kunyanya imwe ndarira yakakosha ine maitiro esimba guru. Mutengo wezinc wakadzikira pane wealuminium, mhangura, netin, uye yakapfuma muzviwanikwa. Nhamba ye zinc yakawedzerwa kundarira yakakura, saka mari yendarira yakaderera pane tin bronze uye aluminium bronze. Brass ine diki yekusimbisa tembiricha renji, yakanaka fluidity, uye nyore kunyungudika.

Nekuti ndarira ine hunhu hwadudzwa pamusoro hwekusimba kwepamusoro, mutengo wakaderera uye kuita kwakanaka kwekukanda, brass ine mhando dzakawanda, yakakura kubuda uye kushanda kwakafara kupfuura tin bhuronzi uye aluminium bronze mune alloys emhangura. Nekudaro, iyo yekupfeka kuramba uye corrosion kuramba kwendarira haina kunaka sebhuronzi, kunyanya iyo corrosion kuramba uye kupfeka kuramba kwendarira yakajairika kwakadzikira. Chete kana zvimwe zvinhu zvealloy zvawedzerwa kuti zviumbe akasiyana siyana akakosha ndarira, kusamira kwayo kupfeka uye kuramba corrosion kuita kwakagadziridzwa nekuvandudzwa.

Serudzi rwejecha rinozviomesa rega, jecha re-no-bike furan resin rinoshandiswa zvakanyanya kugadzira grey iron jecha uye maitiro ekukanda simbi. Kumusoro kwejecha mold yaizosimbiswa kune yakaoma mamiriro mushure mekupisa kwekuputira. Naizvozvo, iyo furan resin jecha nzira yekukanda inogona kushandiswa kugadzira epakati-saizi uye yakakura-hukuru-hukuru simbi yekukanda zvikamu, kubva pamakumi emakirogiramu kusvika kunyange makumi ematani. Nemhando yakanaka yepamusoro, kushivirira kwakasimba uye kushomeka kwekukanda, iyo furan resin jecha maitiro ekukanda anogona kushandiswa kugadzira zvikamu zvakaoma zvekukanda.

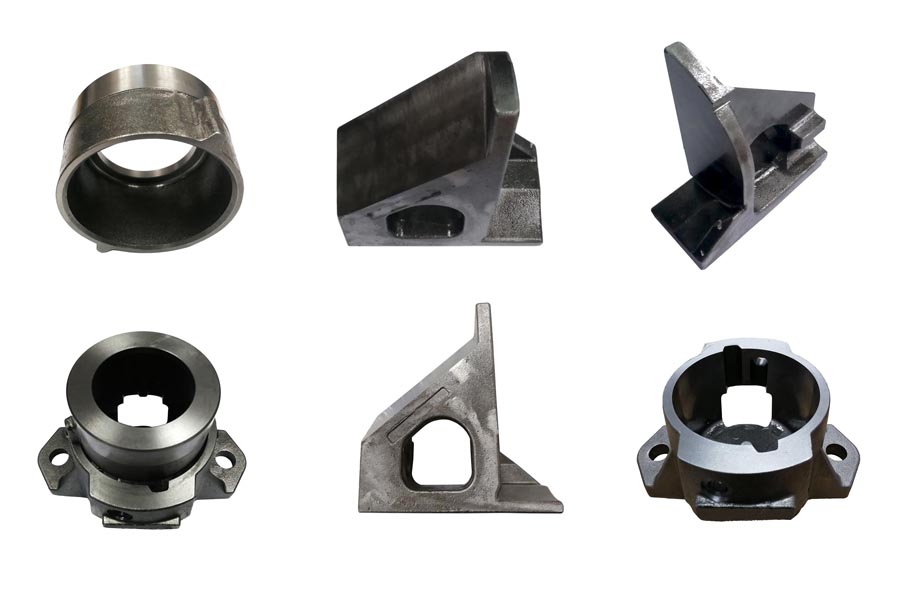

RMC inoshandisa iyo No-bake jecha rekukanda maitiro kugadzira simbi yekukandira, Stainless simbi castings, ductile iron castings, uye grey iron castings. Muchiitiko cheNo-Bake, zviumbwa zvejecha zvinoumbwa nehuni kana simbi. Ijecha rezviyo zvakatsetseka rinosanganiswa ne resin binder mune yakakwirira-kumhanya jecha musanganisi uye wobva wadonha mubhokisi rine maitiro. Maminitsi mashomanana gare gare, musanganiswa wejecha-binder unozviomesa uye mold inobviswa kubva pamaitiro. Sand Cores yekugadzira iyo yemukati dhizaini yekukanda inogadzirwa uchishandisa iyo imwechete maitiro panguva imwe chete. Mushure mokunge macores uye kunze kwekuumbwa zvaunganidzwa, zvakavharwa uye zvakagadzirirwa kudira simbi. Zvimwe zvinhu, senge ductile iron castings, zvinoda kurapwa kwakakosha kwesimbi isati yadururwa. Iyo No-Bake casting process inochinjika zvakanyanya sezvo ichibvumira simbi castings uye simbi castings kuti ichengetwe kune chaiyo kushivirira uku uchikwanisa kubata zvidimbu zvikamu kubva kumakumi emagiramu kusvika kumakumi ematani.

Matanho eNo Bake Shell Casting process:

No bake inzira yekukandira iyo inosanganisira kushandiswa kwemakemikari anosunga kubatanidza jecha rekuumbwa. Jecha rinoendeswa kune mold fill station kugadzirira kuzadza mold. Musanganisi unoshandiswa kubatanidza jecha nekemikari binder uye catalyst. Sezvo jecha richibuda muvhenganisi, binder rinotanga kuita kemikari yekuomesa. Iyi nzira yekuzadza mold inogona kushandiswa kune imwe neimwe hafu ye mold (kubata uye kudhonza). Hafu yega yega mold inobva yabatanidzwa kuti iite yakasimba uye yakaoma. A rollover inobva yashandiswa kubvisa mold hafu kubva mubhokisi remuenzaniso. Mushure mekunge jecha rakagadzika, mold wash inogona kushandiswa. Cores, kana zvichidikanwa, zvinoiswa mukati mekudhonza uye cope inovharwa pamusoro pemacores kuti ipedze mold. Mutsetse wemota dzinobata mold uye maconveyor anofambisa mold panzvimbo yekudira. Kana yadirwa, mold inobvumirwa kutonhora isati yazununguswa. Kuzunza-zunza kunosanganisira kutyora jecha rakaumbwa kubva pakukandwa. Kukandira kunobva kwaenda kunzvimbo yekukandira yekupedzisa yekubvisa simiti, kukanda kupedzisa uye kupedzisa. Zvimedu zvakaputsika zvejecha rakaumbwa zvinozopwanywazve kusvikira jecha radzorerwa pakukura kwezviyo. Jecha racho zvino rinogona kudzoserwa kuti rizoshandiswazve mukukanda kana kubviswa kuti riraswe. Thermal reclamation ndiyo inonyanya kushanda, yakakwana nzira yekusabika jecha reclamation.

| Zvishandiso zveShell Mold Casting paRMC Foundry | |

| Metal & Alloys | Popular Giredhi |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodualar) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | SH-GJS-800-8, SH-GJS-1000-5, SH-GJS-1200-2 |

| Carbon Steel | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Simbi isina ngura | Ferritic Stainless Simbi, Martensitic Stainless Simbi, Austenitic Stainless Simbi, Kunaya Kuomesa Stainless Simbi, Duplex Stainless Simbi |

| Aluminium Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Brass / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, uye GB | |