OEM tsika vacuum yekukanda zvigadzirwa zvegrey iron uye spheroidal graphite (SG) ductile nodular cast iron ine kupisa kurapwa, pamusoro pekurapa uye CNC machining sevhisi.

Vacuum Casting inodaidzwa zvakare kuti Negative Pressure Seal Casting, Yakaderedzwa Pressure Casting kana V process Casting. Vacuum pressure casting inoda kushandiswa kwemidziyo yekubvisa mweya kuburitsa mweya mukati memushonga wekukanda, wobva washandisa mutsauko wekumanikidza pakati pemukati nekunze kwe mold kuvhara firimu repurasitiki rinopisa pane pateni uye template. Iyo mold yekukanda ichave yakasimba zvekukwanisa kumira nesimbi yakanyungudutswa panguva yekukanda. Mushure mekuwana vacuum mold, zadza bhokisi rejecha nejecha rakaoma risina binder, uye wobva wavhara pamusoro pejecha nefirimu repurasitiki, rinoteverwa nevhayumu kuita kuti jecha rive rakasimba uye rakasimba. Mushure maizvozvi, bvisa mold, isa jecha cores, vhara mold kuti uite everthing kugadzirira kudururwa. Pakupedzisira, kukanda kunowanikwa mushure mokunge simbi yakanyungudutswa yatonhodzwa uye yasimbiswa.

| Yakarasika Foam Casting vs Vacuum Casting | ||

| Item | Yakarasika Foam Kukanda | Vacuum Casting |

| Yakakodzera Castings | Madiki uye epakati-saizi castings ane yakaoma cavities, akadai injini block, injini chivharo | Zvikamu zvepakati uye zvakakura zvine maburi mashoma kana asina, senge simbi yakakandwa counterweights, cast iron axle housings. |

| Patani uye Ndiro | Foam maitiro akagadzirwa ne moldings | Template ine suction box |

| Sand Bhokisi | Pasi kana mativi mashanu anopera | Mativi mana anopera kana ane exhaust pombi |

| Plastiki Firimu | Chivharo chepamusoro chakavharwa nemafirimu epurasitiki | Mativi ese emahafu maviri ebhokisi rejecha akavharwa nemafirimu epurasitiki |

| Coating Materials | Pendi ine mvura ine coating gobvu | Doro-based pendi nemucheka mutete |

| Molding Sand | Jecha rakaomarara | Jecha rakanaka rakaoma |

| Vibration Molding | 3D Vibration | Vertical kana Horizontal Vibration |

| Kudira | Negative Kudira | Negative Kudira |

| Sand Process | Bvisa dzvinyiriro isina kunaka, shandura bhokisi kuti udonhedze jecha, uye jecha rinozoshandiswa zvakare | Bvisa kudzvinyirira kwakashata, ipapo jecha rakaoma rinowira muchiratidziro, uye jecha rinoshandiswazve |

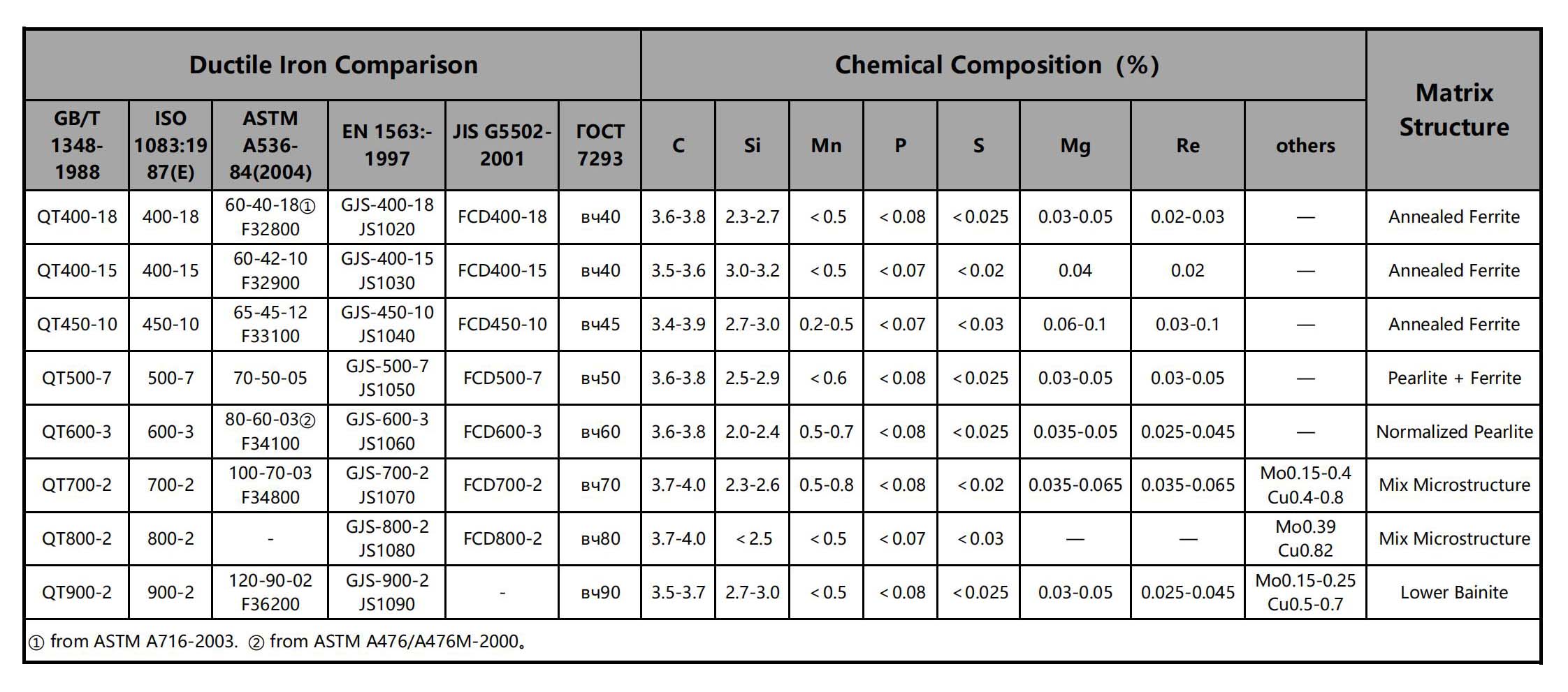

Ductile cast iron, iyo inonziwo nodular cast iron, spheroidal graphite cast iron kana kungoita SG iron kwenguva pfupi, inomiririra boka resimbi yakakandwa. Nodular cast iron inowana nodular graphite kuburikidza ne spheroidization uye inoculation kurapwa, iyo inobudirira inovandudza ma mechanic properties yesimbi yakakandwa, kunyanya plastiki uye kuoma, kuitira kuti uwane simba rakakwirira kudarika carbon steel.

Ductile iron castings ine zvirinani kunyura kuita pane kabhoni simbi, nepo kabhoni simbi castings ine zvirinani weldability. Uye kune imwe nhanho, iyo ductile iorn castings inogona kunge iine mamwe maitiro ekupikisa kupfeka uye ngura. Saka iyo ductile iron casting inogona kushandiswa kune dzimwe dzimba dzepombi kana masisitimu ekupa mvura. Nekudaro, isu tichiri kuda kuita matanho ekudzivirira kubva pakupfeka uye ngura.

Ductile iron haisi chinhu chimwe chete asi chikamu cheboka rezvinhu zvinogona kugadzirwa kuti zvive nehuwandu hwezvinhu kuburikidza nekutonga kwe microstructure. Izvo zvinowanzotsanangudza hunhu hweboka iri rezvinhu chimiro chegraphite. Mune ductile irons, iyo graphite iri muchimiro chemanodule kwete maflakes sezvairi mugrey iron. Iyo yakapinza chimiro chemaflakes e graphite inogadzira kushushikana pfungwa mukati mesimbi matrix uye yakatenderedzwa chimiro chemanodule zvishoma, nekudaro kuvharidzira kusikwa kwekutsemuka uye nekupa iyo inosimudzira ductility inopa alloy zita rayo. Saka kazhinji kutaura, kana iyo ductile iron ichigona kuzadzisa zvaunoda, iyo ductile iron inogona kuve yako yekutanga sarudzo, pachinzvimbo chekabhoni simbi yekukanda kwako.