Cobalt yakavakirwa alloy investimendi yekukandira zvigadzirwa kubva kuChina yekutanga yakawanikwa ine kupisa kurapwa uye CNC machining masevhisi

| Metals forInvestment Casting Processku RMC | |||

| Category | China Grade | US Giredhi | Germany Giredhi |

| Carbon Steel | ZG15, ZG20, ZG25, ZG35, ZG45, ZG55, Q235, Q345, Q420 | 1008, 1015, 1018, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1060, 1070, WC6, WCC, WCB, WCA, LCB | 1.0570, 1.0558, 1.1191, 1.0619, 1.0446, GS38, GS45, GS52, GS60, 1.0601, C20, C25, C30, C45 |

| Low Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V | 1117, 4130, 4140, 4340, 6150, 5140, WC6, LCB, Gr.13Q, 8620, 8625, 8630, 8640, H13 | GS20Mn5, GS15CrNi6, GS16MnCr5, GS25CrMo4V, GS42CrMo4, S50CrV4, 34CrNiMo6, 50CrMo4, G-X35CrMo17, 1.1131, 1.0037, 1.0122, 1.2162, 1.2542, 1.6511, 1.6523, 1.6580, 3, 2, 1.1. 1.7225, 1.7227, 1.7228, 1.7231, 1.7321, 1.8519, ST37, ST52 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Simbi | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

Cobalt-based alloy ialloy yakaoma inogona kumirisana nemhando dzakasiyana dzekupfeka, ngura uye yakanyanya tembiricha oxidation. Cobalt-based alloys yakavakirwa pacobalt sechinhu chikuru, iine huwandu hwakawanda hwenickel, alloying kemikari zvinhu zvakaita sechromium, tungsten uye chidimbu chidiki chealloying zvinhu zvakaita se molybdenum, niobium, tantalum, titanium, lanthanum, uye dzimwe nguva iron. . Zvinoenderana nekuumbwa kwakasiyana kweiyo alloy, iyo cobalt-based alloy inogona kugadzirwa kuita welding waya, uye hupfu hunogona kushandiswa kune yakaoma-pamusoro welding, kupfapfaidza kwemafuta, kupfapfaidza welding uye mamwe maitiro, uye inogona zvakare kugadzirwa kuita castings. , forgings uye poda metallurgy parts. Yakarongedzwa nemagumo ekushandiswa, cobalt-based alloys inogona kukamurwa kuita cobalt-based wear-resistant alloys, cobalt-based high-temperature alloys uye cobalt-based solution corrosion-resistant alloys. Mumamiriro ekushanda akajairwa, ese ari maviri asingapfeki uye anodzivirira tembiricha yakakwira kana kupfeka-inodzivirira uye inodzivirira corrosion. Mamwe mamiriro ekushanda angadawo kupisa kwakanyanya, kupfeka uye kusagadzikana kwemarara panguva imwe chete. Izvo zvakanyanya kuoma mamiriro ekushanda, zvakanyanya kujeka zvakanakira cobalt-based alloys.

Zvivakwa zveCobalt-Based Alloys

Iwo ma carbides mu cobalt-based superalloys ndeye MC, M23C6 uye M6C. Mune yakakandwa cobalt-based alloys, M23C6 inonaya pakati pezviyo miganhu uye dendrites panguva inononoka kutonhora. Mune mamwe alloys, iyo yakanaka M23C6 inogona kuumba eutectic ine matrix γ. MC carbide particles yakakura zvikuru kuti iite zvakananga kuva nemigumisiro inokosha pakuparadzanisa, saka kusimbisa simba pane alloy hakusi pachena, nepo carbides yakaparadzirwa zvakanaka ine simba rinosimbisa. Iyo carbides iri pamuganhu wezviyo (kunyanya M23C6) inogona kudzivirira kutsvedza kwemuganhu wezviyo, nokudaro kuvandudza simba rekutsungirira. Iyo microstructure ye cobalt-based superalloy HA-31 (X-40) inzvimbo yakapararira yekusimbisa (CoCrW) 6 C-mhando carbide. Iyo topological yakavharwa yakarongedzwa zvikamu zvinoonekwa mune mamwe cobalt-based alloys, senge sigma phase inokuvadza uye inoita kuti alloy brittle.

Iko kugadzikana kwekupisa kwecarbides mu cobalt-based alloys yakanaka. Kana tembiricha yakwira, mwero wekukura wekuunganidza carbide unononoka kupfuura mwero wekukura kwechikamu cheγ mune nickel-based alloy, uye tembiricha yekunyungudika zvakare mumatrix zvakare yakakwirira (kusvika 1100 ° C) . Naizvozvo, kana kutonhora kuchikwira, iyo cobalt-based alloy Simba reiyo alloy rinowanzo kuderera zvishoma nezvishoma. Cobalt-based alloys ane yakanaka yekupisa corrosion resistance. Chikonzero nei cobalt-based alloys ari nani kune nickel-based alloys mune izvi ndechekuti nzvimbo yekunyunguduka yecobalt sulfide (yakadai seCo-Co4S3 eutectic, 877 ℃) yakakwirira kupfuura iyo nickel ( Semuyenzaniso, Ni-Ni3S2 eutectic (645°C) yakakwirira, uye mwero wekupararira kwesarufa mucobalt wakadzikira zvakanyanya pane uya nickel. Uye nokuti akawanda e-cobalt-based alloys ane chromium yakakwirira kudarika nickel-based alloys, inogona kuumba chidziviriro chealkali metal sulfate (yakadai seCr2O3 inodzivirira iyo yakasvibiswa neNa2SO4) pamusoro pechigadziko , iyo oxidation kuramba kwecobalt-based alloys kazhinji yakadzikira pane iyo nickel-based alloys.

Yakasiyana kubva kune mamwe ma superalloys, cobalt-based superalloys haina kusimbiswa neyakarairwa mvura inonaya chikamu chakanyatso sungirirwa kune matrix, asi inoumbwa neaustenite fcc matrix iyo yakave yakasimba mhinduro yakasimbiswa uye shoma shoma yecarbides yakagoverwa mumatrix. Kukanda cobalt-based superalloys kunovimba zvakanyanya nekusimbisa carbide. Makristasi ecobalt akachena ane hexagonal close packed (hcp) crystal structure pazasi 417°C, inoshandura kuita fcc pakupisa kwepamusoro. Kuti udzivise shanduko iyi panguva yekushandiswa kwecobalt-based superalloys, anenge ese cobalt-based alloys anoiswa nickel kuitira kudzikamisa chimiro kubva mukamuri tembiricha kusvika pakunyungudika. Cobalt-based alloys ane flat fracture stress-temperature relationship, asi anoratidza kukwirira kupisa kwecorrosion resistance pane tembiricha iri pamusoro pe1000°C pane kumwe kupisa kwakanyanya.

Kupisa Kupisa kweCobalt-based Alloys

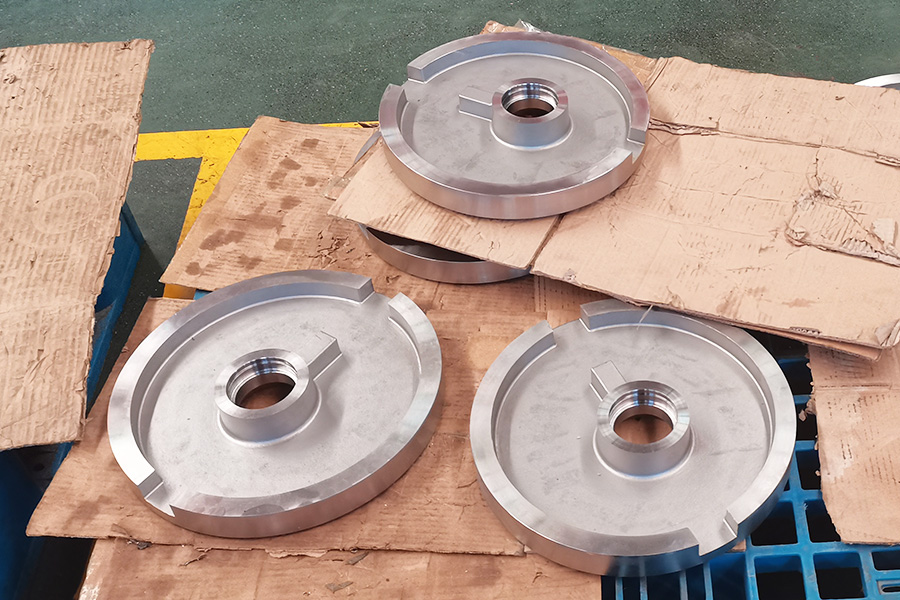

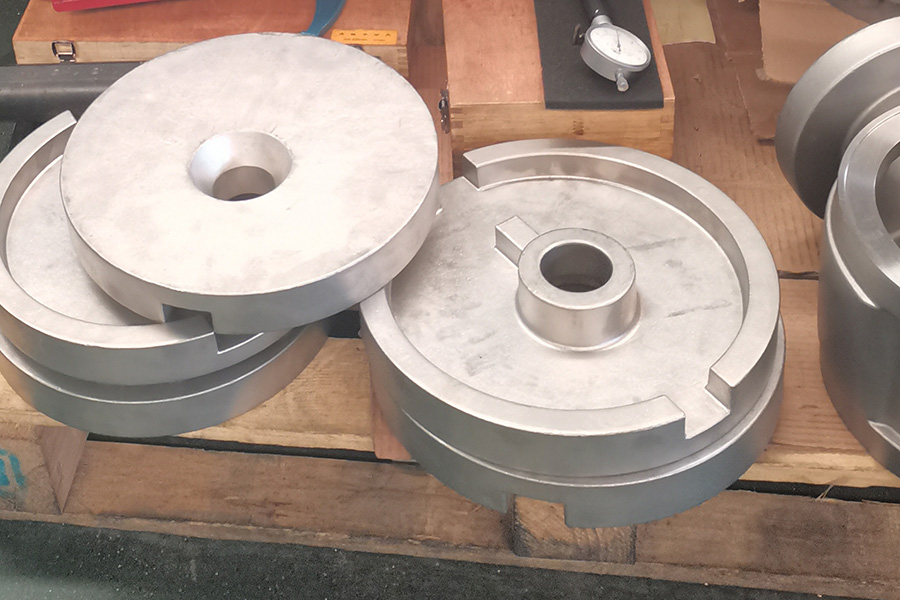

Saizi uye kugoverwa kwecarbide particles uye saizi yezviyo mucobalt-based alloys inotarisisa zvakanyanya pakukanda maitiro. Kuti uwane iyo inodiwa kutsungirira simba uye kupisa kuneta zvimiro zveakakanda cobalt-based alloy casting parts, iyo yekukanda maitiro paramita inofanirwa kudzorwa. Cobalt-based alloys inoda kurapwa kwekupisa, kunyanya kudzora kunaya kwecarbides. Kune akakanda cobalt-based alloys, tanga waita yakakwirira-tembiricha yakasimba mhinduro kurapwa, kazhinji pane tembiricha inosvika 1150 ° C, kuitira kuti ese ekutanga carbides, kusanganisira mamwe maMC-mhando carbides, anyungudiswe kuita yakasimba mhinduro; ipapo, kurapwa kwekuchembera kunoitwa pa870-980 ° C. Ita kuti carbides iwedzere zvakare.

Makirasi Akajairwa eCobalt-based Alloys

Iwo akajairwa mamakisi eyakajairwa cobalt-yakavakirwa yakakwirira tembiricha alloys ndeiyi: 2.4778 (maererano neDIN EN 10295)Hayness 188, Haynes 25 (L-605), Alloy S-816, UMCo-50, MP-159, FSX-414, X -40, Stellite 6B, Giredhi 31, nezvimwewo, mhando dzeChinese dzinoti: GH5188 (GH188), GH159, GH605, K640, DZ40M uye zvichingodaro.

Zvishandiso zveCobalt-based Alloy Castings

Kazhinji, cobalt-based superalloys inoshaya zvikamu zvekusimbisa. Kunyange zvazvo simba pakupisa kwepakati rakaderera (chete 50-75% ye nickel-based alloys), vane simba rakakwirira, kunaka kwekushisa kwekushisa kwekushisa, kusagadzikana kwebrasion, weldability zviri nani uye kupisa kwekushisa kwekushisa pamusoro petembiricha ye980 ° C. Naizvozvo, cobalt-based alloy castings inonyanya kukodzera kugadzira mavheti ekutungamira uye nozzle inotungamira vanes yeavhiyesheni jet injini, maindasitiri gasi turbines, naval gasi turbines, uye dizeli injini nozzles, nezvimwe.