Corrosion-resistant cast simbi, inonziwo cast Stainless simbi, inoreva simbi yakakandwa yealloy inoratidza kuramba kwakasimba mukuora mumhando dzakasiyana siyana dzinoparadza midhiya kana nharaunda inogara ngura nemakanika zvinhu.

| Kukurumidza Maonero eAustenitic Stainless Steel | |

| Main Chemical Composition | Cr,Ni,C,Mo,Cu,Si,Nb,Ti |

| Performance | Kwete-magnetic, kusimba kwepamusoro, purasitiki yakakwira, simba rakaderera |

| Tsanangudzo | Simbi isina tsvina ine austenitic chimiro pane tembiricha yekamuri |

| Representative Grades | 304, 316, 1.4310, 1.4301, 1.4408 |

| Machinability | Fair |

| Weldability | Kazhinji zvakanaka chaizvo |

| Mashandisiro Akajairika | Zvokudya michina, Hardwares, Chemical Processing ... nezvimwewo |

Simbi isina simbi ine hushoma hwe chromium inosvika 10.5%, zvichiita kuti isarambe iine corrosive liquid environments uye kuoxidation. Iyo inodzivirira zvakanyanya corrosion uye inopfeka inodzivirira, inopa yakanakisa machinability, uye inozivikanwa zvakanyanya nekutaridzika kwayo. Stainless simbi yekukandira mari "inodzivirira kupisa" kana ichishandiswa munzvimbo dzemvura uye mhute iri pasi pe1200°F (650°C) uye "inodzivirira kupisa" kana ichishandiswa pamusoro petembiricha iyi.

Austenitic simbi isina tsvinazvinoreva simbi isina tsvina ine austenitic chimiro patembiricha yekamuri. Austenitic Stainless simbi ndeimwe yemakirasi mashanu esimbi isina tsvina nekristaro chimiro (pamwe neferritic, martensitic, duplex uye kunaya kwakaoma). Mune dzimwe nzvimbo, iyo austentite simbi isina tsvina inonziwo 300 yakatevedzana Stainless simbi. Kana simbi ine inenge 18% Cr, 8% -25% Ni, uye inenge 0.1% C, ine yakagadzikana austenite chimiro. Austenitic chromium-nickel simbi isina tsvina inosanganisira yakakurumbira 18Cr-8Ni simbi uye yakakwira Cr-Ni yakatevedzana simbi yakagadziridzwa nekuwedzera Cr uye Ni zvemukati nekuwedzera Mo, Cu, Si, Nb, Ti uye zvimwe zvinhu pahwaro huno. Austenitic Stainless simbi haisi-magnetic uye ine yakakwirira kuoma uye plastiki, asi simba rayo rakaderera, uye hazvibviri kuisimbisa kuburikidza nechikamu chekushandura. Inogona chete kusimbiswa nekushanda kunotonhora. Kana zvinhu zvakaita seS, Ca, Se, Te zvawedzerwa, ine zvakanaka zvimiro zvemachinability.

Austenitic simbi isina tsvina inogonawo kugadzira castings. Kuti uvandudze kuyerera kwesimbi yakanyungudutswa uye kunatsiridza kuita kwekukanda, iyo alloy kuumbwa kwesimbi yakakandwa kunofanirwa kugadziridzwa nekuwedzera iyo silicon yemukati, kuwedzera huwandu hwechromium uye nickel zvemukati, uye kuwedzera muganho wepamusoro wechinhu chisina kuchena sarufa.

Austenitic Stainless simbi inofanirwa kuve yakasimba-solution yakabatwa isati yashandiswa, kuitira kuti iwedzere mhinduro yakasimba yezvakasiyana maprecipitates senge carbides musimbi mune austenite matrix, ukuwo homogenizing chimiro uye kubvisa kushushikana, kuitira kuve nechokwadi chakanakisa Corrosion kuramba uye mechanical properties. Iyo chaiyo mhinduro yekurapa sisitimu kutonhora kwemvura mushure mekudziya pa1050~1150 ℃ (zvikamu zvitete zvinogona zvakare kutonhodzwa nemhepo). Iyo tembiricha yekurapwa kwemhinduro inoenderana nedhigirii rekusanganiswa kwesimbi: Molybdenum-isina kana yakaderera-molybdenum simbi mamakisi anofanirwa kuve akaderera (≤1100 ℃), uye epamusoro alloyed mamakisi akadai 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, nezvimwewo inofanira kunge yakakwira ( 1080~1150) ℃).

Austenitic 304 Stainless simbi ndiro, iyo inonzi inounza yakasimba anti-ngura uye corrosion kuramba, uye ine yakanakisa plastiki uye kuoma, izvo zviri nyore kutsika nekugadzira. Iine density ye7.93 g/cm3, 304 Stainless simbi isimbi yakajairika, inozivikanwawo se 18/8 Stainless simbi muindasitiri. Zvigadzirwa zvayo zvesimbi zvinodzivirira kutonhora kwakanyanya uye zvine maitiro akanaka ekugadzirisa, saka anoshandiswa zvakanyanya mumaindasitiri uye fenicha yekushongedza maindasitiri uye chikafu nemishonga maindasitiri.

Yakaenzana Giredhi reStainless Simbi | |||||||

| Categories | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic uye Ferritic Stainless Simbi | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Stainless Simbi | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Simbi | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Ferrous and Non-ferrous Materials for Investment Casting, Yakarasika Wax Casting Process:

- • Simbi yeGrey: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • Ductile Iron kana Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

- • Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc pakukumbira.

- • Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 uye imwe giredhi yesimbi isina tsvina.

- • Brass, Red Copper, Bronze kana mamwe masimbi eCopper-based alloy: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Zvimwe Zvishandiso zvinoenderana nezvinodiwa zvako zvakasiyana kana zvinoenderana neASTM, SAE, AISI, ACI, DIN, EN, ISO, uye GB zviyero.

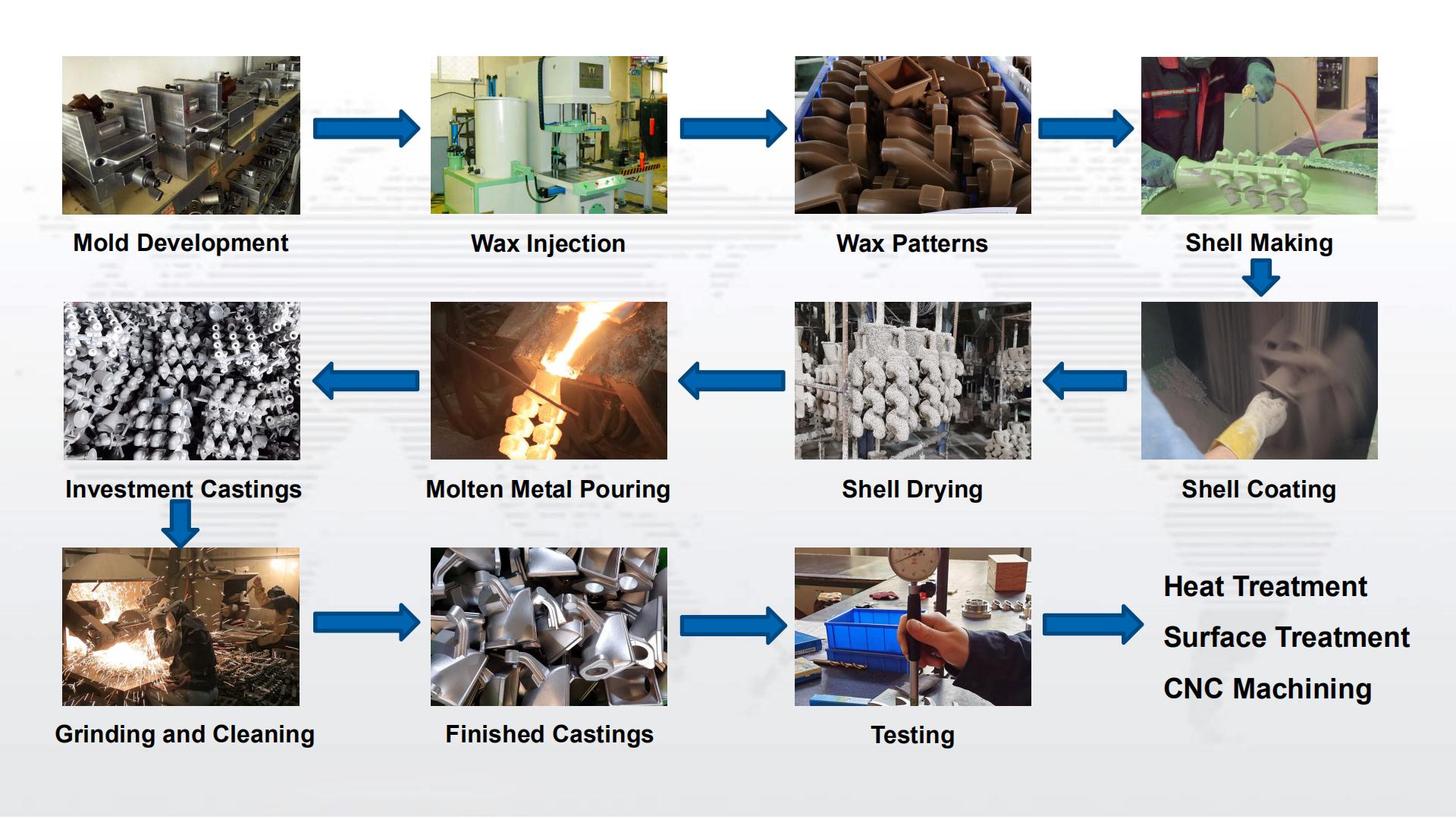

Matanho anowanikwa mukuita kana kurasika kukanda wakisi ndeaya:

- • Gadzira wax pattern kana replica

- • Paridza patani yewakisi

- • Isai patani yewakisi

- • Bvisa patani yewakisi nekuipisa (mukati mechoto kana mumvura inopisa) kugadzira mold.

- Kumanikidza kudira simbi yakanyungudutswa muforoma

- • Kutonhodza uye Kusimbisa

- • Bvisa sprue kubva pakukanda

- • Pedzisa uye kupukuta akapedzwa mari castings

Kupisa Kurapa kweAISI 316 Stainless Steel Castings:

Kupisa kusvika 1900°F (1040°C) kushoma, kubata kwenguva yakakwana, kudzima mumvura kana kutonhora nekukurumidza nedzimwe nzira. AISI 316 yakaenzana neCF8M/F316 uye Chinese Standard 0Cr17Ni12Mo2. AISI 314 ndeye molybdenum inobereka shanduko yeAISI 304 alloy uye ndiyo yakakandwa yakaenzana neyakagadzirwa CF8M Stainless simbi. Kuvapo kwe molybdenum kunowedzera kusimba kwekuora uye kuramba kwegomba nemakloridi. Iyo alloy inoshandiswa mune zvinyoro acidic uye alkaline mamiriro uye kubata citric, oxalic uye phosphoric acids.