Custom Aluminium alloy casting products byjecha kukanda nzirauyeCNC machining.

Matanho eJecha Kukandira Kugadzira Maitiro

1. Kuita Mapeteni

Resin kana aluminium mapatani ichave yakakosha kune yakasvibira jecha kukanda maitiro. Pasina mapatani, kugadzirwa kwekukanda hakuzogoneke. Dzimwe nguva, mapatani emapuranga anogona kushandiswa kugadzirwa kwehuwandu hudiki, asi pakugadzirwa kwakawanda, resin kana aluminium mapatani achave akakodzera.

2. Molding Process

Iyo yegirinhi jecha kuumba inogona kugadzirwa nenzira nhatu kazhinji, kusanganisira manyorero ekuumba, muchina wekuumba uye otomatiki kuumba michina. The manual molding inzira yechinyakare yekuumba, asi ichiripo nekuda kwekugona kwayo kukanda mahombe pamutengo wakaderera. Iyo yekuumba muchina nzira inogona kuchengetedza manpower uye kuburitsa zvirinani zvemhando yekukandira, asi haigone kuburitsa makuru ekukanda nekuda kwehukuru hwayo kudzikiswa kwemabhokisi ejecha.

3. Kunyunguduka kweSimbi uye Kudurura

Kunyunguduka kwaigona kuitwa nepakati frequency magetsi induction furnaces, izvo zvinogona kuchengetedza mhando yakanaka uye yakagadzikana kana ichienzaniswa neyechinyakare mavira.

4. Kuputika kwejecha uye Kukuya

Mushure mekunge simbi yejecha yakasvibirira yabviswa kubva muhuvhu hwejecha, inozoendeswa kune inotevera nhanho yekupfurwa kana kupfurwa kuti ibvise jecha uye oxide kunze kwezvikamu zvekukanda. Ipapo vashandi vachacheka, kuchenesa uye kukuya misoro yemagedhi, risers, mitsara yekuparadzanisa nemicheto yakapinza.

Kuenderera mberi nekugadzirisa senge kupisa kupisa, kunyatso gadzira uye kurapwa kwepamusoro kwaizoenderera mberi kana madhirowa kana ekupedzisira-vashandisi vachida.

Aluminium nema alloys ayo anogona kukandwa uye kudirwa nehigh pressure die casting, low pressure die casting, gravity casting, jecha kukanda, investment cast uye.kurasika furo. Kazhinji, iyo aluminium alloy castings ine huremu hushoma asi yakaoma kuumbwa uye nani pamusoro.

Iyo Aluminium Alloy Isu yatinokanda nejecha Kukandira Maitiro:

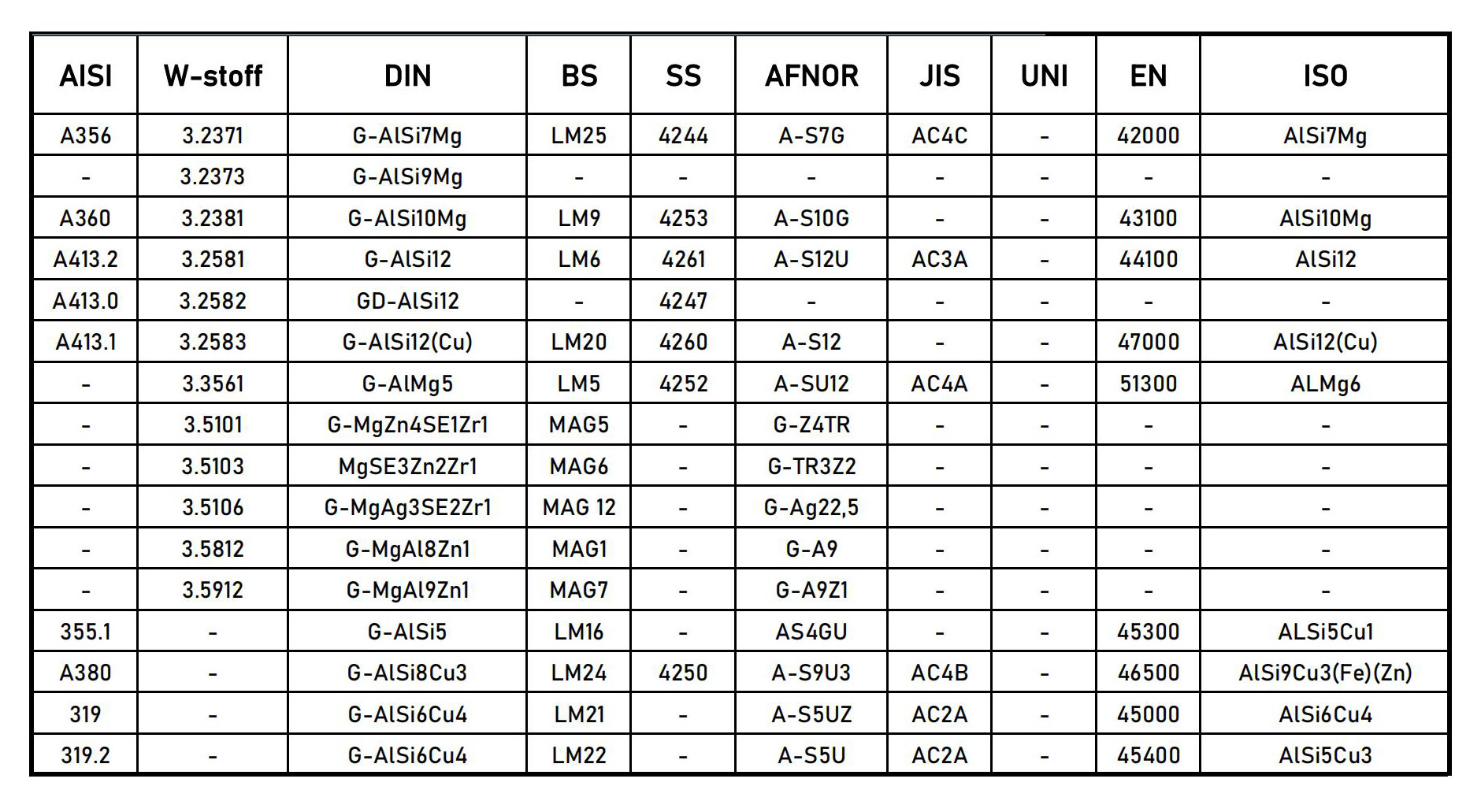

• Cast Aluminium Alloy neChina Standard: ZL101, ZL102, ZL104

• Cast Aluminium Alloy neUSA Stardard: ASTM A356, ASTM A413, ASTM A360

• Cast Aluminium Alloy nemamwe maStarndards: AC3A, AC4A, AC4C, G-AlSi7Mg, G-Al12

| Yakabatana | Aluminium association | Kuoma BHN | Ultimate tensile simba, MPa | Goho Simba, MPa | Modulus ye elasticity, GPa | Kuneta Simba, MPa |

| A03550 | AA355.0 | 75-105 | 255 | 185 | 70.3 | 69.0 |

| A03600 | AA360.0 | 75.0 | 300 | 170 | 71.0 | 138.0 |

| A03800 | AA380.0 | 80.0 | 317 | 159 | 71.0 | 138.0 |

| A03830 | AA383.0 | 75.0 | 310 | 152 | / | 145.0 |

| A03840 | AA384.0 | 85.0 | 331 | 165 | / | 140.0 |

| A03900 | AA390.0 | 120.0 | 280 | 240 | 81.2 | 140.0 |

| A04130 | AA413.0 | 80.0 | 296 | 145 | 71.0 | 130.0 |

| A04430 | AA443.0 | 30-60 | 145 | 48.3 | 71.0 | / |

| A05180 | AA518.0 | 80.0 | 310 | 193 | 69.0 | 160.0 |

Zvakanakira zveAluminium Alloy Castings:

• Kuita kwekukanda kwakafanana nekwesimbi, asi hukama hwemagetsi hunodzikira zvakanyanya sezvo ukobvu hwemadziro hunowedzera.

• Ukobvu hwemadziro ekukanda hahufanire kunge hwakanyanya kukura, uye zvimwe zvimiro zvakafanana neaya esimbi castings.

• Uremu hwakareruka asi chimiro chakaoma

• Mari yekukanda pakg yealuminium castings yakakwirira kudarika yesimbi nesimbi.

• Kana ikagadzirwa nedie casting process, mold uye pateni mutengo waizove wakakwira zvakanyanya kupfuura mamwe maitiro ekukanda. Naizvozvo, kufa casting aluminum castings kungave kwakakodzera kukanda kwehuwandu hunoda huwandu.

| Typical Chemical Composition ye Investment Casting Aluminium Alloy neNorth American Specifications | ||||||||||||||

| Alloy Grade | Tsanangudzo | Al | Cu | Si | Zn | Mg | Cr | Fe | Mn | Ti | Ag | Be | Ni | P |

| A356-T6 | AMS 4218 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.25-0.45 | - | 0.20 | 0.10 | 0.20 | - | -- | - | - |

| A 357 | AMS 4219 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.40-.70 | - | 0.20 | 0.10 | 0.04-0.20 | - | 0.04-0.07 | - | - |

| F 357 | AMS 4289 | Bal | 0.20 | 6.5-7.5 | 0.10 | 0.40-.70 | - | 0.10 | 0.10 | 0.04-0.20 | - | 0.002 | - | - |

| E 357 | AMS 4288 | Bal | - | 6.5-7.5 | 0.10 | 0.55-0.60 | - | 0.10 | 0.10 | 0.10-0.20 | - | 0.002 | - | - |

| A201 | AMS 4229 | Bal | 4.0-5.0 | 0.05 | - | 0.15-0.35 | - | 0.10 | 0.20-0.34 | 0.15-0.35 | 0.40-1.0 | - | - | - |

| C355 | AMS 4215 | Bal | 1.0-1.5 | 4.5-5.5 | 0.10 | 0.40-0.60 | - | 0.20 | 0.10max | 0.20 | - | - | - | - |

| A206 | AMS 4235 | Bal | 4.2-5.0 | .05max | 0.05max | 0.20-0.35 | - | 0.10ma | 0.20-0.50 | 0.15-0.30 | - | - | 0.5max | - |

| B206 | Bal | 4.2-5.0 | .05max | 0.05max | 0.15-0.35 | - | 0.10max | 0.20-0.50 | 0 10 | - | - | 0.5max | - | |