Tsika vharafu dzimba dze duplex Stainless simbi inogadzirwa neinvestment casting kubva kuChina casting foundry neMachining, kurapwa kwekupisa, uye mabasa ekurapa epamusoro.

RMC castprecision cast simbi zvikamuizvo zvinogara zvichisangana kana kudarika zvinotarisirwa nevatengi. Yakarasika wax investment casting inotibvumira kugadziraStainless simbi yekukanda zvigadzirwaidiki semakumi emagiramu uye yakakura semakumi emakirogiramu, mumhando dzakasiyana-siyana dzeferrous uye dzisina-ferrous alloys uye nekunyatso shamisa.

Iyo yakarasika yewakisi yekukandira maitiro inoburitsa pedyo-net-shape chaiyo castings iyo inowanzoda kushoma kana kusatowedzera machining. Mhedzisiro inoguma zvakare iri nani pane izvo zvinogoneka kuburikidza nekumwe kukanda kana kugadzira maitiro. Kusimba uye kusimba kwezvikamu zvekukanda zvinozviita zvakanakira kupfeka-resistance application inoda mamirioni ematenderedzwa.

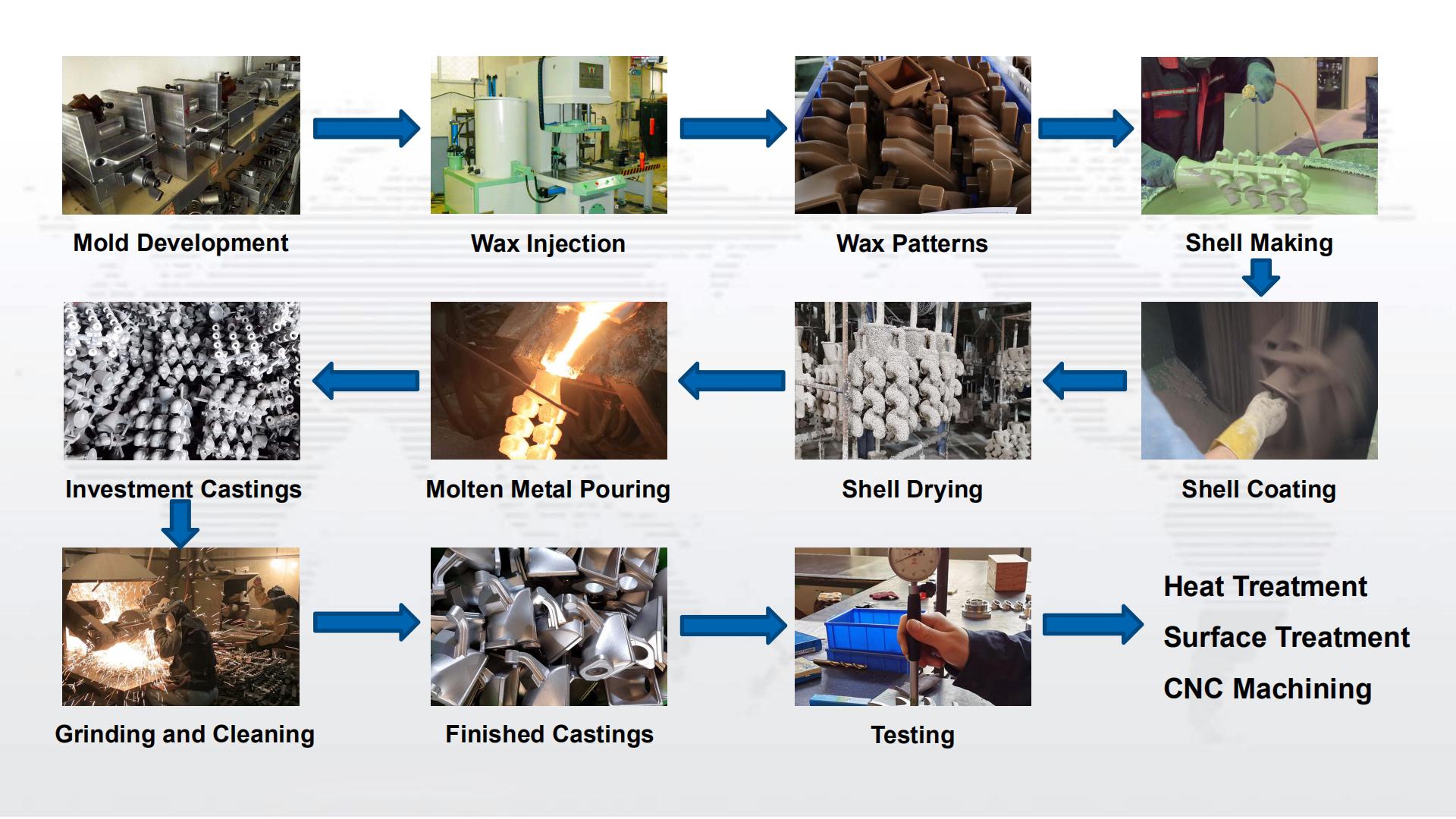

Matanho e Investment Casting process:

Munguva yekudyara kwekudyara maitiro, wax pateni inoputirwa neceramic material, iyo, kana yakaomeswa, inotora iyo yemukati geometry yekukanda yaunoda. Kazhinji, zvikamu zvakawanda zvinokandwa pamwechete kuti zvinyatsoshanda nekuisa mapatani ewakisi ega pachimuti chepakati chinonzi sprue. Wakisi inonyungudutswa kubva patani - ndokusaka ichizivikanwawo senzira yakarasika wakisi - uye simbi yakanyungudutswa inodirwa mugomba. Kana simbi yasimba, mold yeceramic inozununguswa, ichisiya chimiro chiri padyo chekukandwa kwaunoda, kuchiteverwa nekupedzisa, kuyedza uye kurongedza.

Duplex Stainless Steel (DSS) inoreva simbi isina tsvina ine ferrite uye austenite yega yega accounting inosvika 50%. Kazhinji, zviri mukati mezvikamu zvishoma zvinoda kuve zvishoma ne30%. Panyaya yezvakaderera C zvemukati, iyo Cr yemukati ndeye 18% kusvika 28%, uye iyo Ni yemukati ndeye 3% kusvika 10%. Mamwe duplex simbi isina tsvina zvakare ane alloying zvinhu zvakaita seMo, Cu, Nb, Ti, uye N.

Inowanikwa giredhi re duplex Stainless simbi paRMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890, A 08 A9 A8 A9A 890, 8 A9 A9 A9, 8 A9 A9 A9, 8 A9 A9 A9. 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

Iyo DSS ine hunhu hwe austenitic uye ferritic simbi isina tsvina. Kana ichienzaniswa neferrite, ine yakakwira plasticity uye ductility, hapana tembiricha yekamuri brittleness, uye yakanyanya kunatsiridza intergranular corrosion resistance uye welding performance, ichiri kuchengetedza brittleness, high thermal conductivity, uye superplasticity se ferrite simbi isina tsvina. Kuenzaniswa ne austenitic Stainless simbi, DSS ine simba rakawanda uye yakanyanya kunatsiridza kuramba kune intergranular corrosion uye chloride stress corrosion. Duplex simbi isina tsvina ine yakanakisa pitting corrosion resistance uye zvakare iri nickel-saving stainless simbi.

| Yakaenzana Giredhi reStainless Simbi | |||||||

| GROUPS | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic uye Ferritic Stainless Simbi | 420 C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Stainless Simbi | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Simbi | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Masimbi ane Ferrous uye Non-ferrous Metals forInvestment Casting, Yakarasika Wax Maitirwo ekukanda:

• Simbi yeGrey: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron kana Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc pakukumbira.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 uye imwe giredhi yesimbi isina tsvina.

• Brass, Red Copper, Bronze kana mamwe masimbi eCopper-based alloy: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Zvimwe Zvishandiso zvinoenderana nezvinodiwa zvako zvakasiyana kana zvinoenderana neASTM, SAE, AISI, ACI, DIN, EN, ISO, uye GB zviyero.

▶ Kugona kweInvestment Casting Foundry

• Kukura Kwepamusoro: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg - 100 kg

• Kwegore Kukwanisa: 2,000 matani

• Bond Materials for Shell Building: Silica Sol, Water Glass nemisanganiswa yawo.

| Services | Tsanangudzo |

| Surface Treatment Services | Powder Coating, Anodization, Electrophotesis, Chrome Plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, etc. |

| CNC Precision Machining Services | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Wire Electrode Cutting, Grinding...etc. |

| Kuongorora uye Kudzora Kwemhando | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Seal Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester ... nezvimwewo. |