OEM tsikaduplex simbi isina tsvina yakarasika kukanda wakisinekurapa kwekupisa, kurapwa kwepamusoro, CNC machining uye masevhisi ekuyedza kubva kune mumwe mutengesi muChina

RMC Foundry inokwanisa kuzadzisa zvakatemwa zvinoenderana neASTM, SAE, AISI, ACI, DIN, EN, ISO, GOST uye GB zviyero. Tine anopfuura zana akasiyana ferrous uye asiri-ferrous alloys ayo isu tinokandira zvikamu tichishandisa yakaoma dhizaini maitiro. Yedu dimensionally uye geometrically yakaomaInvestment castingsanogadzirwa kune mambure chimiro, kuderedza kudiwa kwechipiri machining.

Duplex Stainless Steel (DSS) inoreva simbi isina tsvina ine ferrite uye austenite yega yega accounting inosvika 50%. Kazhinji, zviri mukati mezvikamu zvishoma zvinoda kuve zvishoma ne30%. Panyaya yezvakaderera C zvemukati, iyo Cr yemukati ndeye 18% kusvika 28%, uye iyo Ni yemukati ndeye 3% kusvika 10%. Mamwe duplex simbi isina tsvina zvakare ane alloying zvinhu zvakaita seMo, Cu, Nb, Ti, uye N.

Iyo DSS ine hunhu hwe austenitic uye ferritic simbi isina tsvina. Kana ichienzaniswa neferrite, ine yakakwira plasticity uye ductility, hapana tembiricha yekamuri brittleness, uye yakanyanya kunatsiridza intergranular corrosion resistance uye welding performance, ichiri kuchengetedza brittleness, high thermal conductivity, uye superplasticity se ferrite simbi isina tsvina.

Kuenzaniswa ne austenitic Stainless simbi, DSS ine simba rakawanda uye yakanyanya kunatsiridza kuramba kune intergranular corrosion uye chloride stress corrosion. Duplex simbi isina tsvina ine yakanakisa pitting corrosion resistance uye zvakare iri nickel-saving stainless simbi.

Yedu yepamusoro-ye-ye-mutsara michina uye otomatiki maitiro ekudzora anobvumira kunoenderana uye kudzokororwa kushivirira padyo se ± 0.1 mm. Zvikamu zvedu zvinogonawo kugadzirwa muhukuru hwakakura-zvinogona kunge zviduku se 10 mm kureba x 10 mm pahupamhi x 10 mm kureba uye huremu hushoma se0.01 kg, kana kuti hurefu hunosvika 1000 mm uye huremu hwakafanana. 100 kg.

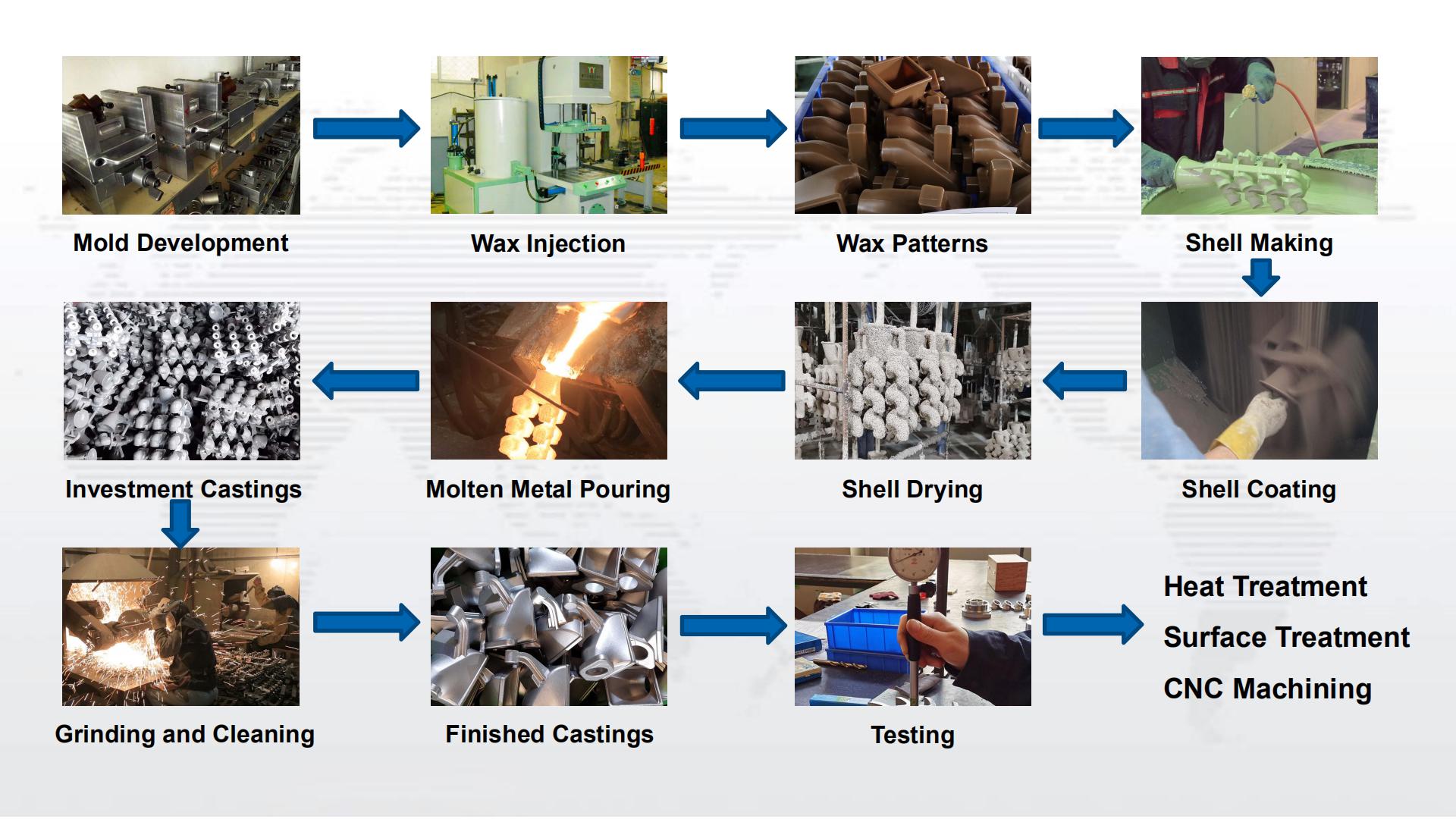

PaRMC Foundry, tinodada nekupa vatengi vedu sevhisi yepamusoro-soro kubva pakutanga kusvika pakupedzisira. Masevhisi edu anosanganisira:

- - In-house tooling dhizaini uye kugona kugadzira.

- - Prototype kuvandudzwa.

- - Maitiro ekutsvagisa nekusimudzira.

- -Kugadzira kuchinjika.

- -Kufanirwa uye kuyedzwa.

- - Kupisa Kurapa

- - Surface Treatment

- - Outsourcing Manufacturing kugona