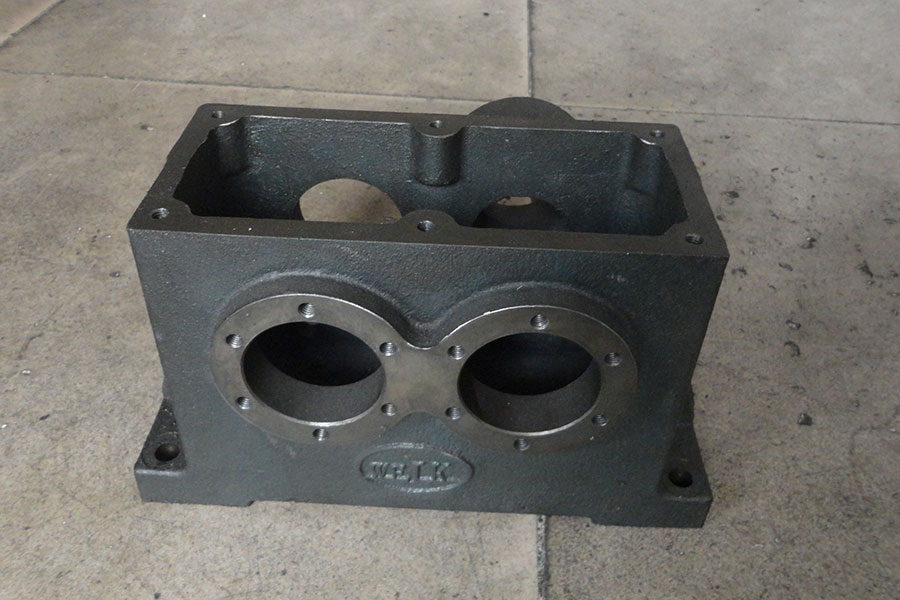

Gray cast iron products byjecha mold casting processuye CNC machining.

Grey cast iron inotumidzwa zita regrey ruvara rwekutsemuka kwainoumba. Iyo grey cast iron inoshandiswa kune dzimba uko kuomarara kwechikamu kwakakosha kupfuura simba rayo rekusimba, senge mukati meinjini inopisa silinda zvidhinha, pombi dzimba, miviri yevharuvhu, mabhokisi emagetsi, zviremu zve counter uye zvekushongedza castings. Grey cast iron's high thermal conductivity uye chaiyo musoro kugona kunowanzo shandiswa kugadzira cast iron cookware uye disc brake rotors.

Yakajairika kemikari kuumbwa kuwana graphic microstructure ndeye 2.5 kusvika 4.0% kabhoni uye 1 kusvika 3% silicon nehuremu. Graphite inogona kutora 6 kusvika 10% yehuwandu hwegrey iron. Sirikoni inokosha pakuita grey iron inopesana nesimbi yakachena yakakandwa, nokuti silicon isimbi inogadzirisa girafu musimbi yakakandwa, zvinoreva kuti inobatsira iyo alloy kubudisa graphite panzvimbo yesimbi carbides; pa 3% silicon inenge isina kabhoni inobatwa mumakemikari akabatanidzwa nesimbi.

Iyo graphite inotora chimiro chetatu-dimensional flake. Mumativi maviri, senzvimbo yakakwenenzverwa ichaonekwa pasi pemaikorosikopu, ma graphite flakes anoita semitsetse yakanaka. Iwo matipi emaflakes anoshanda seasati avapo notches; saka, ine brittle. Kuvepo kwema graphite flakes kunoita kuti Grey Iron iite nyore machina sezvo ichida kutsemuka zviri nyore kuyambuka ma graphite flakes. Grey iron zvakare ine yakanaka kwazvo yekunyorovesa simba uye nekudaro inonyanya kushandiswa sehwaro hwemakina ekumisikidza.

Grey Cast Iron Mechanical Properties | |||||||

| Chinhu zvinoenderana neDIN EN 1561 | Kuyera | Unit | SH-GJL-150 | EN-GJL-200 | SH-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Tensile Simba | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Goho Simba | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Elongation Simba | A | % | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 |

| Compressive Strength | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Compressive Strength | pd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural Strength | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Modules ye elasticity | E | GPa | 78 - 103 | 88 – 113 | 103 – 118 | 108 – 137 | 123 - 143 |

| Poisson nhamba | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Brinell kuoma | HB | 160 - 190 | 180 - 220 | 190 - 230 | 200 - 240 | 210 - 250 | |

| Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Tension uye kumanikidzwa kuchinja | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Kuputsa Simba | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Density | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Kukanda jecha kunoshandisa jecha rakasvibira (jecha rakanyorova) kana jecha rakaoma kugadzira masisitimu ekuumba. Kukandwa kwejecha regirini ndiyo nzira yekare yekukanda yakashandiswa munhoroondo. Paunenge uchigadzira mold, maitiro akagadzirwa nematanda kana simbi anofanirwa kugadzirwa kuitira kuti agadzire gomba regomba. Simbi yakanyungudutswa inozodira mugomba kuti iite zvinokandwa mushure mekutonhodzwa nekuoma. Kukanda jecha kunodhura pane mamwe maitiro ekukanda ese ekuvandudza mold uye unit yekukanda chikamu. Kukanda jecha, nguva dzose zvinoreva kukanda jecha regirini (kana pasina tsananguro yakakosha). Nekudaro, mazuva ano, mamwe maitiro ekukanda ari kushandisawo jecha kugadzira mold. Vane mazita avo, sekutishell mold casting, furan resin yakavharwa jecha kukanda (hapana mhando yekubika),kurasika furouye vacuum casting.

Jecha Kukandira Kugona paRMC Foundry | ||

| Tsanangudzo | Molding by Manual | Kuumbwa neAutomatic Machines |

| Hukuru hweCastings | 1,500 mm × 1000 mm × 500 mm | 1,000 mm × 800 mm × 500 mm |

| Kukanda Weight Range | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

| Annual Capacity | 5,000 matani - 6,000 matani | 8,000 matani - 10,000 matani |

| Casting Tolerance | Pachikumbiro kana Standard (ISO8062-2013 kana GB/T 6414-1999) | |

| Molding Materials | Green Sand, Resin Yakavharwa jecha | |

| Kukanda Metal & Alloys | Grey Iron, Ductile Iron, Cast Steel, Stainless Steel, Al Alloys, Brass, Bronze...etc. | |

Zvakanakira zveSand Casting:

- ✔ Mutengo Wakaderera nekuda kwezvakachipa uye zvinodzokororwa mold zvinhu uye zviri nyore kugadzira michina.

- ✔ Huwandu hwehuremu hweyuniti kubva pa0.10 kg kusvika pa500 kgs kana kutokura.

- ✔ Yakasiyana Mamiriro kubva kumhando yakapusa kuenda kune yakaoma mhando.

- ✔ Inokodzera kugadzirwa kwezvinodiwa zvehuwandu hwakasiyana.

Kushivirira Kuti Jecha Castings Ibudirire:

Iyo yekukanda kushivirira yakakamurwa kuva Dimensional Casting Tolerances (DCT) uye Geometrical Casting Tolerances (GCT). Yedu yekutanga inoda kutaura newe kana uine chikumbiro chakakosha pane zvinodiwa kushivirira. Pano mune zvinotevera giredhi rekushivirira rataigona kusvika nekukandira jecha redu rakasvibira, kukanda ganda mold uye kwete-kubika furan resin jecha kukanda:

- ✔ DCT Giredhi neGreen Sand Casting: CTG10 ~ CTG13

- ✔ DCT Giredhi neShell Mold Kukanda kana Furan Resin Jecha Kukandira: CTG8 ~ CTG12

- ✔ GCT Giredhi neGreen Sand Casting: CTG6 ~ CTG8

- ✔ GCT Giredhi neShell Mold Kukanda kana Furan Resin Jecha Kukandira: CTG4 ~ CTG7

Metal & Alloys Giredhi yeJecha Kukandira Maitiro | |

| Metal & Alloys | Popular Giredhi |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodualar) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | SH-GJS-800-8, SH-GJS-1000-5, SH-GJS-1200-2 |

| Carbon Steel | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Simbi isina ngura | Ferritic Stainless Simbi, Martensitic Stainless Simbi, Austenitic Stainless Simbi, Kunaya Kuomesa Stainless Simbi, Duplex Stainless Simbi |

| Aluminium Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Brass / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, uye GB | |

-

Grey Cast Iron Sand Kukanda Chigadzirwa

-

Grey Cast Iron Shell Inokanda Chigadzirwa

-

OEM Gray Kukanda Iron Kukanda

-

Alloy Steel Resin Yakaputirwa Jecha Kukandira Crankshaft

-

Alloy Steel Sand Castings

-

Alloy Steel Rori Zvikamu neSand Casting uye CNC...

-

Carbon Steel Sand Casting Company

-

Kanda Steel Sand Kukanda

-

Aluminium Alloy Sand Kukanda