Industrial electrocoating inoshandiswa zvakanyanya pamusoro pekurapa kudzivirira iyometal castingsuye CNC machining zvigadzirwa kubva mukuora nekupera kwakanaka. Vatengi vakawanda vanobvunza mibvunzo pamusoro pepamusoro kurapwa kwesimbi castings uyeprecision machined zvikamu. Ichi chinyorwa chichatarisa pane electrophoretic coating process. Ndinovimba zvichabatsira kune vese vanobatana.

Electrocoating inzira yekupfekedza iyo zvidimbu zvakaita se pigment uye resin zvakaturikwa mu electrophoretic solution zvinonangidzirwa kuti zvifambe uye kuisa pamusoro peimwe yemagetsi nekushandisa kunze kwemagetsi munda. Nheyo ye electrophoretic coating yakagadzirwa pakupera kwema1930, asi iyi tekinoroji yakagadziridzwa uye yakawana kushandiswa kwemaindasitiri mushure me 1963. Electrophoretic coating ndiyo inonyanya kushanda nzira yekuvaka yemvura-based coatings. Electrophoretic coating ine hunhu hwekunyungudika kwemvura, kwete-chepfu, uye nyore otomatiki kudzora. Nekuti inokodzera kurapwa kwepamusoro kweanoita conductive workpieces (simbi castings, muchina zvikamu, forgings, sheet simbi zvikamu uye welding zvikamu, nezvimwewo), iyo electrophoretic coating process yakakurumidza kushandiswa zvakanyanya mumaindasitiri senge mota, zvekuvakisa, hardware. , uye midziyo yemumba.

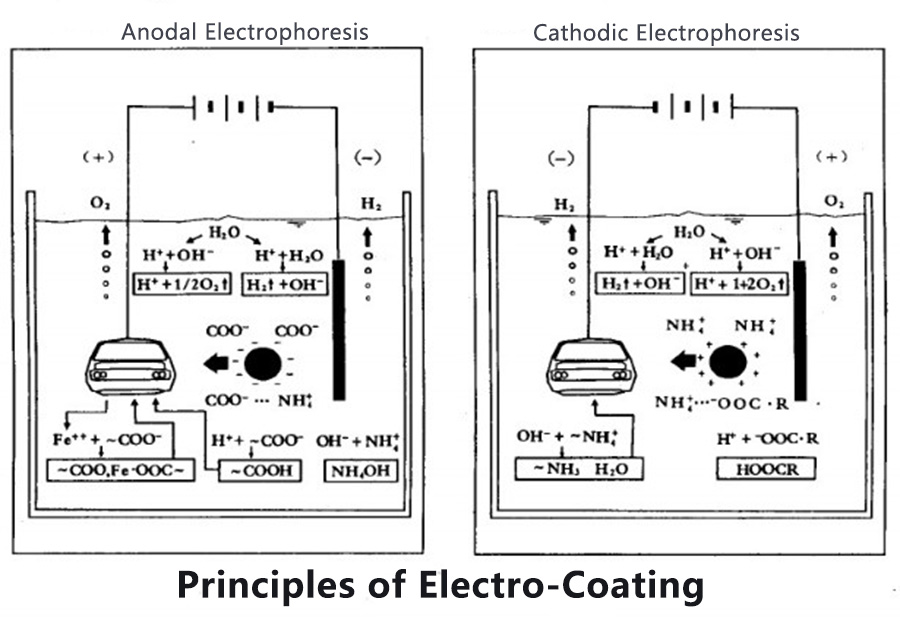

Mitemo

Iyo resin iri mu cathodic electrophoretic coating ine mapoka ekutanga, ayo anoumba munyu mushure mekusagadzikana kweasidhi uye kunyungudika mumvura. Mushure mekunge iyo yakananga ikozvino yaiswa, iyo asidhi yakanyanya kunaka ion inofamba ichienda kune anode, uye resin ion uye pigment particles akaputirwa nawo anoenda kune cathode nechaji yakanaka uye anoiswa pane cathode. Uyu ndiwo musimboti wekutanga we electrophoretic coating (inowanzozivikanwa seplating). Electrophoresis coating is a very complex electrochemical reaction, angangoita mana mhedzisiro ye electrophoresis, electrodeposition, electrolysis, uye electroosmosis zvinoitika panguva imwe chete.

Electrophoresis

Mushure mekunge anode uye cathode mu colloidal solution yaiswa simba, iyo colloidal particles inoenda kune cathode (kana anode) pasi pechiito chemunda wemagetsi, unonzi electrophoresis. Chinhu chiri mucolloidal solution hachisi muchimiro chemamorekuru nemaion, asi solute yakaparadzirwa mumvura. Mushonga wacho wakakura uye haungadhuri kuita nzvimbo yakapararira.

Electrodeposition

Chiitiko chekunaya kwakasimba kubva mumvura inonzi agglomeration (agglomeration, deposition), iyo inowanzo gadzirwa kana kutonhora kana kuisa pfungwa pamhinduro, uye electrophoretic coating inovimba nemagetsi. Mu cathodic electrophoretic coating, zvakanaka chaji particles aggregate pane cathode, uye zvakaipa chaji zvimedu (kureva ions) aggregate pane anode. Kana iyo colloidal particles yakachajiswa zvakanaka (resin uye pigment) inosvika pacathode (substrate) Mushure menzvimbo yepamusoro (yakanyanya alkaline interface layer), maerekitironi anowanikwa uye anopindirana neiyo hydroxide ion kuti ive mvura-insoluble zvinhu, izvo zvinoiswa pane cathode ( pendi workpiece).

Electrolysis

Mune mhinduro ine ionic conductivity, iyo anode uye cathode yakabatana kune yakananga ikozvino, anions inokwezvwa kune anode, uye cations inokwezvwa kune cathode, uye kemikari reaction inoitika. Iyo anode inogadzira simbi yakanyungudika uye electrolytic oxidation kuti ibudise okisijeni, chlorine, nezvimwe. Iyo anode i electrode inogona kuburitsa oxidation reaction. Iyo simbi inonaya pane cathode uye H + inoderedzwa nemagetsi kuita haidrojeni.

Electroosmosis

Mushure mokunge migumo miviri (cathode uye anode) yezvigadziriso zvine maitiro akasiyana-siyana akaparadzaniswa ne semipermeable membrane inosimbiswa, chiitiko chokuti pasi-concentration solution inoenda kudivi repamusoro-soro rinonzi electroosmosis. Firimu rekuputira rakangoiswa pamusoro pechinhu chakaputirwa ifirimu rinogoneka. Pasi pechiito chinoramba chiripo chemunda wemagetsi, mvura iri muine smearing film dialysis kubva mufirimu uye inofamba ichienda kubhati kuti isvibise firimu. Izvi zvinonzi electroosmosis. Electroosmosis inoshandura iyo hydrophilic coating firimu kuita hydrophobic coating firimu, uye kupera simba kunoita kuti firimu rekuputira rideredze. Iyo pendi yakanyorova mushure mekushambira ine yakanaka electro-osmosis electrophoretic pendi inogona kubatwa uye kwete kunamatira. Iwe unogona kugezesa mvura yekugezesa uchinamatira kune yakanyorova pendi firimu nemvura.

Hunhu hweElectrocoating

Electrophoretic pendi firimu ine zvakanakira kuzara, kufanana, flatness uye yakatsetseka coating. Iko kuomarara, kunamatira, corrosion kuramba, maitiro ekuita, uye kupera kwe electrophoretic pendi firimu zviri nani pane mamwe maitiro ekuputira.

(1) Pendi inonyungudika yemvura inoshandiswa, mvura inoshandiswa seyakanyungudika, inochengetedza yakawanda organic solvents, inoderedza zvakanyanya kusvibiswa kwemhepo uye njodzi dzezvakatipoteredza, yakachengeteka uye yakachena, uye inodzivirira njodzi yakavanzika yemoto;

(2) Kushanda kwependi kwakakwira, kurasikirwa kwepende kudiki, uye chiyero chekushandisa pendi chinogona kusvika 90% kusvika 95%;

(3) Ukobvu hwefirimu hwekuputira hwakafanana, kunamatira kwakasimba, uye kunaka kwekupfeka kwakanaka. Chikamu chega chega chebasa, senge yemukati layer, depressions, welds, nezvimwewo, inogona kuwana yunifomu uye yakatsetseka yekuputira firimu, iyo inogadzirisa dambudziko reimwe nzira yekuputira yezvakaoma-shaped workpieces. Dambudziko rekupenda;

(4) Kubudirira kwekugadzira kwakakwira, uye chivakwa chinogona kuona otomatiki uye kuenderera kugadzirwa, izvo zvinovandudza zvakanyanya kushanda zvakanaka;

(5) Midziyo yakaoma, mari yekudyara yakakwira, mashandisirwo emagetsi akakura, tembiricha inodiwa pakuomeswa nekurapa yakakwira, manejimendi ependi nependi yakaoma, mamiriro ekuvaka akaomarara, uye kuchenesa mvura yetsvina kunodiwa. ;

(6) Pendi inonyungudika chete nemvura inogona kushandiswa, uye ruvara harungachinji panguva yekuputira. Kugadzikana kwepende hakusi nyore kudzora mushure mekuchengetedza kwenguva yakareba.

(7) Iyo electrophoretic coating midziyo yakaoma uye tekinoroji yemukati yakakwira, iyo yakakodzera kugadzirwa kwemavara akaiswa.

Kuganhurirwa kweElectrocoating

(1) Inokodzera chete kupfekwa kweprimer ye conductive substrates senge muchina zvikamu zve ferrous simbi uye non-ferrous simbi. Zvinhu zvisina-conductive zvakadai sehuni, plastiki, jira, nezvimwewo hazvigoni kuputirwa nenzira iyi.

(2) Electrophoretic coating process haina kukodzera kune zvakavharwa zvinhu zvinoumbwa nesimbi dzakawanda, kana maitiro e electrophoresis akasiyana.

(3) Electrophoretic coating process haigone kushandiswa kune zvakavharwa zvinhu izvo zvisingakwanisi kumira kupisa kwakanyanya.

(4) Electrophoretic coating haina kukodzera kupfekedza nezvinodiwa zvishoma pane ruvara. Electrophoretic coating yemavara akasiyana inoda kupendwa muma grooves akasiyana.

(5) Electrophoretic coating haikurudzirwe kune diki-batch kugadzirwa (nguva yekuvandudza yekugezera inopfuura mwedzi mitanhatu), nekuti kukurumidza kwekuvandudza kwekugeza kunonoka, resin mubhavhu iri kuchembera uye zvinonyungudutsa zvinoshanduka. zvikuru. Bhati harina kugadzikana.

Matanho eElectrocoating

(1) Kune electrophoretic coating of general metal surfaces, process flow is: pre-cleasing → degreasing → kugeza mvura → kubvisa ngura → kugeza mvura → neutralization → kugeza mvura → phosphating → kugeza mvura → passivation → electrophoretic coating → tank top Kuchenesa → ultrafiltration mvura yekugeza → kuomesa → isina online.

(2) Iyo substrate uye pretreatment yechinhu chakaputirwa chine simba guru pane electrophoretic coating film. Masimbi anokandwa anowanzo kucheneswa nejecha kana kuputika kuputika, shinda yedonje inoshandiswa kubvisa guruva rinoyangarara pamusoro pechishandiso, uye sandpaper inoshandiswa kubvisa zvakasara zvesimbi pfuti uye humwe marara pamusoro. Iyo simbi yepamusoro inobatwa ne degreasing uye kubvisa ngura. Kana izvo zvinodikanwa zvepasi zvanyanya, phosphating uye passivation pamusoro pekurapa inodiwa. Ferrous metal workpieces inofanira kuva phosphated pamberi pe anodic electrophoresis, kana zvisina kudaro kupikisa kwekuora kwefirimu yependi kuchave kusina kunaka. Mukurapa phosphating, zinc munyu phosphating firimu rinowanzo kusarudzwa, nehupamhi hunosvika 1 kusvika 2 μm, uye iyo phosphate firimu inodiwa kuti ive yakanaka uye yakafanana makristasi.

(3) Mune yekusefa system, iyo yekutanga kusefa inowanzo gamuchirwa, uye sefa ndeye mesh bag chimiro. Pendi ye electrophoretic inotakurwa kuenda kusefa kuburikidza nepombi yakatwasuka yekusefa. Tichifunga nezve yakazara yekutsiva kutenderera uye kunaka kwefirimu repende, bhegi resefa rine saizi yepore ye50μm ndiyo yakanyanya kunaka. Haikwanise kuzadzisa zvinodiwa zvemhando yependi firimu, asi zvakare kugadzirisa dambudziko rekuvhara bag refirita.

(4) Kukura kwemaitiro ekutenderera kwe electrophoretic coating kunobata zvakananga kugadzikana kwekugezera uye kunaka kwefirimu yepende. Kuwedzera kutenderera kwevhoriyamu kunoderedza kunaya uye mabhubhu emvura yekugezesa; zvisinei, kuchembera kwemvura yekugeza kunowedzera, kushandiswa kwesimba kunowedzera, uye kugadzikana kwemvura yekugeza kunowedzera kuipa. Izvo zvakanaka kudzora nguva dzekutenderera kwetangi mvura kusvika 6-8 nguva / h, iyo isingangotsigire kunaka kwefirimu repende, asiwo inovimbisa kushanda kwakagadzikana kwetangi mvura.

(5) Sezvo nguva yekugadzira ichiwedzera, iyo impedance yeanode diaphragm inowedzera uye inoshanda inoshanda voltage inoderera. Naizvozvo, mukugadzira, magetsi ekushandisa emagetsi anofanirwa kuwedzerwa zvishoma nezvishoma zvichienderana nekurasikirwa kwemagetsi kutsiva kudonha kwevoltage yeanode diaphragm.

(6) Iyo ultrafiltration system inodzora kusanganiswa kweiyoni yekusachena yakaunzwa neiyo workpiece kuve nechokwadi chemhando yekupfeka. Mukushanda kwegadziriro iyi, zvinofanirwa kucherechedzwa kuti kana hurongwa hwave kushanda, hunofanirwa kuenderera mberi uye hunorambidzwa zvachose kumhanya nguva nenguva kudzivirira iyo ultrafiltration membrane kubva pakuoma. Iyo yakaomeswa resin uye pigment inonamatira kune ultrafiltration membrane uye haigone kucheneswa zvakakwana, izvo zvinokanganisa zvakanyanya kupenya kwemvura uye hupenyu hwebasa hweiyo ultrafiltration membrane. Kubuda kwemvura kweyero ye ultrafiltration membrane inoratidza kuderera kwemaitiro nenguva yekumhanya. Inofanira kucheneswa kamwe chete kwemazuva 30-40 ebasa rinoramba richiitwa kuti ive nechokwadi chemvura ye ultrafiltration inodiwa kune ultrafiltration leaching uye kushambidza.

(7) Iyo electrophoretic coating method inokodzera kugadzirwa kwehuwandu hwemagungano mitsara. Iyo yekuvandudza kutenderera kweiyo electrophoresis bath inofanira kunge iri mukati memwedzi mitatu. Iyo yesainzi manejimendi yekugezera yakakosha zvakanyanya. Zvikamu zvakasiyana-siyana zvekugezera zvinoongororwa nguva dzose, uye bhati rinogadziriswa uye rinotsiviwa maererano nemigumisiro yekuedza. Kazhinji, maparamendi emushonga wekugezesa anoyerwa pane inotevera frequency: iyo pH kukosha, yakasimba yemukati uye conductivity yemhinduro ye electrophoresis, ultrafiltration solution uye ultrafiltration yekuchenesa mhinduro, anion (anode) polar solution, circulating lotion, uye deionization yekuchenesa mhinduro kamwe chete. zuva; Base ratio, organic solvent zvemukati, uye marabhoritari diki tangi bvunzo kaviri pasvondo.

(8) Pakutarisira kunaka kwefirimu repende, kufanana uye kukora kwefirimu repende kunofanirwa kuongororwa nguva nenguva, uye chitarisiko hachifanirwe kunge chine mapini, sagging, orange peel, wrinkles, nezvimwe. Gara uchitarisa muviri nemakemikari zviratidzo zvakadai sekunamatira uye corrosion resistance yefirimu yekuputira. Kutenderera kwekuongorora kunoenderana nezviyero zvemugadziri wekuongorora, uye kazhinji batch yega yega inoda kuongororwa.

Kurapa Kwepamusoro Pamberi peElectrophoresis

Iko kurapwa kwepamusoro kweiyo workpiece isati yapfekedzwa chikamu chakakosha che electrophoretic coating, kunyanya inosanganisira degreasing, kubvisa ngura, kugadzirisa kwepamusoro, phosphating uye mamwe maitiro. Unhu hwekurapa kwayo hausi kungokanganisa kutaridzika kwefirimu, kunoderedza kushanda kwe-anti-corrosion, asiwo kunoparadza kugadzikana kwependi mhinduro. Naizvozvo, pamusoro peiyo workpiece isati yapenda, inodikanwa kuti ive isina mavara emafuta, mavanga emarara, pasina pretreatment makemikari uye phosphating sedimentation, nezvimwewo, uye iyo phosphating firimu ine dense uye yunifomu makristasi. Nezve nzira dzakasiyana dzekurapwa kusati kwaitwa, isu hatizozvikurukure mumwe nemumwe, asi tinongoisa pamberi mashoma mapoinzi ekutarisisa:

1) Kana iyo inodonha uye ngura isina kuchena, haizongokanganisa kuumbwa kwephosphating firimu, asi zvakare inokanganisa kusungirirwa kwesimba, kushongedza kwekuita uye kushomeka kwekupokana kwejasi. Iyo firimu yepende inowanzoita shrinkage uye pinholes.

2) Phosphating: Chinangwa ndechekuvandudza kunamatira uye anti-corrosion kugona kweiyo electrophoretic firimu. Basa rayo nderekutevera:

(1) Nekuda kwemhedzisiro yemuviri uye yemakemikari, kunamatira kweiyo organic coating firimu kune substrate kunowedzerwa.

(2) Iyo phosphating firimu inoshandura iyo simbi yepasi kubva kune yakanaka conductor kuenda kune murombo conductor, nekudaro ichivharira kuumbwa kwemabhatiri-mabhatiri pamusoro pesimbi, zvichidzivirira kudzivirira kukora kwejasi, uye kuwedzera kusimba kwekuora uye kuramba kwemvura kweiyo. coating. Mukuwedzera, chete pamusana pekunyatsodzika pasi uye kuderedza, firimu inogutsa yephosphating inogona kuumbwa panzvimbo yakachena, yunifomu, uye isina mafuta. Kubva pachinhu ichi, iyo phosphating firimu pachayo ndiyo yakanyanya intuitive uye yakavimbika yekuzvitarisa pamhedzisiro ye pretreatment process.

3) Kushamba: Hunhu hwekugezesa pane imwe neimwe nhanho yekutangisa huchave nepesvedzero huru pahutano hwese pretreatment uye pendi firimu. Yekupedzisira deionized mvura kuchenesa pamberi pekupenda, ita shuwa kuti kudonha conductivity yechinhu chakavharwa haisi mukuru kupfuura 30μs/cm. Iyo yekuchenesa haina kuchena, senge workpiece:

(1) Residual acid, phosphating chemical liquid, flocculation yeresin mumvura yependi, uye kuderera kwekugadzikana;

(2) Zvakasara kunze kwenyika (mafuta mavara, guruva), shrinkage makomba, zvimedu uye zvimwe kukanganisa mufirimu repende;

(3) Kusara kwe electrolytes nemunyu zvinotungamira mukuwedzeredza kwe electrolysis reaction uye kuburitsa pinholes uye mamwe marasha.

Nguva yekutumira: Kubvumbi-17-2021