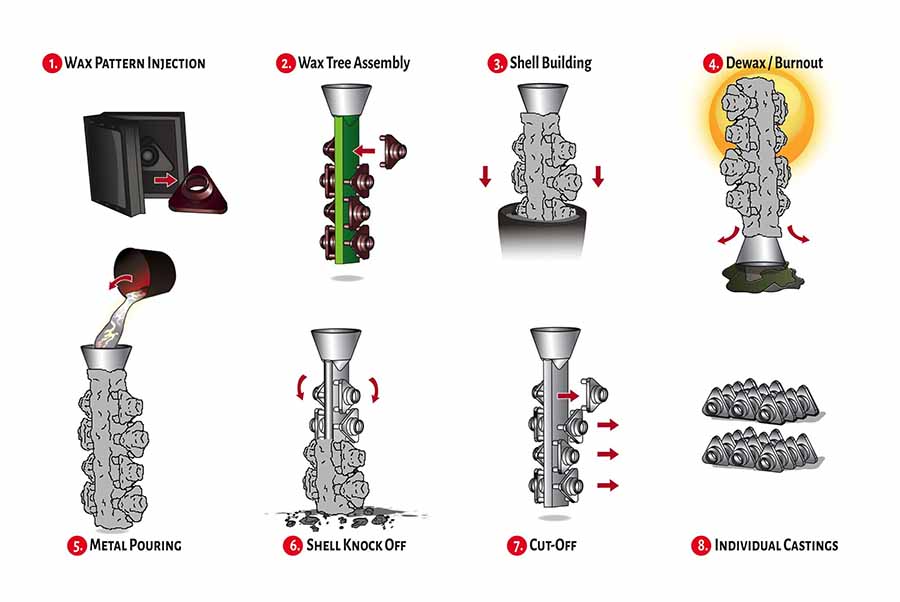

Investment castinginoshandisa mapatani ewakisi anogadzirwa neakakosha uye akasiyana maturusi maererano nemakasheni anodiwa. Mapatani ewakisi (replicas) akakomberedzwa nezvidimbu zvezvinhu zvakasungirirwa zvinoramba zvichigadzira goko rakasimba kuti rimirire simbi yakanyungudutswa nealloys. Kubvisa wakisi kunobvisa wakisi kuitira kuti mhango ine mhango kuitira kuti simbi yakanyunguduka iazadze kuti iite zvikamu zvekukandira zvinodiwa. Ndosaka iyo investment casting ichinzi yakarasika wax casting process. Mune yemazuva ano yekudyara yekukandira yakawanikwa, izvo zvakasungwa zvinonyanya kureva silica sol uye girazi remvura, iro rinogona kuve nechokwadi chepamusoro peiyo.Investment castings. Iyo yekudyara yekukanda maitiro inowanzo shandiswa kugadzira kabhoni simbi castings, alloy simbi castings,Stainless simbi castingsnezvakaumbwa zvendarira. Pano munyaya ino, tinoedza kuunza matanho makuru ekutsvaga mari.

Gadzira Tooling yeWax Jekiseni

Zvinoenderana nezvaidiwa castings uye tichifunga nezve mvumo yemashure-machining uye inogoneka shrinkage, mainjiniya painvestment casting foundry anofanira kugadzira uye kugadzira mold musimbi (iyo inonziwo "kufa") uye zvishandiso zvekugadzira wakisi mapatani.

Kugadzira Patani Yewakisi

Mumazuva anochivako chekukandira wakisi chakarasika, mapatani ewakisi anowanzo gadzirwa nekubaya wakisi mumudziyo wesimbi kana kuti "kufa" nemichina yakakosha yejekiseni. Pakukanda kwakawanda, mudziyo wesilicon unowanzo gadzirwa kubva pachivezwa chemuimbi uye wakisi inobayiwa kana kudirwa mugomba rinobuda.

Wax Tree Assembly

Zvinowanzoita zvisina hupfumi kuita zvidimbu zvidiki chimwe panguva, saka mapatani ewakisi anowanzo kusungirirwa kune wax sprue. Wakisi iri pakati pepatani (ma) nesprue inodaidzwa kuti magedhi, nekuti inotsikirira kwakananga uye kuyerera kweakanyungudutswa alloy muburi rakagadzirwa nepateni. The sprue inoshandisa zvinangwa zviviri

- 1. Inopa nzvimbo inokwirisa kuti iunganidze akawanda mapatani kuita imwe mold, iyo inozozadzwa gare gare nealloy.

- 2. Inopa nzira yekuyerera yealloy yakanyungudutswa muburi rakagadzirwa nemapatani ewakisi.

Shell Building

Nhanho inotevera mukuita ndeyekugadzira goko receramic rakatenderedza muti wewakisi. Goko iri rinozopedzisira rave mold inodirwa simbi. Kuvaka goko, muti unonyikwa mubhati re ceramic kana slurry. Mushure mekunyura, jecha rakanaka kana rinoshandiswa kune yakanyorova. Iyo mold inotenderwa kuoma, uye maitiro anodzokororwa kakati wandei kusvika akaturikidzana ceramic mold, inokwanisa kumira kushushikana kwesimbi yakanyungudutswa uye alloys panguva yekudira.

Dewax / Kupisa

Usati wadira simbi muforoma, wakisi inobviswa nekupisa goko. Izvi zvinowanzoitwa muutsi-dewax autoclave, yakafanana nehombe, indasitiri yekumanikidza cooker. Imwe nzira ndeyekushandiswa kwechoto chemoto, iyo inonyunguduka uye inopisa kubva pawakisi. Wakisi yaigona kuunganidzwa yoshandiswazve kugadzira mapatani ewakisi anotevera. Mazhinji ekudyara mafesheni ekutanga anoshandisa nzira mbiri mukoniti. Moto unopisa unopisa wakisi yasara uye unorapa goko, kugadzirira kugashira simbi yakanyungudutswa nemaaroyi.

Kudira Metal

Simbi isati yadururwa mugomba receramic kana goko, mold inofanopiswa kune imwe tembiricha kudzivirira iyo yakanyungudutswa alloy kubva mukuoma kana kutonhora kubva iyo mold yese isati yazadzwa. Alloy inonyungudutswa mukapu yeceramic (inonzi crucible) uchishandisa nzira inozivikanwa se induction melting. A high frequency electric current inogadzira magineti yakatenderedza alloy, ichigadzira minda yemagetsi mukati mesimbi (eddy currents). Iwo eddy mafungu anopisa alloy nekuda kwekupokana kwemagetsi. Kana iyo alloy inosvika pakupisa kwayo yakatarwa, inodururwa muforoma, uye mold inobvumirwa kutonhora.

Shell Knock Off

Kana ichinge yatonhora, iyo shell zvinhu inobviswa kubva musimbi nenzira dzemuchina senge sando, yakanyanya kudzvanywa mvura inoputika kana tafura yevibratory. Kubvisa Shell kunogonawo kuitwa kemikari, uchishandisa inopisa caustic mhinduro ye potassium hydroxide kana sodium hydroxide, asi nzira iyi iri kupedzwa nekuda kwekunetseka kwezvakatipoteredza uye hutano.

Cheka

Kana iyo shell yabviswa, sprue nemasuwo anochekwa nemaoko kana nechop saw, torch laser yekucheka. Nzvimbo dzekucheka dzinoda kukuyiwa munzvimbo yakanaka.

Individual Castings

Mushure mekunge zvikamu zvabviswa kubva pasprue, uye magedhi abviswa, nzvimbo yacho inogona kupedzwa kuburikidza nehuwandu hwenzira dzakadai sevibratory, media finishing, bhanhire, kugaya maoko, kupurisa. Kupedzisa kunogona kuitwa nemaoko, asi muzviitiko zvakawanda zvinogadzirwa.Kukanda zvikamuzvinozoongororwa, zvinomakwa (kana zvichidikanwa), zvinoiswa mukati uye zvinotumirwa. Zvichienderana nekushandiswa, zvikamu zvekuisa mari zvinogona kushandiswa mu "net shape" yavo kana kupindaMachiningkuitira kunyatsoita nzvimbo.

Nguva yekutumira: Jan-18-2021