OEM tsika Stainless simbi castings inogadzirwa neyakarasika wax investment cast uyeCNC machining masevhisi. Iyo AISI 316 / CF8M simbi isina tsvina inoshandiswa zvakanyanya kugadzira imba yepombi yesimbi isina tsvina kana chivharo chekupedzisira nekuda kwekuita kwayo kwakanaka kwekurwisa ngura.

Simbi isina simbi ine hushoma hwe chromium inosvika 10.5%, zvichiita kuti isarambe iine corrosive liquid environments uye kuoxidation. Iyo inodzivirira zvakanyanya corrosion uye inopfeka inodzivirira, inopa yakanakisa machinability, uye inozivikanwa zvakanyanya nekutaridzika kwayo. Stainless simbi yekukandira mari "inodzivirira kupisa" kana ichishandiswa munzvimbo dzemvura uye mhute iri pasi pe1200°F (650°C) uye "inodzivirira kupisa" kana ichishandiswa pamusoro petembiricha iyi.

Izvo zvigadziko zvealloy zvechero nickel-base kana simbi isina tsvina yekukandira ndeye chromium, nickel, uye molybdenum (kana "moly"). Zvitatu izvi zvinosarudza chimiro chezviyo zvekukanda uye michina uye zvichabatsira mukukanda kugona kurwisa kupisa, kupera, uye ngura.

Nzvimbo yedu inogona kugadziratsika Stainless simbi investment castingszvinoenderana nemagadzirirwo ako chaiwo. Kune zvikamu kubva pamakumi emagiramu kusvika makumi emakirogiramu kana kupfuura, isu tinopa kushivirira kwakasimba uye chikamu chinowirirana kune chikamu kudzokorora.

Kazhinji, simbi isina tsvina inofanira kukandwa neinvestment precision casting processne silica sol sechisungo. Iyo simbi isina tsvina silica sol castings ine yakakwira giredhi rechaiyo pamusoro uye kuita.

Nekuda kwehunhu hwayo hwakasiyana hwemuviri, Stainless simbi castings yakakurumbira mumhando dzakasiyana dzekushandisa, kunyanya idzo dziri munzvimbo dzakaoma. Misika yakajairika yesimbi isina tsvina yekukanda mari inosanganisira mafuta uye gasi, simba remvura, chekufambisa, hydraulic system, indasitiri yezvokudya, hardware uye makiyi, zvekurima ... nezvimwe.

▶ Kugona kweInvestment Casting Foundry

• Kukura Kwepamusoro: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg - 100 kg

• Kwegore Kukwanisa: 2,000 matani

• Bond Materials for Shell Building: Silica Sol, Water Glass nemisanganiswa yawo.

• Kushivirira: Pakukumbira.

▶ Main process ye Investment Casting

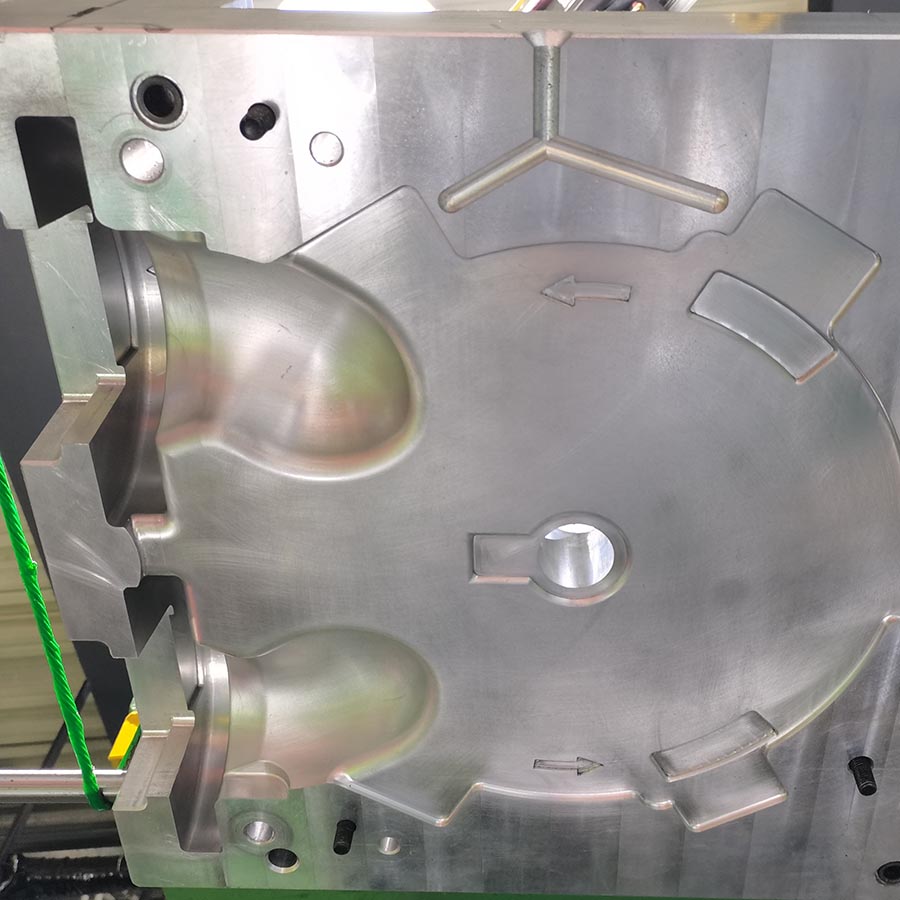

• Mapeteni & Madhizaini Ekushandisa → Kugadzira Metal Die → Jekiseni rewakisi → Slurry Gungano → Kuvaka Shell → Kubvisa Waxing → Kuongorora Kuumbwa Kwekemikari → Kunyunguduka & Kudira → Kuchenesa, Kukuya & Kupfura Kuputika

▶ Maonero AtinoitaYakarasika Wax Castings

• Spectrographic uye manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell uye Vickers kuoma kwekuongorora

• Kuongororwa kwemidziyo yemagetsi

• Low uye zvakajairika tembiricha kukanganisa kuedza

• Kuongororwa kweutsanana

• UT, MT uye RT kuongorora

▶ Post-Casting Maitiro

• Kubvisa & Kuchenesa

• Shot Blasting / Jecha Peening

• Kupisa Kurapa: Kugadzirisa, Kudzima, Kupisa, Carburization, Nitriding

• Surface Treatment: Passivation, Anodizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec.

• Machina: Kutenderedza, Kugaya, Lathing, Kuchera, Kucherekedza, Kukuya.

▶ Zvakanakira Investment Casting Maitiro:

• Yakanakisa uye yakatsetseka pamusoro pekupedzisira

• Tight dimensional tolerances.

• Maumbirwo akaoma uye akaoma kunzwisisa ane dhizaini inoshanduka

• Kukwanisa kukanda madziro matete saka chinhu chakareruka chekukanda

• Kusarudzwa kwakakura kwesimbi uye alloys (ferrous uye isiri-ferrous)

• Draft haidikanwi mukugadzira molds.

• Kuderedza kudiwa kwechipiri machining.

• Kurasa zvinhu zvakaderera.