RMC iChina Stainless steel casting foundry kuita kuti simbi isina tsvina igadzirwe semadhirowa uye zvaunoda, inoshandiswa centrifugal pombi yakavharwa impeller.

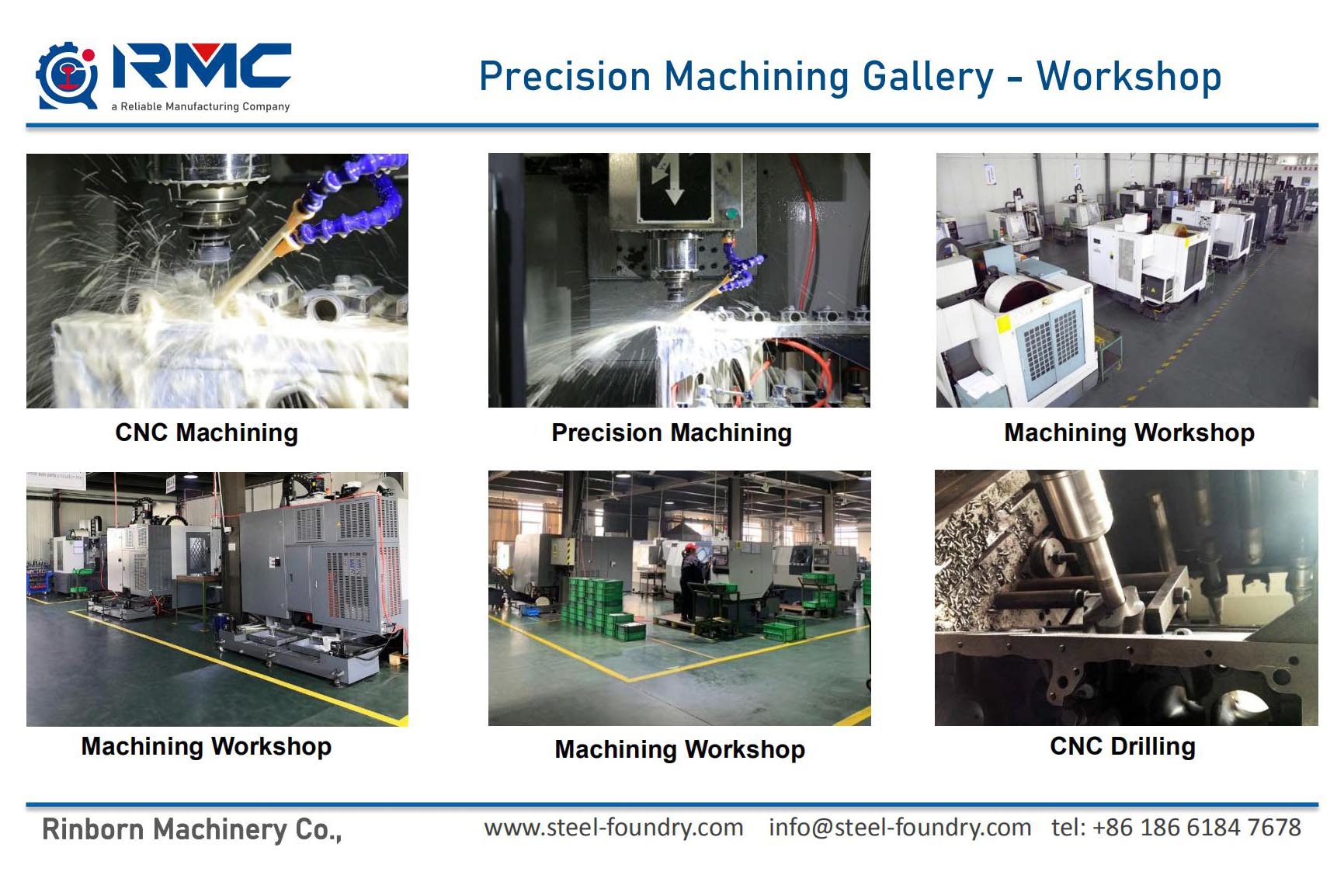

CNC machiningzvinoreva machining process inofambiswa neComputerized Numberical Control (CNC kwenguva pfupi). Inobatsirwa neCNC kusvika pakakwirira uye yakatsiga chokwadi nemutengo wakaderera wevashandi. Machining imhando ipi neipi yemaitiro akasiyana umo chidimbu chemidziyo inochekwa kuita inodiwa chimiro chekupedzisira uye saizi neinodzorwa-yekubvisa zvinhu. Maitiro ane iyi dingindira rakajairika, inodzorwa kubviswa kwezvinhu, nhasi zvave kuzivikanwa pamwe chete se subtractive kugadzira, mumutsauko kubva kune inodzorwa yekuwedzera zvinhu, inozivikanwa seyekuwedzera kugadzira.

Chaizvoizvo izvo zvinorehwa nechikamu chetsanangudzo "zvinodzorwa" zvinogona kusiyana, asi zvinogara zvichireva kushandiswa kwematurusi emuchina (kuwedzera kune maturusi emagetsi nematurusi emaoko). Iyi inzira inoshandiswa kugadzira zvigadzirwa zvesimbi zvakawanda, asi inogona zvakare kushandiswa pazvinhu zvakaita sehuni, mapurasitiki, ceramic, uye macomposites. Iyo CNC machining inovhara akawanda akasiyana maitiro akadai sekugaya, kutendeuka, lathing, kuchera, kukudza, kukuya ... nezvimwe.

| CNC Precision Machining Mano | ||||

| Facilities | Quantity | Size Range | Annual Capacity | General Kururama |

| Vertical Machining Center (VMC) | 48 seti | 1500mm × 1000mm × 800mm | 6000 ton kana 300000 zvidimbu | ±0.005 |

| Horizontal Machining Center (VMC) | 12 seti | 1200mm × 800mm × 600mm | 2000 matani kana 100000 zvidimbu | ±0.005 |

| CNC Machine | 60 seti | Max achitendeuka dia. φ600mm | 5000 matani kana 600000 zvidimbu | |

| Excutive Standard of Casting Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) kana GBT 6414 (China). | ||||

Iyo machining Center inogadzirwa kubva kumuchina weCNC milling. Musiyano mukuru kubva kumuchina weCNC milling ndewekuti machining centre ine kugona kuchinjanisa otomatiki maturusi emuchina. Nekuisa maturusi ezvinangwa zvakasiyana pamagazini yezvishandiso, maturusi emuchina pane spindle anogona kuchinjwa neatomatiki chishandiso chekuchinja mune imwe clamping kuti uone akawanda machining maficha.

Iyo CNC machining Center ndeye yakakwirira-inoshanda otomatiki muchina chishandiso icho chinoumbwa nemichina michina uye CNC system uye yakakodzera kugadzirisa zvikamu zvakaoma. Iyo CNC machining Center parizvino ndeimwe yeanonyanya kushandiswa CNC muchina maturusi munyika ane yakasimba yakazara kugadzirisa kugona. Inogona kupedzisa zvimwe zvekugadzirisa zvemukati mushure mekunge workpiece yakasungwa panguva imwe chete. Kurongeka kwekugadzirisa kwakakwirira. Kune batch workpieces ine yepakati kuomerwa kwekugadzirisa, kushanda kwayo ndeye 5-10 nguva yemidziyo yakajairwa, kunyanya inogona kupedzisa Mazhinji magadzirirwo asingagone kupedzwa nemichina yakajairwa akakodzera kugadziridzwa-chimedu chimwe chine maumbirwo akaomarara uye yakanyanya kurongeka zvinodiwa kana kune diki nepakati batch kugadzirwa kwemarudzi akawanda. Inotarisa mabasa ekugaya, kufinha, kuchera, kubata uye kucheka tambo pane chimwe chinhu, kuitira kuti ive nemhando dzakasiyana dzetekinoroji.

Machining nzvimbo dzakarongedzerwa kuita yakachinjika uye yakatwasuka machining nzvimbo zvichienderana nenzvimbo yavo yepakati panguva yekuruka machining. Yakarongedzerwa zvinoenderana nekushandiswa kwemaitiro: inofinha uye milling machining Center, komputa machining Center. Zvinoenderana neakakosha kupatsanurwa kwemabasa, kune: single workbench, kaviri workbench uye akawanda-workbench machining centre. Machining nzvimbo dzine single-axis, mbiri-axis, matatu-axis, ina-axis, mashanu-axis uye inochinjika misoro, nezvimwe.

CNC machining imhando yekunyatso gadzira ne CNC michina yakadai seyepamusoro machining nzvimbo ine yepamusoro yekupedzisira 5 axis machining centre, 4 axis double platform machining center, kana CNC turning lathes inogonawo kuvandudzwa kuCNC turning centre ine simba rekuchinja zvimwe. kupfuura 15 cutters mukati meimwe yekubata shift; CNC milling machine uye CNC drilling and tapping centers.Precision machining of steel casting yakasiyana nekugadzirwa kwesimbi profile. Precision casting yakatowana chimiro chaicho chezvinodiwa, nekudaro inochengetedza machining akawanda kana ichienzaniswa nemachining kubva kusimbi mbiri. Zvakare nekuda kwechikonzero ichi, isu tinowanzo funga nezve machining pamusoro uye yakakodzera machining mvumo tisati takanda. Kutenga kwedu nguva dzose ndeyekugadzira dhizaini yekukandira pamwe chete nemachining dhizaini kutsanangura nzvimbo yekugadzira uye machining mvumo padhirowa.

RMC investment casting foundry ine 4 axis machining centers, 15 seti yeCNC inotenderedza lathes uye 3 seti ye cnc milling muchina, pamwe nemubatsiri akajairwa kushandura, kugaya, kugogodza, kudhirowa nekugaya michina, isu tine kugona kwekugadzira zvinenge zvese. mhando dzesimbi castings.

| Yakaenzana Giredhi reCast Alloy Simbi kubva Akasiyana Marike | |||||||||

| GROUPS | AISI | W-stoff | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| Low Alloy Steel | 9255 | 1.0904 | 55 Si7 | 250 A53 | 2090 | 55 S 7 | 56Si7 | - | 5SSi8 |

| 1335 | 1.1167 | 36 Mn5 | 150 M 36 | 2120 | 40 m5 | 36Mn5 | SMn 438(H) | - | |

| 1330 | 1.1170 | 28 Mn 6 | 150 M28 | - | 20 M5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Kr 6 | 534 A99 | 2258 | 100 C 6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mwedzi 3 | 1501 240 | 2912 | 15 D 3 | 16 Mo3 | STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220(H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311-Rudzi 7 | - | 40 NCD 2 | F.129 | SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 A16 | - | 18 NCD 6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 Kr4 | 530 A32 | - | 32 C 4 | 35Cr4 | SCr430(H) | 34Cr4(KB) | |

| 5140 | 1.7035 | 41 Kr 4 | 530 A40 | - | 42C 2 | 42 Kr 4 | SCr 440 (H) | 40Cr4 | |

| 5140 | 1.7035 | 41 Kr 4 | 530 A40 | - | 42C 2 | 42 Kr 4 | SCr 440 (H) | 41Cr4 KB | |

| 5140 | 1.7045 | 42 Kr 4 | 530 A40 | 2245 | 42 C 4 TS | F.1207 | SCr440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 Kr 3 | 527 A60 | 2253 | 55C 3 | - | SUP 9(A) | 55Cr3 | |

| 4130 | 1.7218 | 25 CrMo 4 | 1717CDS 110 | 2225 | 25 CD4 | F.1251/55Cr3 | SCM 420 / SCM430 | 25CrMo4(KB) | |

| 4135 (4137) | 1.7220 | 35 CrMo 4 | 708 A 37 | 2234 | 35 CD 4 | 34 CrMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 TS | 42 CrMo 4 | SCM 440 | 41 CrMo 4 | |

| 4140 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 40 CD 4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 CrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10 CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 CrV 4 | 735 A50 | 2230 | 50 CV 4 | F.143 | SUP 10 | 50CrV4 | |

| - | 1.8515 | 31 CrMo 12 | 722 M 24 | 2240 | 30 CD 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Medium Alloy Steel | W1 | 1.1545 | C105W1 | BW1A | 1880 | Y 105 | F.5118 | SK 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100 C 6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 CRV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCrV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M 40 | 2541 | 35 NCD 6 | F.1280 | SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Chishandiso uye Yakakwira Alloy Simbi | D3 | 1.2080 | X210 Cr 12 | BD3 | 2710 | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40 CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z 40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 | X210 CrW 12 | BD6 | 2312 | Z200 CD12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCrV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 2 9 2 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S 45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Yakakwira Tensile Simba Simbi | A128 (A) | 1.3401 | G-X120 Mn 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | GX120Mn12 |

Kugona kweInvestment Casting Foundry:

• Kukura Kwepamusoro: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg - 100 kg

• Kwegore Kukwanisa: 2,000 matani

• Bond Materials for Shell Building: Silica Sol, Water Glass nemisanganiswa yawo.

• Kushivirira: Pakukumbira.

Zvakanakira zveInvestment Casting Zvikamu:

- Yakanakisa uye yakatsetseka pamusoro pekupedzisira

- Tight dimensional tolerances.

- Yakaoma uye yakaoma maumbirwo ane dhizaini inoshanduka

-Kugona kukanda madziro matete saka chinhu chakareruka chekukanda

-Kusarudzwa kwakakura kwesimbi dzakakandwa uye alloys (ferrous uye isiri-ferrous)

- Draft haidiwe mukugadzira molds.

- Deredza kudiwa kwechipiri machining.

- Kurasa zvinhu zvakaderera.

| Zvishandiso zve Investment Casting uyeCNC MachiningpaRMC Foundry | |||

| Category | China Grade | US Giredhi | Germany Giredhi |

| Ferritic Stainless Simbi | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Simbi | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic simbi isina tsvina | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.44404, 1.4404, 9 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Kunaya Kuomesa Stainless Simbi | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Simbi | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Simbi | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

Iyo inonziwo precision machining, iyo CNC machining inogona kusvika pakurongeka kwakanyanya mukushivirira kwegeometical uye kushivirira kwedimensional. Nemichina yedu yeCNC uye Horizontal Machining Centers (HMC) uye Vertical Machining Centers (VMC), tinogona kuzadzisa mamakisi ako ese anodiwa ekushivirira.

| INVESTMENT CASTING TOLERANCES | |||

| Inches | Mamirimita | ||

| Dimension | Kushivirira | Dimension | Kushivirira |

| Kusvika ku0.500 | ±.004" | Kusvika ku12.0 | ± 0.10mm |

| 0.500 kusvika 1.000" | ±.006" | 12.0 kusvika 25.0 | ± 0.15mm |

| 1.000 kusvika 1.500" | ±.008" | 25.0 kusvika 37.0 | ± 0.20mm |

| 1.500 kusvika 2.000" | ±.010" | 37.0 kusvika 50.0 | ± 0.25mm |

| 2.000 kusvika 2.500" | ±.012" | 50.0 kusvika 62.0 | ± 0.30mm |

| 2.500 kusvika 3.500" | ±.014" | 62.0 kusvika 87.0 | ± 0.35mm |

| 3.500 kusvika 5.000" | ±.017" | 87.0 kusvika 125.0 | ± 0.40mm |

| 5.000 kusvika 7.500" | ±.020" | 125.0 kusvika 190.0 | ± 0.50mm |

| 7.500 kusvika 10.000" | ±.022" | 190.0 kusvika 250.0 | ± 0.57mm |

| 10.000 kusvika 12.500" | ±.025" | 250.0 kusvika 312.0 | ± 0.60mm |

| 12.500 kusvika 15.000 | ±.028" | 312.0 kusvika 375.0 | ± 0.70mm |